Have you ever tried creating something amazing with a metal lathe? It feels great to shape metal into wonderful pieces. But what happens when your lathe doesn’t work quite right? One common issue is the tailstock alignment. Getting it just right makes a big difference in how your project turns out.

Imagine you’re working on a cool project, but your tailstock is off. You may end up with a crooked cut or a messy finish. That can be very frustrating for any hobbyist!

Did you know that even tiny adjustments can change your whole outcome? Proper alignment can save you time and material. And it can turn a good project into a great one. So, how can you make sure your tailstock is aligned perfectly?

This article will help you with tips and tricks for hobbyist metal lathe tailstock alignment. Get ready to enhance your lathe skills and take your projects to the next level!

Hobbyist Metal Lathe Tailstock Alignment Tips And Techniques

Hobbyist Metal Lathe Tailstock Alignment

Achieving proper alignment of a hobbyist metal lathe tailstock is crucial for accurate machining. Misalignment can lead to poor cuts and uneven components. Ensure your tailstock is squared to the bed for best results. Regular checks with tools like a dial indicator can save time and frustration. Did you know that even a small misalignment can ruin a project? By focusing on tailstock alignment, you can enhance the precision of your work and enjoy better outcomes.Understanding the Importance of Tailstock Alignment

Explain why tailstock alignment is crucial for precision machining.. Discuss the impact of misalignment on finished projects..Having your tailstock aligned is like having a cupcake with just the right amount of frosting—needed for the perfect finish! Proper alignment ensures precision in machining, allowing your projects to fit together seamlessly. Misalignment, on the other hand, can lead to uneven cuts and messy results. Imagine trying to bake without measuring ingredients; it might turn into a gooey disaster! Keeping your tailstock aligned is key to avoiding these mishaps in your finished projects.

| Effect of Misalignment | Result |

|---|---|

| Uneven Cuts | Incomplete projects that may need to be redone |

| Poor Fit | Parts not working together correctly |

| Increased Wear | More wear and tear on your tools |

So remember, a little adjustment goes a long way!

Common Signs of Tailstock Misalignment

Detail symptoms indicating that tailstock alignment may be off.. Provide examples of how these signs can affect machining accuracy..Misalignment of the tailstock can show obvious signs. Pay attention to these common problems:

- Workpieces producing tapered cuts

- Unusual vibrations during machining

- Inconsistent diameter across the item

These issues can lead to poor finishes and wasted materials. If the tailstock is off, it harms machining accuracy. Fixing it is essential for successful projects.

What are the signs of tailstock misalignment?

Key signs include vibrating tools, uneven cuts, and rough finishes. These problems can make it hard to create precise parts, slowing down your work.

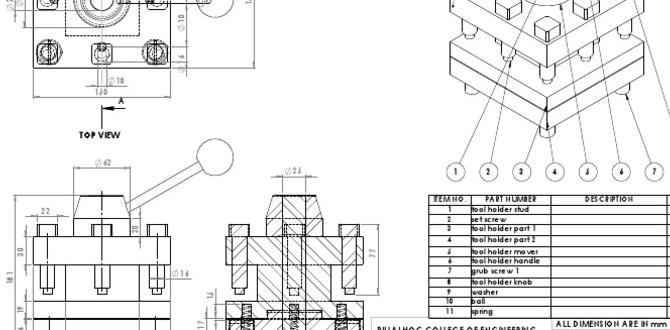

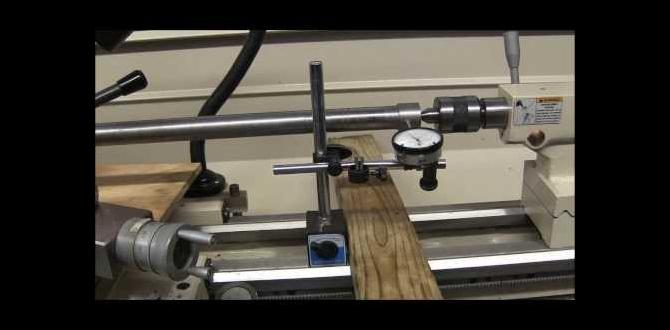

Tools Needed for Tailstock Alignment

List essential tools required for proper alignment.. Explain the function of each tool in the alignment process..For perfect tailstock alignment, you’ll need some trusty tools. First, a dial indicator is key for measuring movement accurately. Think of it as a tiny, honest friend that tells you when things aren’t straight. Next, grab a taper gauge. This tool checks if your tailstock is snug and not wobbling like a three-legged table. Lastly, a wrench helps with adjustments, ensuring your tailstock is as tight as your favorite pair of jeans after Thanksgiving dinner!

| Tool | Function |

|---|---|

| Dial Indicator | Measures alignment precisely |

| Taper Gauge | Checks for snug fitting |

| Wrench | Adjusts tightness |

Step-by-Step Guide to Aligning Your Tailstock

Provide a detailed, sequential process for achieving accurate alignment.. Include tips for troubleshooting common alignment issues during the process..Aligning your tailstock is like tuning up a guitar; it ensures smooth operation. First, check your lathe’s bed for any debris. Next, use a dial indicator to measure alignment. Slowly slide the tailstock while checking the needle. If it wiggles, adjust the tailstock screws until it stays still. Remember: fine-tuning can take time, so be patient! If problems arise, double-check all screws and make small adjustments. Sometimes, less is more!

| Common Issues | Tips |

|---|---|

| Wobbling Movement | Check for debris on the bed. |

| Inconsistent Cuts | Adjust the tailstock screws carefully. |

| Dial Indicator Problems | Ensure it’s properly calibrated. |

Advanced Techniques for Fine-Tuning Tailstock Alignment

Introduce advanced methods for experienced hobbyists to enhance alignment precision.. Offer advice on maintaining tailstock alignment over time..Fine-tuning your tailstock alignment can feel like chasing a greased pig, but with a few advanced techniques, you can master it! First, use a dial indicator to check alignment. This tool is your best buddy for precision. After adjustments, double-check to make sure every measurement lines up. Remember, even experienced hobbyists should regularly maintain tailstock alignment to avoid “wobble-itis.” A simple checklist can help keep things straight. Here’s a quick table for your reference:

| Tip | Action |

|---|---|

| Check Alignment | Use a dial indicator |

| Make Adjustments | Follow proper alignment techniques |

| Regular Maintenance | Inspect every few projects |

Remember, precision is no joke, but it doesn’t hurt to have a laugh while practicing! Your tailstock will thank you!

Frequently Asked Questions about Tailstock Alignment

Address common queries and concerns hobbyists might have regarding alignment.. Include practical solutions and expert tips for improved understanding..Many hobbyists wonder about tailstock alignment. It can seem tricky, but it doesn’t have to be! A common question is, “How can I tell if my tailstock is aligned?” The answer is simple: use a test bar! Place a bar in the lathe and measure at both ends. If it’s off by more than 0.001 inches, it’s time to adjust.

Another frequently asked question is, “What’s the best way to align it?” Start by loosening the tailstock clamp. Then, slide it back and forth, checking the alignment. And remember: measuring twice and cutting once is always good advice, even in lathe work!

| Question | Answer |

|---|---|

| How do I know if my tailstock is aligned? | Use a test bar and measure both ends! |

| What’s the best alignment method? | Loosen the clamp and check the position! |

Resources for Further Learning

Suggest books, articles, and online courses that focus on metal lathe techniques.. Offer community resources, such as forums and local clubs for hobbyists..Diving into the world of metal lathe techniques? You’re in for a fun ride! For starters, check out some great books like “The Metal Lathe” by Tom Elder and “Lathework” by David W. J. G. Dooley. They’re packed with tips! Online courses on platforms like Udemy are also fantastic resources to learn at your own pace. Don’t forget to connect with others! Joining forums like “Practical Machinist” or local clubs can turn your hobby into a community affair. Who knows, you might even find a buddy to share your lathing mishaps with, like that time you almost turned your lathe into a paperweight! Here’s a handy table to get you started:

| Type | Resource |

|---|---|

| Book | The Metal Lathe by Tom Elder |

| Book | Lathework by David W. J. G. Dooley |

| Online Course | Udemy Metal Lathe Courses |

| Forum | Practical Machinist |

| Community Club | Local Metalworking Clubs |

Conclusion

In summary, aligning your hobbyist metal lathe tailstock is crucial for accurate machining. You ensure precise cuts by checking for alignment regularly. Remember to use simple measuring tools and make adjustments as needed. We encourage you to practice these techniques for better results. For more tips, consider reading guides on lathe maintenance. Happy crafting!FAQs

Here Are Five Related Questions On The Topic Of Hobbyist Metal Lathe Tailstock Alignment:To align the tailstock on a metal lathe, you need to make sure it lines up with the main part. First, check that the tailstock sits straight. You can use a ruler or a special tool called a dial indicator for this. Adjust it until everything is straight and even. This helps make better, smoother pieces when you work on the lathe.

Sure! Please provide the question you want me to answer, and I’ll be happy to help.

What Are The Common Signs That Indicate A Misaligned Tailstock On A Metal Lathe?You can see some signs if the tailstock on a metal lathe is not aligned. First, the piece you’re working on might not be straight. Second, it could wobble or shake when you turn it. You might also notice uneven cuts or patterns on the material. Lastly, you may have trouble getting the right size or shape you want.

What Tools And Methods Can Be Employed To Accurately Align The Tailstock Of A Metal Lathe?To align the tailstock of a metal lathe, you can use a few simple tools. First, a dial indicator helps you see if the tailstock is straight. You place it against the end of the lathe and check for any movement. You can also use a test piece, like a rod, to spin and see if it wobbles. Adjust the tailstock until everything is smooth and straight.

How Often Should Hobbyists Check And Realign The Tailstock On Their Metal Lathes For Optimal Performance?You should check the tailstock on your metal lathe every time you start a new project. This helps ensure your work is straight and smooth. If you notice any problems while using it, check and realign it again. Regularly checking it keeps everything working well. It’s a simple way to make sure you have a good experience!

What Are The Potential Consequences Of A Poorly Aligned Tailstock During Machining Operations?If the tailstock isn’t lined up right, your workpiece might wobble. This can make cuts uneven and messy. You could even ruin the piece you’re working on. It can also cause extra wear on the machine. In the end, it can take more time and effort to fix problems.

Can Tailstock Alignment Vary Based On The Type Of Lathe (E.G., Benchtop Vs. Industrial), And If So, How Should The Approach To Alignment Differ?Yes, tailstock alignment can change based on the type of lathe you use. For a small benchtop lathe, you might need to adjust it more often since it’s less sturdy. With a big industrial lathe, it usually stays aligned better. When checking alignment, always take your time and use a simple method, like a ruler or a test piece. This way, you get the best results no matter what lathe you have.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Hobbyist Metal Lathe Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock on a metal lathe, you need to make sure it lines up with the main part. First, check that the tailstock sits straight. You can use a ruler or a special tool called a dial indicator for this. Adjust it until everything is straight and even. This helps make better, smoother pieces when you work on the lathe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Misaligned Tailstock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can see some signs if the tailstock on a metal lathe is not aligned. First, the piece you’re working on might not be straight. Second, it could wobble or shake when you turn it. You might also notice uneven cuts or patterns on the material. Lastly, you may have trouble getting the right size or shape you want.”}},{“@type”: “Question”,”name”: “What Tools And Methods Can Be Employed To Accurately Align The Tailstock Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock of a metal lathe, you can use a few simple tools. First, a dial indicator helps you see if the tailstock is straight. You place it against the end of the lathe and check for any movement. You can also use a test piece, like a rod, to spin and see if it wobbles. Adjust the tailstock until everything is smooth and straight.”}},{“@type”: “Question”,”name”: “How Often Should Hobbyists Check And Realign The Tailstock On Their Metal Lathes For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should check the tailstock on your metal lathe every time you start a new project. This helps ensure your work is straight and smooth. If you notice any problems while using it, check and realign it again. Regularly checking it keeps everything working well. It’s a simple way to make sure you have a good experience!”}},{“@type”: “Question”,”name”: “What Are The Potential Consequences Of A Poorly Aligned Tailstock During Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock isn’t lined up right, your workpiece might wobble. This can make cuts uneven and messy. You could even ruin the piece you’re working on. It can also cause extra wear on the machine. In the end, it can take more time and effort to fix problems.”}},{“@type”: “Question”,”name”: “Can Tailstock Alignment Vary Based On The Type Of Lathe (E.G., Benchtop Vs. Industrial), And If So, How Should The Approach To Alignment Differ?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, tailstock alignment can change based on the type of lathe you use. For a small benchtop lathe, you might need to adjust it more often since it’s less sturdy. With a big industrial lathe, it usually stays aligned better. When checking alignment, always take your time and use a simple method, like a ruler or a test piece. This way, you get the best results no matter what lathe you have.”}}]}