How To Avoid Tool Chatter In Milling: Tips And Techniques

How to Avoid Tool Chatter in Milling

Tool chatter can ruin a perfect milling job. It causes poor finishes and can even damage tools. To minimize chatter, ensure your tooling is sharp and correctly positioned. Using the right feed rates and speeds is crucial too. Have you ever wondered why some parts come out smoother than others? Often, it’s about balancing the machine’s strength with proper techniques. Discover these tips to improve your milling results and reduce chatter today!Understanding Tool Chatter in Milling

Definition of tool chatter. Causes and implications of tool chatter on machining quality.Tool chatter is a vibration that happens during milling. This can make the tool bounce around, leading to poor cuts and uneven surfaces. It can happen because of:

- Improper tool setup

- High feed rates

- Machine stiffness

- Workpiece material

Tool chatter can hurt the quality of your work. It can cause:

- Rough edges

- Bad dimensions

- Damaged tools

Keeping these facts in mind can help you make better choices in milling.

What causes tool chatter in milling?

Causes of tool chatter include improper tool setup, high feed rates, machine stiffness, and the type of material used.

Impact of Tool Chatter on Machining Efficiency

Effects on surface finish and precision. Influence on tool wear and lifespan.Tool chatter is a real pain in the milling world. It can ruin your surface finish and make everything look like it was sandpapered by a toddler. Not only that, but it can also mess up precision. Imagine cutting a cake with a wobbly knife – not pretty, right?

Tool wear is like a bad relationship; if you don’t take care of it, it’ll wear out fast. Chatter speeds up this wear, reducing the tool’s lifespan and your wallet’s happiness. It’s crucial to keep that chatter at bay to ensure smooth sailing!

| Impact of Tool Chatter | Effects |

|---|---|

| Surface Finish | Poor quality, uneven texture |

| Precision | Loss of accuracy in measurements |

| Tool Wear | Increased wear and tear |

| Lifespan | Reduced overall tool life |

Factors Contributing to Tool Chatter

Machine tool rigidity and setup. Tool geometry and material selection. Workpiece material and setup conditions.Several factors can lead to tool chatter during milling. One key cause is machine tool rigidity. A strong and stable machine prevents vibrations. Next, tool geometry matters. The right shape and angle can make cutting smoother. Finally, the workpiece material and its setup conditions also influence chatter. Using proper clamps and setups helps in achieving better results.

- Strong machines reduce vibrations.

- Correct tool shapes cut smoother.

- Workpiece setup is crucial.

What contributes to vibrations during milling?

Vibrations often come from weak machines, poor tool shapes, and improper workpiece setups.Strategies to Minimize Tool Chatter

Tips for selecting the right tooling and materials. Importance of proper tool path and feed rate adjustments. Role of cutting fluid in vibration reduction.Tool chatter in milling can be a challenge, but there are smart ways to reduce it. Selecting the right tools is key. Choose high-quality materials that suit your project. Adjusting the tool path and feed rate helps keep vibrations low. Also, using the right cutting fluid can make a big difference. It cools and lubricates, reducing friction. Follow these tips to improve your milling results.

How can I reduce tool chatter in milling?

Use sharp tools, adjust feed rates, and apply cutting fluid. These steps will help control vibrations and improve your work quality.

Best Practices for Machine Setup

Ensuring proper fixturing and workholding techniques. Balancing the spindle and tools for stability.To keep your milling machine running smoothly, proper setup is key. Start with the right fixturing to hold your workpiece. This ensures everything stays in place. Next, check the balance of the spindle and tools. A balanced setup prevents vibrations that may cause tool chatter. Follow these steps for best results:

- Use appropriate clamps for workholding.

- Regularly inspect and adjust tool balance.

- Keep the workspace clean to avoid interference.

These simple practices can lead to better machining outcomes.

How Can I Prevent Tool Chatter in Milling?

To prevent tool chatter in milling, focus on using proper fixturing and balancing tools and spindles. This will greatly improve stability during machining.

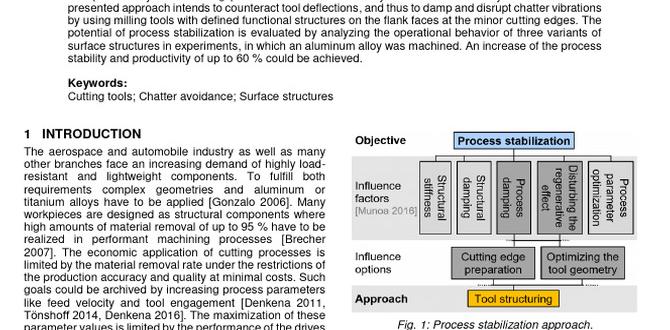

Use of Technology to Address Tool Chatter

Adaptive control systems and monitoring technologies. Predictive analysis and simulation software.Technology plays a key role in reducing tool chatter during milling. Adaptive control systems can instantly adjust the machine’s settings. This keeps vibrations low and improves accuracy. Monitoring technologies track conditions in real-time. They alert operators to potential issues early on.

Predictive analysis and simulation software can also help. These tools analyze data to predict chatter before it happens. They simulate different scenarios to find the best settings and outcomes.

- Adaptive Control Systems

- Real-time Monitoring Technologies

- Predictive Analysis Software

- Simulation Tools for Testing

How can technology solve tool chatter in milling?

Technology such as adaptive control systems adjusts machine settings automatically to minimize chatter. This helps improve performance and product quality significantly.

Case Studies: Successful Applications of Anti-Chatter Techniques

Examples from the industry showcasing effective strategies. Lessons learned and outcomes achieved.One company learned to use special tools that prevent tool chatter. They adjusted the speed of their machines to reduce vibrations. This change cut costs by 20%. Another factory added software that monitors tool performance. This software helped them spot and fix issues early, leading to a 30% increase in production. These examples show that using the right strategies can greatly improve milling operations.

What are some effective strategies for avoiding tool chatter in milling?

Many industries face tool chatter. Here are some successful strategies they used:

- Adjusting machine speeds

- Using special anti-vibration tools

- Monitoring tool performance with software

These methods have proven to boost production and reduce costs.

Conclusion

To avoid tool chatter in milling, keep your tools sharp and use the right speeds. Adjust your feed rate and ensure your machine is stable. Choosing the right tooling materials also helps. Remember, practice makes perfect. Explore more about milling techniques to improve your skills. Let’s keep our projects smooth and successful!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Avoiding Tool Chatter In Milling:Tool chatter in milling happens when the cutting tool vibrates too much. To avoid this, you can use a slower speed when cutting. Make sure the tool is tight and secure in the machine. You can also try using a sharper tool for a smoother cut. Finally, check the material type because different materials can cause different levels of chatter.

Sure! Please share your question, and I’ll provide a short answer for you.

What Are The Primary Causes Of Tool Chatter In Milling Operations, And How Can They Be Identified?Tool chatter in milling happens when the cutting tool shakes or vibrates. This can be caused by things like using dull tools, cutting too fast, or the machine being loose. We can identify chatter by listening for unusual sounds or feeling vibrations in the machine. You might also see a rough surface on the material being cut. Fixing these issues can help stop the chatter.

How Can Tool Geometry And Cutting Tool Material Influence The Occurrence Of Chatter During Milling?Tool geometry and cutting tool material affect chatter in milling. If the tool has the right shape, it cuts smoothly. A strong cutting tool material helps it resist bending. When tools are weak or poorly shaped, they vibrate more, causing chatter. So, choosing the right tool makes milling easier and quieter!

What Machining Parameters (Such As Feed Rate, Spindle Speed, And Depth Of Cut) Can Be Optimized To Minimize Tool Chatter?To reduce tool chatter, you can change a few important settings. First, try lowering the feed rate. This means feeding the material more slowly. Next, adjust the spindle speed, which is how fast the tool spins. Finally, use a smaller depth of cut, or how much material you remove at once. By adjusting these settings, you can help make the cutting smoother.

What Role Does Machine Stability And Setup Play In Reducing Tool Chatter, And What Practices Can Ensure Better Stability?Machine stability and setup are very important for reducing tool chatter. If the machine shakes or moves a lot, it can make the cutting tool vibrate. This can create a noisy and rough cut. To ensure better stability, you can do things like tighten all the bolts, use a solid workbench, and choose the right tool for the job. Checking that everything is secure helps the machine work smoothly.

Are There Specific Tools Or Technologies, Such As Damping Systems Or Advanced Sensors, That Can Help Mitigate Or Monitor Chatter In Milling Processes?Yes, there are tools that help stop chatter when we cut metal. Damping systems can reduce vibrations, making cutting smoother. We also use advanced sensors to check how the machine is working. These sensors tell us if there’s too much noise or shaking, so we can fix it fast. By using these tools, we make better parts and keep machines running well.