Have you ever watched a milling machine in action? Those sharp milling cutters spin quickly. They help shape metal into amazing forms. But what if those cutters are out of balance? Suddenly, that smooth operation can turn shaky and unsafe.

Balancing milling cutters feels like a puzzle. You want everything just right. Without balance, your machine can wear out faster. Plus, it may cause harm to the workpiece.

Imagine standing at a carnival. You see a game where you must hit the target just right to win a prize. Balancing milling cutters is similar. You need precision to achieve great results.

In this article, we will explore how to balance milling cutters effectively. We will break it down into simple steps. So, whether you’re a beginner or an expert, you’ll find useful tips. Ready to unlock the secrets of smooth milling? Let’s dive in!

How To Balance Milling Cutters For Optimal Performance

How to Balance Milling Cutters

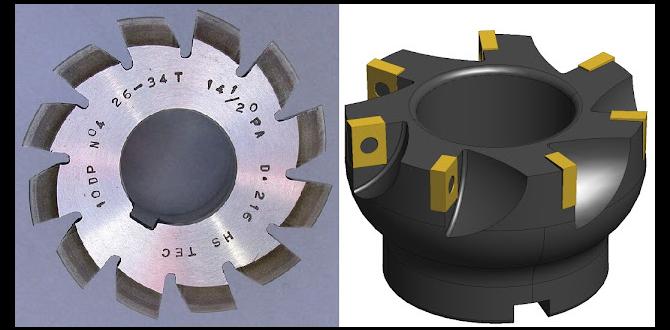

Balancing milling cutters is essential for smooth operation. When cutters are not balanced, they can cause vibrations that lead to poor performance. To balance them, check for uneven weight distribution. Using a balancing machine can help identify these issues. Imagine a ride on a bumpy road; that’s how cutting feels when equipment is unbalanced. Regular checks can extend the cutter’s life and improve the quality of your work. A well-balanced cutter saves time and money, making your projects more efficient!Understanding the Importance of Balancing Milling Cutters

Explanation of milling cutter dynamics and the impact of unbalance.. Benefits of balanced cutters in terms of precision, tool life, and machine stability..When milling cutters spin, they create forces that can affect how they work. If they are not balanced, the cutter can vibrate and wobble. This can lead to problems like uneven cuts and quicker wear. On the other hand, balanced cutters help with:

- Precision: Balanced cutters make exact cuts, which helps in producing better parts.

- Tool life: These cutters last longer, saving time and money.

- Machine stability: They run smoother, reducing the risk of machine damage.

In short, keeping milling cutters balanced improves performance and safety, which is essential for good results.

How does unbalance affect milling cutters?

Unbalance causes vibrations that lead to uneven cuts and quicker wear on tools. This can increase repair costs and decrease product quality.

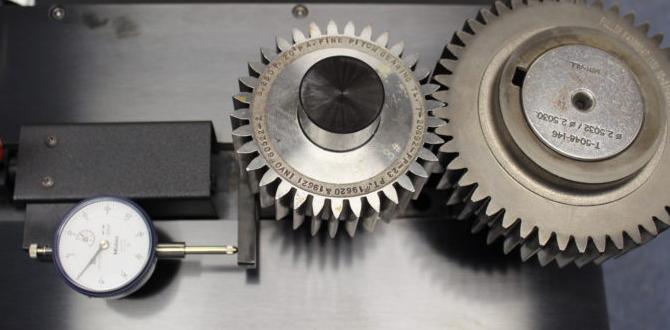

Measurement Techniques for Detecting Imbalance

Detailed methods for checking cutter balance (static vs. dynamic).. Best practices for obtaining accurate measurements..To spot imbalance in milling cutters, we use two clever tricks: static and dynamic balancing. Static balancing checks if the cutter is level while resting. Imagine a seesaw. If one side dips, it needs a fix! Dynamic balancing is like checking how it spins. This method looks for wobbles when the cutter turns. For accuracy, always keep your tools clean and measurements precise. Think of it as checking your cake layers before frosting: nobody wants a lopsided dessert!

| Measurement Technique | Description |

|---|---|

| Static Balancing | Checking stability while stationary. |

| Dynamic Balancing | Assessing balance during rotation. |

For best results, repeat measurements multiple times. Like finding the perfect cookie recipe, practice makes perfect! Happy balancing!

Step-by-Step Guide to Balancing Milling Cutters

Comprehensive process for balancing cutters, including setup and execution.. Tips for achieving optimal balance during the balancing process..To balance milling cutters, start by setting up your equipment on a stable surface. Place the cutter in a balancing machine. This machine helps you find any heavy spots. To execute properly, do these steps:

- Check the cutter for chips or wear.

- Align it correctly in the machine.

- Run the machine to see where adjustments are needed.

- Make small adjustments, and retest until balanced.

For the best results, ensure the setup is level. Keep going until it’s perfect! A well-balanced cutter cuts better and lasts longer. Remember, a careful balance can save time and effort in the future.

What tools do I need to balance milling cutters?

You’ll need a balancing machine and basic tools like wrenches and a scale to adjust the cutter. These tools help make your work easier.

Common Mistakes to Avoid When Balancing Milling Cutters

Identification of frequent errors made during balancing.. Consequences of improper balancing and how to mitigate them..Many people make simple mistakes when balancing milling cutters. One common error is not checking the cutter’s weight distribution accurately. This can lead to wobbling, which is like trying to ride a bicycle with one flat tire—dangerous and awkward! Another mistake is ignoring vibrations. If you feel a dancer’s rhythm in your machine, it’s time to take a look. To avoid these blunders, always double-check your work and keep your tools in tip-top shape!

| Common Errors | Consequences | How to Avoid |

|---|---|---|

| Ignoring weight distribution | Wobbling and tool wear | Always measure before use |

| Neglecting vibrations | Decreased performance | Monitor for unusual sounds |

Maintenance Tips for Balanced Milling Cutters

Suggested maintenance practices to ensure ongoing balance.. Signs that indicate a need for rebalancing and how to address them..Taking care of milling cutters helps keep them balanced. Regular maintenance is essential. Check for uneven wear or damage often. This ensures better performance. Here are some key practices:

- Clean cutting edges regularly.

- Inspect for chips or cracks.

- Store them safely to avoid damage.

Watch for signs of imbalance, like vibrations or unusual noises. If you spot these, it’s time to rebalance. Address them promptly to maintain efficiency.

What are the signs that milling cutters need rebalancing?

Vibrations or noise during use are clear signs of imbalance. If you notice changes in cutting quality, it’s time to check the balance too.

Case Studies: Successful Balancing of Milling Cutters

Realworld examples demonstrating the impact of proper balancing.. Lessons learned and best practices derived from case studies..Balancing milling cutters can make a big difference. One case involved a factory that struggled with broken tools. After balancing, tool life improved by 30%! That’s like getting an extra cookie in your lunch! Another company reduced vibration and noise by 50%. Their machines were happier, and so were the workers!

From these stories, we learned that proper balancing keeps tools safe and enhances productivity. Best practices include regular checks and keeping records. So, if you want happy milling cutters, remember: a little balance goes a long way!

| Case Study | Before Balancing | After Balancing |

|---|---|---|

| Factory A | Broken tools, low efficiency | 30% longer tool life |

| Company B | High vibration, noise | 50% less noise |

Conclusion

In summary, balancing milling cutters is essential for better performance and longer tool life. Make sure to check for wear and damage regularly. Use the right equipment to balance them effectively. Remember, balanced cutters reduce vibrations and improve accuracy. For more details, keep reading or try balancing your cutters at home. You’ll see the difference!FAQs

Sure! Here Are Five Related Questions On The Topic Of Balancing Milling Cutters:Balancing milling cutters is important for smooth cutting. If they aren’t balanced, they can vibrate and cause problems. You can balance them by adding or removing weight. We need to check them before using to keep everything safe. It helps our tools last longer and work better!

Sure! Just ask your question, and I’ll help you with a simple answer.

What Are The Main Causes Of Vibration In Milling Operations And How Does Balancing Help Reduce Them?Vibration in milling happens for a few reasons. First, it can come from an unbalanced tool or part. Second, if the machine isn’t set up properly, it can shake. Lastly, worn-out parts can also cause problems. Balancing helps by making sure everything spins evenly. This way, the machine runs smoother and doesn’t shake as much.

What Techniques Can Be Employed To Achieve Precise Balancing Of Milling Cutters?To balance milling cutters, you can use a few methods. First, you can check if they are heavy on one side. If they are, you adjust the weight by adding or removing small pieces. You can also use a balancing machine to help find the right spot. Finally, always test it out before using it for big jobs!

How Often Should Milling Cutters Be Checked And Balanced To Ensure Optimal Performance?You should check and balance milling cutters regularly. It’s best to do this every few weeks or after heavy use. This helps them work better and last longer. If you notice vibrations or problems, check them right away. Keeping them in good shape is important for safe and effective cutting.

What Tools Or Equipment Are Necessary For Effectively Balancing Milling Cutters?To balance milling cutters, you need a few important tools. First, you need a balancing machine to check how evenly the cutter spins. You also need weights to add or remove for balance. A tool holder keeps the cutter steady while you work. Finally, you need measuring tools to see if it’s balanced just right.

How Does Improper Balancing Of Milling Cutters Affect The Overall Lifespan Of The Tooling And The Quality Of The Workpiece?When milling cutters are not balanced properly, they can wear out faster. This means we have to replace them sooner. Also, if they wobble, they can make rough and uneven parts. This affects the quality of the workpiece we make. Taking the time to balance them keeps our tools and workpiece better for longer.