Choosing the right metal lathe design can feel overwhelming. Have you ever looked at a pile of designs and wondered which one is best for you? It’s a bit like picking a bicycle. Each bike serves a different purpose. Some are for racing, and others for mountain trails. The same goes for metal lathes in CAD design.

Imagine wanting to create a unique piece of art or a custom tool. You need a metal lathe that suits your project. But how do you find the right one? Understanding basic requirements and your project goals is key.

Did you know that metal lathes come in various sizes and styles? Some can even turn wood! As you read this article, you’ll discover helpful tips on how to choose metal lathe CAD design that fits your needs. Let’s dive in!

How To Choose Metal Lathe Cad Design For Your Projects

How to Choose Metal Lathe CAD Design

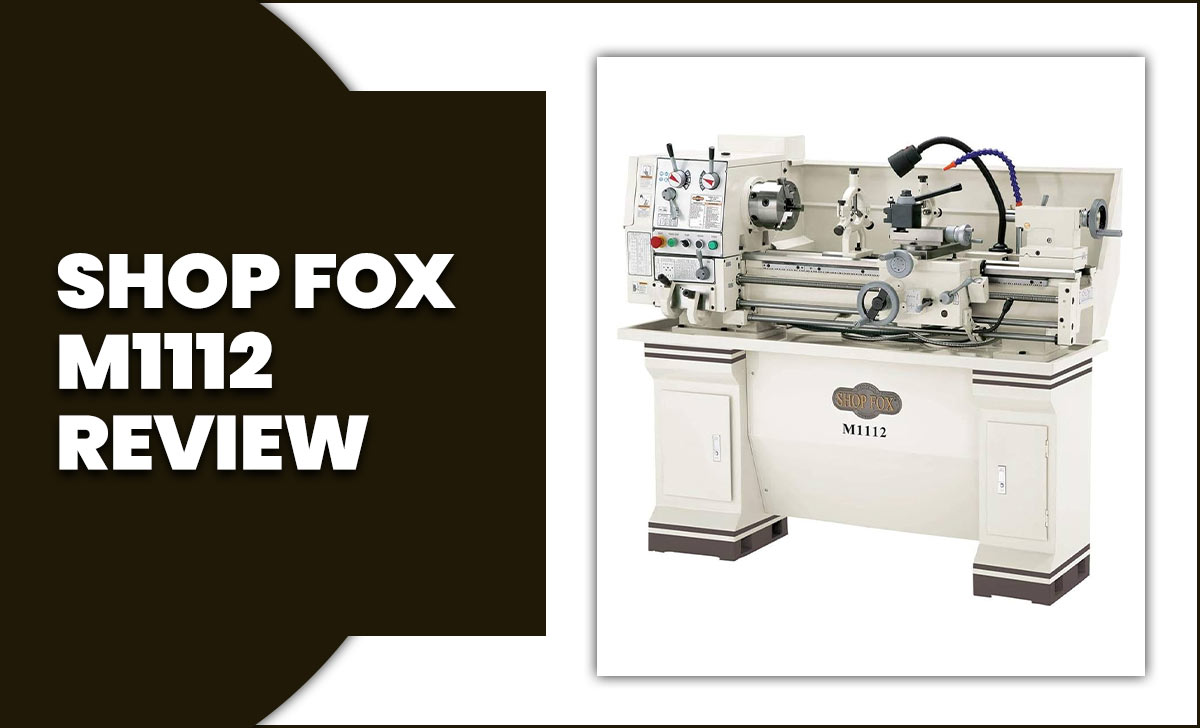

Selecting the right metal lathe CAD design can make a big difference in your projects. Start by understanding your requirements. Consider the materials you’ll use and the size of your workpieces. Have you thought about what features are essential? Look for designs that offer versatility and precision. A surprising fact is that even beginner-friendly designs can lead to professional-grade results. Choosing wisely now means smoother work and better creations later!Understanding Metal Lathes

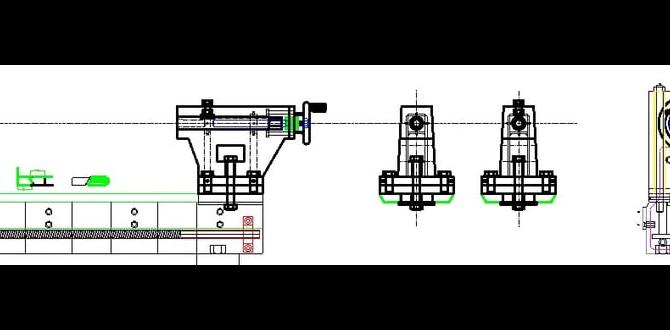

Definition and function of a metal lathe. Importance of CAD design in metal lathe projects.A metal lathe is a machine used to shape metals. It works by spinning the metal as a tool cuts into it. This helps make parts round or smooth. The design of the lathe is very important. CAD design helps plan and create these machines. It shows how everything fits together. Without good design, projects could fail. CAD makes it easier to visualize and test ideas before building anything. This saves time and materials.

What is a metal lathe used for?

A metal lathe is used for creating precise metal parts for various projects, like tools or machinery.What is CAD?

- CAD stands for Computer-Aided Design.

- It helps in planning and designing metal lathe projects.

- Using CAD can improve accuracy and reduce waste.

Key Features to Consider in Metal Lathe CAD Design

Size and capacity of the lathe. Available tooling options and compatibility.Picking the right metal lathe CAD design is like choosing a pizza topping—size and capacity matter! A larger lathe can handle hefty projects, while a smaller one is easy to fit in tight spaces. Watch out for tooling options too; it’s essential to select a lathe that works with your existing tools. You wouldn’t want a surfboard when you’re looking for a skateboard!

| Feature | Importance |

|---|---|

| Size | Fits your workspace and project needs |

| Capacity | Allows for various sizes of materials |

| Tool Compatibility | Works with tools you already have |

Remember, a lathe is an investment. Choose wisely, and don’t end up with a “one-size-fits-none” situation!

Software Options for Metal Lathe CAD Design

Popular CAD software options for metalworking. Comparing features and capabilities of leading software.Many people use CAD software for metal lathe design. Some popular options include:

- AutoCAD: Great for 2D and 3D drawings.

- SolidWorks: Offers strong modeling tools.

- Fusion 360: Combines design and simulation features.

- Inventor: Excellent for complex assemblies.

Each software has special features that fit different needs, whether you want to design simple parts or complex machines. Choosing the right program can make your project easier and more fun.

What should I consider when choosing CAD software for metal lathes?

Think about your design needs and skill level. Some software is easy to learn, while others provide advanced features for experienced users. Check if the software can handle the designs you want to create.

Factors Influencing Your Metal Lathe CAD Design Choice

Budget considerations. Required precision and complexity of designs.Choosing a metal lathe CAD design? Let’s talk about two big things that can help you pick the right one: budget and precision. Money matters! You don’t want to spend all your allowance on a fancy lathe if a simpler one will do the job. And about precision, it’s like baking cookies; if your measurements are off, you might end up with cookie soup! Once you decide how precise you need to be, it gets easier.

| Factor | Consideration |

|---|---|

| Budget | Stick to your wallet! Choose wisely. |

| Precision | Measure once, cut twice—just kidding, cut once! |

Common Mistakes When Choosing Metal Lathe CAD Designs

Pitfalls to avoid in material selection and design processes. Misjudging project requirements and specifications.Choosing the right metal lathe CAD design is important, but mistakes can happen. Here are some pitfalls to avoid:

- Material selection: Picking the wrong material can lead to problems in your project.

- Project requirements: Misunderstanding project needs can waste time and money.

- Specifications: Ignoring specifications may cause your design to fail.

Always double-check your choices to be successful. This way, you can prevent mistakes and create a great design.

What should I avoid when choosing CAD designs?

To avoid issues, ensure you understand your project’s material and design needs. Take time to review specifications.

Best Practices for Effective CAD Design Workflow

Tips for streamlining the design process. Importance of collaboration and feedback in design.Streamlining your design process helps you finish faster. Start by breaking tasks into smaller steps. This makes the work easier. Use libraries for parts and templates. They save time and keep designs neat. Collaboration is key too. Sharing ideas lets others give feedback. Feedback improves designs and makes them more effective.

- Work in small teams.

- Organize regular check-ins.

- Use design reviews for feedback.

How can I get feedback on my designs?

Ask peers for their thoughts and share designs often. This helps catch mistakes early. It also gives fresh perspectives. Use digital tools to gather feedback easily.

Future Trends in Metal Lathe CAD Design

Innovations in CAD technology for metalworking. Impact of automation and smart technology on lathes.New ideas are changing how metal lathe CAD designs work. Innovative software tools make it easier to shape metal precisely. Smart technology is now common. Many lathes run on their own. This saves time and cuts costs. Plus, machines can adjust settings automatically for better results. Here are some key trends:

- Advanced 3D modeling tools.

- Integration of Artificial Intelligence.

- Real-time data and analytics.

These changes mean lathes will keep getting better. It’s an exciting time for metalworking!

What are the latest advancements in metal lathe CAD design?

Latest advancements include integration of AI, improved 3D modeling, and automation in workflows.Resources for Further Learning and Support

Recommended books, courses, and online communities. Where to find additional design templates and support tools.Learning about metal lathe CAD design can be exciting! Here are some great resources to help you dive deeper:

- Books: Look for titles on machining and CAD design. Authors like Michael A. Smith provide clear insights.

- Courses: Platforms like Udemy and Coursera offer engaging classes to boost your skills.

- Online Communities: Join forums like Reddit and Facebook groups. You’ll meet experienced makers!

You can find design templates on websites like Thingiverse. They have plenty of examples ready for you!

Where can I find metal lathe CAD design templates?

Explore platforms like GrabCAD and TurboSquid for CAD templates. They have a variety that fits different needs!

Conclusion

In summary, choosing a metal lathe CAD design involves understanding your project needs and budget. Consider the lathe’s size, features, and compatibility with your materials. Don’t forget to check online resources and user reviews for more insights. Now, explore different designs and tools to find what works best for you. Happy designing!FAQs

Sure! Here Are Five Related Questions On The Topic Of Choosing Cad Designs For A Metal Lathe:Sure! Here are five questions about choosing CAD designs for a metal lathe. We want to pick designs that help us make shapes from metal. First, think about what you want to create. Then, check if the design fits the tools you have. It’s also good to look for designs that are easy to follow. Finally, make sure the design is fun and interesting for you!

Sure! Please ask your question, and I will answer it following your guidelines.

What Key Specifications Should I Consider When Selecting A Cad Design For A Metal Lathe?When choosing a CAD design for a metal lathe, you should think about a few things. First, check the size. Make sure it fits where you want to use it. Next, look at the materials. They should be strong enough for metal work. Finally, check for features like ease of use. You want it to be simple and fun to work with!

How Can I Assess The Compatibility Of A Cad Metal Lathe Design With My Existing Machinery And Tools?To check if a CAD metal lathe design fits with your tools, start by measuring your current machines. Look at the space where you will place the lathe. Compare the sizes and weights between your tools and the new lathe. Also, check if you can connect them easily, like fitting puzzle pieces. This way, you can see if the new lathe will work well with what you already have.

What Common Design Features Should A Metal Lathe Cad Model Include To Ensure Versatility And Efficiency?A good metal lathe model should include a sturdy base to keep it steady. It should have adjustable speeds for different jobs. We also need a tool holder that can change tools easily. A clear user interface helps us understand and use it better. Lastly, adding safety features keeps us safe while we work.

Are There Particular Software Platforms That Are Recommended For Creating Or Modifying Metal Lathe Cad Designs?Yes, there are some good software programs for metal lathe designs. We can use TinkerCAD, which is easy to learn. Another option is Fusion 360, which has more features. Both help you create and change designs easily. You can pick one based on what you need!

How Can I Evaluate The Manufacturability And Cost-Effectiveness Of A Metal Lathe Based On Its Cad Design?To evaluate a metal lathe’s CAD design, you can look at a few key things. First, check if the parts can be easily made. Complex shapes might cost more to produce. Next, think about the materials used; some are cheaper than others. Finally, consider the time it will take to make the lathe. The quicker it is to build, the less it will cost.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Choosing Cad Designs For A Metal Lathe:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about choosing CAD designs for a metal lathe. We want to pick designs that help us make shapes from metal. First, think about what you want to create. Then, check if the design fits the tools you have. It’s also good to look for designs that are easy to follow. Finally, make sure the design is fun and interesting for you!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I will answer it following your guidelines.”}},{“@type”: “Question”,”name”: “What Key Specifications Should I Consider When Selecting A Cad Design For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a CAD design for a metal lathe, you should think about a few things. First, check the size. Make sure it fits where you want to use it. Next, look at the materials. They should be strong enough for metal work. Finally, check for features like ease of use. You want it to be simple and fun to work with!”}},{“@type”: “Question”,”name”: “How Can I Assess The Compatibility Of A Cad Metal Lathe Design With My Existing Machinery And Tools?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if a CAD metal lathe design fits with your tools, start by measuring your current machines. Look at the space where you will place the lathe. Compare the sizes and weights between your tools and the new lathe. Also, check if you can connect them easily, like fitting puzzle pieces. This way, you can see if the new lathe will work well with what you already have.”}},{“@type”: “Question”,”name”: “What Common Design Features Should A Metal Lathe Cad Model Include To Ensure Versatility And Efficiency?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A good metal lathe model should include a sturdy base to keep it steady. It should have adjustable speeds for different jobs. We also need a tool holder that can change tools easily. A clear user interface helps us understand and use it better. Lastly, adding safety features keeps us safe while we work.”}},{“@type”: “Question”,”name”: “Are There Particular Software Platforms That Are Recommended For Creating Or Modifying Metal Lathe Cad Designs?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some good software programs for metal lathe designs. We can use TinkerCAD, which is easy to learn. Another option is Fusion 360, which has more features. Both help you create and change designs easily. You can pick one based on what you need!”}},{“@type”: “Question”,”name”: “How Can I Evaluate The Manufacturability And Cost-Effectiveness Of A Metal Lathe Based On Its Cad Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To evaluate a metal lathe’s CAD design, you can look at a few key things. First, check if the parts can be easily made. Complex shapes might cost more to produce. Next, think about the materials used; some are cheaper than others. Finally, consider the time it will take to make the lathe. The quicker it is to build, the less it will cost.”}}]}