Have you ever wondered how machine shops create those perfectly flat surfaces? It’s all about tools like the fly cutter. This handy tool can smooth out materials quickly. But how do you use a fly cutter in milling? It might seem tricky at first, but it’s not as hard as it looks.

Imagine you are in a workshop. You see workers using a fly cutter, making their jobs easier. They achieve flat, even surfaces that make their projects shine. Isn’t that cool? With a little practice, you can learn to use this tool too!

In this article, we’ll dive into simple steps and fun tips. You will discover how to master the fly cutter and improve your milling skills. Ready to level up your machining game?

How To Use A Fly Cutter In Milling: A Step-By-Step Guide

How to Use a Fly Cutter in Milling

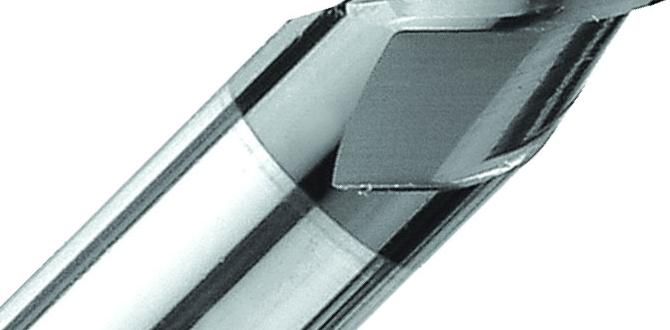

Using a fly cutter in milling can greatly improve your projects. A fly cutter is a simple tool that creates flat surfaces on metal or wood. It has one cutting tool and spins around its axis. To use it, securely mount your material and set the cutter depth. Start the machine and move slowly for the best finish. Did you know that fly cutters can create larger cuts than standard end mills? This makes them a valuable addition to any workshop.What is a Fly Cutter?

Definition and purpose of a fly cutter in machining.. Comparison to other cutting tools used in milling..A fly cutter is a special tool used in machining to create smooth surfaces on materials. It has a single cutting edge and can cover large areas quickly. This tool is great for making flat surfaces, unlike some other cutting tools that only make narrow cuts.

- Purpose: Grind flat surfaces smoothly.

- Comparison: More efficient than end mills for bigger projects.

- Flexibility: Can adjust to different shapes and sizes.

What are the main benefits of using a fly cutter?

Using a fly cutter helps save time and creates fewer burrs compared to other tools. It is cost-effective too since it uses one cutter to do more work.

Components of a Fly Cutter

Description of the main parts and their functions.. Materials commonly used for fly cutter construction..A fly cutter has a few important parts that make it work well. First, there’s the tool holder, which keeps everything in place. It’s like a superhero cape and holds the cutting tool tight. Then, we have the cutting head, where the actual magic happens. This part shapes the material like a sculptor. Lastly, the shaft connects everything and spins it around.

Typically, fly cutters are made from tough materials like high-speed steel or carbide. These materials are hard enough to slice through metal like butter. Here’s a fun fact: without these sturdy materials, cutting would be more challenging than solving a Rubik’s cube blindfolded!

| Component | Function | Common Materials |

|---|---|---|

| Tool Holder | Holds the cutting tool stable | High-speed steel, carbide |

| Cutting Head | Shapes the material | Carbide, HSS |

| Shaft | Connects components and rotates | Steel |

Choosing the Right Fly Cutter

Factors to consider when selecting a fly cutter for a specific job.. Recommendations for various applications and materials..Choosing the right fly cutter can make a big difference in your milling tasks. Here are some important factors to think about:

- Material type: Different materials need different cutters. For hard metals, use a tougher cutter.

- Diameter: Larger diameters cut wider areas. Pick one that fits your job.

- Quality: High-quality cutters give better results and last longer.

For wood, a wide fly cutter works well. For metal, a sturdier design is best. Always match the cutter to your project for the best finish.

What should I look for in a fly cutter?

Look for material compatibility, proper diameter, and quality when selecting a fly cutter. These factors ensure better performance and longer life for your tool.

Setting Up the Fly Cutter

Stepbystep guide on setting up a fly cutter on a milling machine.. Importance of proper alignment and tightening techniques..First, make sure you have all your tools at hand. Grab your fly cutter, a wrench, and a safety shield—because safety first, right? Start by placing the fly cutter in the spindle of your milling machine. Next, tighten the chuck firmly. Make sure it feels snug, like a hug from your favorite teddy bear. Proper alignment is super important. A crooked cutter can create more trouble than a squirrel in a nut factory! Finally, double-check your settings before turning on the machine. Remember, a balanced cutter means smoother cuts!

| Step | Action |

|---|---|

| 1 | Gather all necessary tools |

| 2 | Place the fly cutter in the spindle |

| 3 | Tighten the chuck snugly |

| 4 | Check alignment |

| 5 | Double-check your settings |

Operating the Fly Cutter

Techniques for effective use of a fly cutter during milling.. Common mistakes to avoid while operating a fly cutter..To operate a fly cutter effectively, follow these techniques: Set the right speed for the material. Use smooth, steady movements. Ensure the cutter is sharp for best results. Avoid too much pressure; let the tool do its job. Common mistakes include forgetting to check for tightness in the tool holder and not adjusting the depth correctly. This can lead to uneven cuts. Remember to keep your workspace clean and organized.

What are tips for using a fly cutter?

Tips include using the right speed, keeping the cutter sharp, and avoiding excessive pressure. Always check the tool holder for tightness before starting.

Common mistakes to avoid

- Not adjusting depth correctly

- Using a dull cutter

- Inefficient movement

- Forgetting to clean the workspace

Maintenance and Care of Fly Cutters

Best practices for cleaning and maintaining fly cutters.. How to sharpen and replace cutting edges for optimal performance..Taking care of your fly cutter is like giving your favorite toy some TLC. First, clean it regularly with a soft cloth to remove any dust or shavings. This keeps it shiny and working well! Every so often, check the cutting edges. If they look dull, it’s time to sharpen them. You can use a sharpening stone or a grinder. And remember, if it’s too worn out, replace it for the best results. Here’s a quick maintenance table:

| Action | Frequency |

|---|---|

| Clean Fly Cutter | After Each Use |

| Sharpen Edges | As Needed |

| Replace Cutting Edges | When Worn |

With good care, your fly cutter will be ready to slice like a pro! Just treat it right, and it will reward you with perfect cuts every time.

Safety Considerations When Using Fly Cutters

Essential safety gear and precautions to take.. Potential hazards and how to mitigate them during operation..Before grabbing a fly cutter, slip on some safety gear! Wear goggles to protect your eyes, and don’t forget earplugs to block out the noisy machinery. A hard hat can save your head from unwanted bumps. Remember, the spinning cutter is like a flying frisbee—only not as fun!

Always check your machine for loose parts. Loose screws can cause major headaches, and not the fun party kind! Keep your hands clear of the tool’s path. Few things are worse than a surprise haircut when you’re just trying to mill something!

| Safety Gear | Purpose |

|---|---|

| Goggles | Protects eyes from debris |

| Earplugs | Shields ears from loud noise |

| Hard Hat | Prevents head injuries |

Lastly, keep the workspace tidy. A clean area helps avoid slips and trips! By following these simple tips, you can enjoy using a fly cutter without any major mishaps. Remember, safety first, fun second!

Troubleshooting Common Issues

Identifying and solving common problems encountered when using fly cutters.. Tips for achieving a better finish and reducing chatter during milling..Many issues can arise while using a fly cutter. Identifying these problems early can save time. Common problems include uneven cuts and loud noises, which often mean the cutter is not sharp. Check the tool regularly. To improve finish and reduce chatter, try these tips:

- Use a sharp cutter.

- Adjust the spindle speed.

- Keep the work piece secure.

- Use a steady feed rate.

Following these steps can help achieve smooth and accurate results.

What are common problems when using a fly cutter?

Common problems include uneven surfaces, excessive noise, and dull cutters. Checking for sharpness and adjusting settings can usually solve these issues.

Conclusion

In conclusion, using a fly cutter in milling can give you smooth, flat surfaces. Remember to set the right speed and depth. Always secure your workpiece properly. Safety is key, so wear protective gear. Now, go practice your skills with a fly cutter! For more tips, check out beginner guides or videos online. Happy milling!FAQs

What Is A Fly Cutter, And How Does It Differ From Other Milling Tools?A fly cutter is a special tool used in milling machines. It has a long arm with one cutting edge that spins around. When it moves, it cuts flat surfaces on metal or wood. Unlike other milling tools that have many cutting edges, a fly cutter has only one. This makes it good for smooth and big flat areas.

What Are The Steps To Set Up A Fly Cutter On A Milling Machine?To set up a fly cutter on a milling machine, first, you need to turn off the machine. Next, you will take off any tools that are already on the spindle. Then, you can attach the fly cutter by screwing it onto the spindle firmly. After that, you should adjust the height of the cutter to the right level. Finally, turn on the machine and check if it’s working smoothly.

What Materials Are Best Suited For Machining With A Fly Cutter?Fly cutters work best on soft metals and plastics. You can use them on aluminum and brass easily. They also cut wood and some types of softer steel. These materials are easier to shape and smooth out.

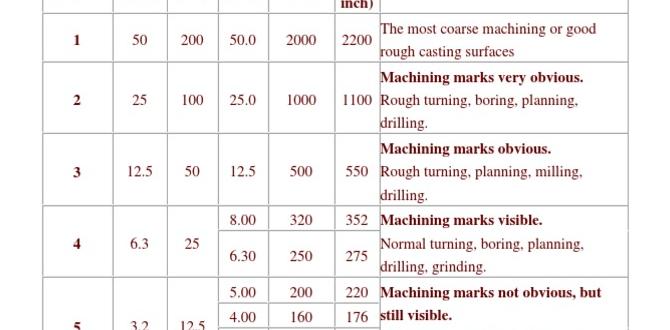

How Do You Determine The Optimal Cutting Speed And Feed Rate When Using A Fly Cutter?To find the best cutting speed and feed rate for a fly cutter, you can start by checking the material you are cutting. Different materials need different speeds. You can use a chart or calculator to guide you. Then, try out a few speeds and feed rates, and see which one cuts the best. Always remember to stay safe and use protective gear!

What Safety Precautions Should Be Taken When Operating A Fly Cutter During Milling?When using a fly cutter, we should always wear safety glasses to protect our eyes. It’s important to keep our hair tied back and wear tight clothes, so nothing gets caught. Make sure your hands are clear of the spinning tool before turning it on. Always check the machine is in good shape and that tools are secure. Last, we should never rush; take your time to work safely.