Have you ever wondered how a simple piece of metal can be shaped into something amazing? Using a metal lathe is one of the best ways to create precise shapes. But, if you’ve tried it, you might have noticed the gear train. It plays a big role in how the lathe works.

Imagine you want to turn a block of metal into a perfect cylinder. You need the right tools and knowledge for that task. The gear train helps you adjust the lathe’s speed and power. This makes your job easier and more fun.

Here is a fun fact: Did you know that different gears can change how fast the lathe spins? This means you can create different shapes by simply changing the gear setup. It’s like having a secret superpower for making cool metal projects!

In this article, we’ll explore how to use the metal lathe gear train effectively. You will learn the basics that can help you become a better metalworker. Are you ready to dive in?

How To Use Metal Lathe Gear Train Effectively For Precision

How to Use Metal Lathe Gear Train

Using a metal lathe gear train can seem tricky, but it’s essential for smooth operation. This setup changes speeds and torque. Imagine trying to ride a bike uphill; you need the right gear to make it easier. To start, select gears based on your desired speed. Adjustments help you control the cut’s precision. Learn the setup techniques, and you can create amazing projects. Did you know a well-adjusted gear train can double your work efficiency? It’s true!Understanding the Metal Lathe Gear Train

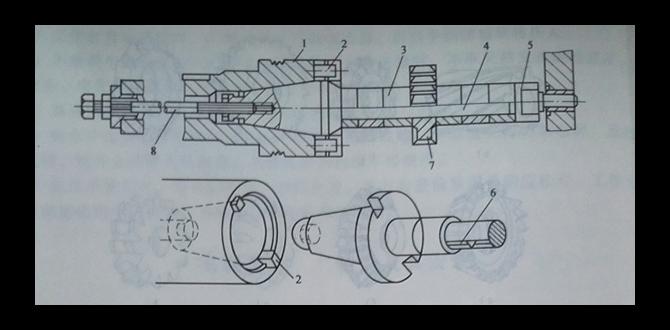

Definition and components of a gear train. Importance of gear trains in metal lathes.A gear train is a system of gears working together. Each gear connects and helps to transfer power. A metal lathe uses gear trains to adjust speed and torque. This makes it easier to cut metal shapes.

Why are gear trains important in metal lathes?

- They control the machine’s speed.

- They increase cutting power.

- They provide smooth operation.

Using a gear train makes metal lathes more efficient and accurate. Understanding this system helps you make better parts!

What is a gear train?

A gear train is a group of gears designed to transfer force and motion between different parts of a machine.

Setting Up Your Metal Lathe Gear Train

Stepbystep guide to assembling the gear train. Common mistakes to avoid during setup.First, gather all your gear train parts. Grab a cup of coffee too—it helps! Then, follow these easy steps to assemble: start with the main spindle, then attach the gears in the right order. Remember, matching the sizes is key! Don’t forget to tighten those screws or your gears will dance like they’re at a disco.

Here’s a table to guide you:

| Step | Action |

|---|---|

| 1 | Position the main spindle |

| 2 | Attach the first gear |

| 3 | Match sizes of subsequent gears |

| 4 | Tighten all screws |

Avoid common mistakes like mismatching gear sizes or forgetting to secure screws. These blunders can lead to messy results, or worse, a gear train meltdown! Remember: a little planning goes a long way.

Adjusting Gear Ratios for Precision Work

Explanation of gear ratios and their impact on machining. How to calculate and adjust gear ratios effectively.Gear ratios are like magic numbers that help you control how fast and precise your machine works. A higher gear ratio means more torque, giving you a powerful cut. Lower ratios let you spin faster, perfect for smooth finishes. To adjust these ratios, start by checking your gear setup. You can change the gears or reposition them to get the right mix. Here’s a quick look at different ratios:

| Gear Combination | Speed (RPM) | Torque |

|---|---|---|

| 1:1 | 1000 | 50 Nm |

| 2:1 | 500 | 100 Nm |

| 4:1 | 250 | 200 Nm |

Testing different setups can lead to surprising results! Remember, the best gear ratio might just be one adjustment away!

Maintenance Tips for Gear Trains

Routine maintenance procedures for longevity. Signs of wear and when to replace components.Taking care of your gear train is like brushing your teeth; skip it, and things get messy! Routine checks help your lathe last longer. Look for signs like unusual noises or excessive wear. If your gears look worse than a spaghetti monster, it’s time for a replacement! Here’s a quick guide:

| Signs of Wear | Action Needed |

|---|---|

| Unusual noises | Inspect components |

| Excessive play | Replace worn parts |

| Visible damage | Get new gears |

Keep your gear train happy, and it will keep you spinning in the right direction!

Common Applications of Gear Trains in Machining

Types of projects that benefit from different gear setups. Examples of industryspecific applications.Gear trains play a big role in making machines work better. They help change the speed and strength of rotating parts. For instance, in the automotive industry, you can find them in gearboxes, which help cars zoom smoothly down the road. In the world of manufacturing, gear trains are vital for cutting metal and shaping materials precisely. Some projects that benefit from different gear setups include screw machines, lathes, and milling machines. These setups can help save time and make tasks easier. Here’s a quick look:

| Project Type | Gear Train Use |

|---|---|

| Screw Machines | Quick, repetitive tasks |

| Lathes | Smoothly shape materials |

| Milling Machines | Precise cutting |

So, whether you’re making cars or toys, the right gear train can turn your work from “meh” to “wow!”

Troubleshooting Gear Train Issues

Common problems and their solutions. Tips for diagnosing issues quickly and efficiently.Gear train problems can be tricky. Here are some common issues and solutions:

- Slipping gears: Check for wear and ensure gears are properly lubed.

- Noisy operation: Inspect for loose parts or debris in the gears.

- Poor speed control: Look for damaged belts or incorrect gear settings.

To find issues faster:

- Listen for unusual sounds.

- Watch for vibrations in the machine.

- Feel for any changes in machine movement.

What are common problems with gear trains?

Common problems include slipping gears, noise, and speed control issues.

Advanced Techniques Using Gear Trains

Techniques for skilled machinists to enhance productivity. Integrating gear train usage with other machining technologies.Using advanced techniques with gear trains benefits skilled machinists greatly. These techniques can boost productivity and precision. For example, combining gear trains with CNC machines improves workflow. It also saves time. Here are some key methods:

- Integrate gear ratios for more control.

- Utilize multiple gear trains for complex tasks.

- Adjust speed settings for different materials.

These approaches enhance machine performance and make challenging projects easier. The right techniques simplify your work while improving results.

How can gear trains improve machining skills?

Using gear trains helps *skilled machinists* achieve better results. They allow for precise movements and can increase the speed of production. This means you can create more parts in less time.

Conclusion

In summary, using a metal lathe gear train helps you control speed and torque. Start by understanding the parts and their functions. Adjust gears carefully to match your project. Practice makes perfect, so take your time. For more tips, check out beginner guides or videos. Dive in and enjoy creating with your lathe!FAQs

What Is The Purpose Of The Gear Train In A Metal Lathe And How Does It Affect Spindle Speed?The gear train in a metal lathe helps change the speed of the spindle, which is the part that holds and spins the metal. By using different gears, you can make the spindle spin faster or slower. This is important because different tasks need different speeds. So, the gear train lets us create the right speed for the job we are doing.

How Can I Adjust The Gear Train On A Metal Lathe For Different Thread Pitches?To adjust the gear train on a metal lathe for different thread pitches, first, find the gear settings in your lathe’s manual. Next, change the gears to match the thread pitch you want. This usually involves swapping out gears with different sizes. Make sure all the gears fit tightly and turn freely. Lastly, test your lathe to see if it makes the right threads.

What Are The Common Configurations Of Gear Trains Used In Metal Lathes, And How Do They Differ?Metal lathes use gear trains to help turn and shape metal. The most common types are simple gear trains, compound gear trains, and epicyclic gear trains. Simple gear trains have just a few gears working together. Compound gear trains have more gears and can change speeds better. Epicyclic gear trains allow gears to move around each other, giving you even more speed options! Each type helps us make different shapes and sizes of metal pieces.

How Do I Properly Maintain And Lubricate The Gear Train Components Of My Metal Lathe?To take care of your metal lathe’s gear train, start by cleaning it regularly. Use a soft cloth to wipe away dirt and old grease. Next, apply a light oil or lubricant to the gears. Be careful not to use too much; a little goes a long way! Finally, check the gears often to make sure they are in good shape.

What Safety Precautions Should I Take When Working With The Gear Train On A Metal Lathe?When working with the gear train on a metal lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and remove any loose clothing or jewelry. Make sure your hands are dry and clean to avoid slipping. Before starting the machine, check that everything is in place and not loose. Finally, stay focused and do not distract others while they are using the lathe.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of The Gear Train In A Metal Lathe And How Does It Affect Spindle Speed? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The gear train in a metal lathe helps change the speed of the spindle, which is the part that holds and spins the metal. By using different gears, you can make the spindle spin faster or slower. This is important because different tasks need different speeds. So, the gear train lets us create the right speed for the job we are doing.”}},{“@type”: “Question”,”name”: “How Can I Adjust The Gear Train On A Metal Lathe For Different Thread Pitches? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the gear train on a metal lathe for different thread pitches, first, find the gear settings in your lathe’s manual. Next, change the gears to match the thread pitch you want. This usually involves swapping out gears with different sizes. Make sure all the gears fit tightly and turn freely. Lastly, test your lathe to see if it makes the right threads.”}},{“@type”: “Question”,”name”: “What Are The Common Configurations Of Gear Trains Used In Metal Lathes, And How Do They Differ? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use gear trains to help turn and shape metal. The most common types are simple gear trains, compound gear trains, and epicyclic gear trains. Simple gear trains have just a few gears working together. Compound gear trains have more gears and can change speeds better. Epicyclic gear trains allow gears to move around each other, giving you even more speed options! Each type helps us make different shapes and sizes of metal pieces.”}},{“@type”: “Question”,”name”: “How Do I Properly Maintain And Lubricate The Gear Train Components Of My Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To take care of your metal lathe’s gear train, start by cleaning it regularly. Use a soft cloth to wipe away dirt and old grease. Next, apply a light oil or lubricant to the gears. Be careful not to use too much; a little goes a long way! Finally, check the gears often to make sure they are in good shape.”}},{“@type”: “Question”,”name”: “What Safety Precautions Should I Take When Working With The Gear Train On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When working with the gear train on a metal lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and remove any loose clothing or jewelry. Make sure your hands are dry and clean to avoid slipping. Before starting the machine, check that everything is in place and not loose. Finally, stay focused and do not distract others while they are using the lathe.”}}]}