Imagine you’re in a workshop, surrounded by cool tools. You see a metal lathe, quiet and ready to work. Have you ever wondered how to use metal lathe power feed? It can make your projects easier and more precise. Instead of cranking the handle all the time, power feed does the work for you. Isn’t that neat?

Many people shy away from using a lathe because they think it’s too difficult. But once you understand the basics, you’ll see it’s quite simple. Learning how to use the metal lathe power feed can open up a world of possibilities.

In this article, we’ll explore how to make the most of this powerful feature. From simple setups to important safety tips, you’ll be ready to take on new projects. Are you excited to dive in? Let’s get started!

How To Use Metal Lathe Power Feed Effectively And Safely

Understanding Metal Lathe Power Feed

Using a metal lathe power feed can make your projects easier and faster. But how do you actually use it? First, you need to set up the machine properly. Ensure the feed rate is correctly adjusted for your material. When you’re ready, engage the power feed lever. Did you know that a powered feed can help produce smoother finishes? This means less time spent sanding later! With this handy tool, even beginners can create professional-quality parts.Understanding Metal Lathes

Definition and purpose of a metal lathe. Key components of a metal lathe.A metal lathe is a machine that shapes metal into different forms. It spins the metal while a cutting tool carves it into precise shapes. Metal lathes are used in many industries, like making tools and parts for machines. They help create everything from simple rods to complex gears.

Key parts of a metal lathe include:

- Bed: The base that holds everything together.

- Chuck: A clamp that holds the metal piece.

- Tool Post: Where the cutting tool is attached.

- Tailstock: Supports the metal and helps with drilling.

With these parts, you can make amazing things from metal!

What is a metal lathe used for?

A metal lathe is used for shaping and cutting metal into various objects and parts. It plays a key role in many manufacturing processes.

Benefits of Using Power Feed

Advantages over manual feeding. Improved precision and consistency in machining.Using a power feed on a metal lathe has many benefits. It is easier than feeding manually. You don’t need to push the material by hand. This saves time and energy. Also, power feed makes your work more precise. You get even cuts every time. This helps in making parts that fit perfectly. Power feed can also reduce mistakes and improve the quality of your projects. It’s a smart choice for anyone using a metal lathe.

What are the main advantages of power feed?

The main advantages of power feed include:

- Greater control over the machining process.

- Reduced operator fatigue.

- Consistent results every time.

- Less chance of damaging materials.

Setting Up Your Metal Lathe for Power Feed

Necessary tools and equipment for setup. Stepbystep guide for connecting power feed system.To set up your metal lathe for power feed, you need several tools. First, gather a wrench, screwdriver, and a power feed kit. You’ll also need safety goggles to keep your eyes protected. Follow these simple steps to connect the system:

- 1. Turn off the lathe and unplug it.

- 2. Remove the existing handle from the carriage.

- 3. Attach the power feed motor securely.

- 4. Connect the wiring according to the instructions.

- 5. Finally, plug in the lathe and test the power feed.

Setting up might seem tricky at first, but once you get the hang of it, it becomes a fun project!

What tools are needed for metal lathe power feed setup?

Essential tools include a wrench, screwdriver, safety goggles, and a power feed kit.

Operating the Power Feed

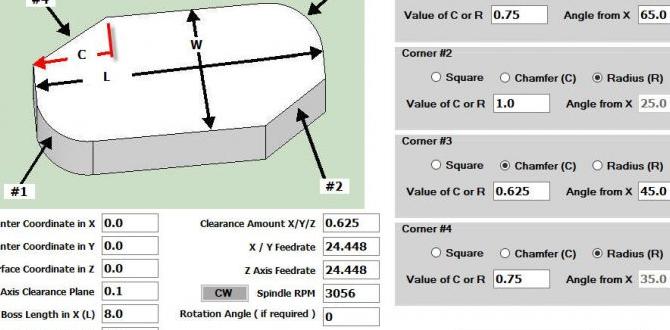

Detailed instructions on how to engage the power feed. Tips for adjusting speed and feed rate.To start using the power feed on your metal lathe, find the switch—it’s usually labeled. Flip it on, and listen for the reassuring hum. Next, adjust the feed rate. Don’t be shy! It’s like setting the speed for a racecar; too fast and you’ll fly off the track! Play with the speed knob until it feels just right. Remember, slow and steady wins the race. Here’s a quick guide:

| Feed Rate | Speed |

|---|---|

| Low | Slow |

| Medium | Moderate |

| High | Fast |

Always keep your hands safely away from the cutting area. Your fingers are not meant to be lathe snacks! Adjusting settings while the lathe is running is like trying to change a tire on a speeding car. It’s best left for when the machine is stopped.

Common Challenges and Troubleshooting

Identifying frequent issues with power feed. Solutions and maintenance tips.Many people face problems while using power feed on a metal lathe. Some common issues include slow movement and stuck gears. If you notice these, check the power supply and clean the feed mechanism. Regular maintenance helps, too! Here are a few tips:

- Keep the machine clean.

- Check oil levels often.

- Run the lathe at proper speed.

These steps can help avoid headaches and keep your machine running smoothly.

What can cause power feed problems?

Common causes include low oil levels, dirty parts, or electrical issues. Regular checks can help prevent these problems.

How can I maintain my metal lathe?

- Clean regularly to remove dust and debris.

- Lubricate moving parts to ensure smooth function.

- Inspect for wear and tear frequently.

Safety Precautions while Using Power Feed

Essential safety gear and practices. Potential hazards and how to mitigate them.Using a power feed can be fun and safe if you follow some guidelines. First, wear protective gear like safety goggles, gloves, and ear protection. These help shield your eyes and ears from harmful noise and flying debris. Be aware of potential hazards, such as moving parts. Always keep your hands and loose clothing away from the machine. A tidy workspace can also prevent accidents.

- Wear safety goggles to protect your eyes.

- Use gloves to safeguard your hands.

- Keep hair tied back and clothes fitted.

These simple practices can keep you safe while working with a metal lathe.

What are the common safety hazards with power feed?

Common hazards include moving parts, flying debris, and noise. It’s important to stay alert and follow safety rules to avoid injuries.

Advanced Techniques for Experienced Users

Tips for optimizing power feed for complex machining. Customizing power feed settings for different materials.For expert users, fine-tuning your power feed can transform your machining projects. Start with these tips:

- Match feed speed to material type. Softer metals need slower speeds for better results.

- Adjust depth of cut based on workpiece. Thicker pieces may need slower feeds.

- Use consistent speeds. This practice leads to smoother finishes and reduces wear.

Each material may require a different approach. Testing settings helps you find the best configuration for your projects. Remember, patience and practice make perfect.

What are some tips for optimizing the power feed?

Use the right speed based on the material. Adjust settings for depth and consistency. These adjustments lead to better machining outcomes.

Conclusion

In summary, using a metal lathe power feed makes your work easier and more efficient. Remember to adjust the feed rate and keep your tools sharp. Practice with different materials to improve your skills. Now, you’re ready to try it out! For more tips, check out guides or videos that show power feed techniques. Happy machining!FAQs

Sure! Here Are Five Related Questions On How To Use A Metal Lathe Power Feed:Sure! Here are some tips for using a metal lathe with power feed. First, make sure you understand the machine’s controls. Then, set the right speed for your project. You can start the power feed by pressing a button or a switch. Always keep your hands clear of the moving parts to stay safe!

Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.

What Is The Purpose Of The Power Feed Feature On A Metal Lathe?The power feed feature on a metal lathe helps make spinning metal easier. It moves the tool automatically, so you don’t have to push it by hand. This saves time and makes cuts more even. You can focus on your work without getting tired from moving the tool yourself. It’s like having a helpful robot!

How Do You Set The Correct Feed Rate When Using Power Feed On A Metal Lathe?To set the correct feed rate on a metal lathe, you start by checking the task you’re doing. Look at the material you are cutting and the size of your tool. You want the feed rate to be fast enough to cut but slow enough to keep the tool safe. It helps to test different speeds on scrap pieces to find what works best. Always adjust based on how the metal feels as you cut!

What Are The Precautions To Take When Operating The Power Feed On A Metal Lathe?When using the power feed on a metal lathe, always keep your hands away from moving parts. Make sure to wear safety glasses to protect your eyes. Check that the lathe is in good condition before starting. Pay attention to what you’re doing and don’t get distracted. If you feel unsure, ask an adult for help.

How Do You Switch Between Manual And Power Feed Modes On A Metal Lathe?To switch between manual and power feed modes on a metal lathe, first find the control switch. This switch usually has two settings: one for manual and one for power feed. If you want to use power feed, move the switch to that setting. For manual mode, move the switch back. Always make sure the lathe is stopped before switching modes.

What Common Issues Might Arise When Using Power Feed On A Metal Lathe, And How Can They Be Resolved?When you use power feed on a metal lathe, you might face a few issues. Sometimes, the machine can move too fast or too slow. If this happens, you can adjust the speed settings to fix it. Another problem is the tool getting stuck or breaking. You can prevent this by checking the tool and making sure it is sharp and secure. Regular cleaning helps keep everything running smoothly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On How To Use A Metal Lathe Power Feed:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some tips for using a metal lathe with power feed. First, make sure you understand the machine’s controls. Then, set the right speed for your project. You can start the power feed by pressing a button or a switch. Always keep your hands clear of the moving parts to stay safe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Power Feed Feature On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The power feed feature on a metal lathe helps make spinning metal easier. It moves the tool automatically, so you don’t have to push it by hand. This saves time and makes cuts more even. You can focus on your work without getting tired from moving the tool yourself. It’s like having a helpful robot!”}},{“@type”: “Question”,”name”: “How Do You Set The Correct Feed Rate When Using Power Feed On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set the correct feed rate on a metal lathe, you start by checking the task you’re doing. Look at the material you are cutting and the size of your tool. You want the feed rate to be fast enough to cut but slow enough to keep the tool safe. It helps to test different speeds on scrap pieces to find what works best. Always adjust based on how the metal feels as you cut!”}},{“@type”: “Question”,”name”: “What Are The Precautions To Take When Operating The Power Feed On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the power feed on a metal lathe, always keep your hands away from moving parts. Make sure to wear safety glasses to protect your eyes. Check that the lathe is in good condition before starting. Pay attention to what you’re doing and don’t get distracted. If you feel unsure, ask an adult for help.”}},{“@type”: “Question”,”name”: “How Do You Switch Between Manual And Power Feed Modes On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To switch between manual and power feed modes on a metal lathe, first find the control switch. This switch usually has two settings: one for manual and one for power feed. If you want to use power feed, move the switch to that setting. For manual mode, move the switch back. Always make sure the lathe is stopped before switching modes.”}},{“@type”: “Question”,”name”: “What Common Issues Might Arise When Using Power Feed On A Metal Lathe, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use power feed on a metal lathe, you might face a few issues. Sometimes, the machine can move too fast or too slow. If this happens, you can adjust the speed settings to fix it. Another problem is the tool getting stuck or breaking. You can prevent this by checking the tool and making sure it is sharp and secure. Regular cleaning helps keep everything running smoothly.”}}]}