Have you ever wondered how to choose the right tool for milling? The world of cutting tools can be confusing. Among them, indexable milling cutters and solid carbide cutters are popular choices. Each has its strengths and weaknesses.

Imagine you are in a workshop. You have a big project ahead, and you need the best cutter. Would you pick an indexable milling cutter or go for a solid carbide one? This decision can affect your project’s success!

Did you know that indexable milling cutters can save you time and money? They allow you to change inserts easily. This means less downtime. On the other hand, solid carbide tools are often more durable and can handle tough materials well. Which one do you think would help you work smarter?

In this article, we will explore the differences between these two tools. You will learn their unique advantages and best uses. Let’s dive into the fascinating world of milling cutters!

Indexable Milling Cutter Vs Solid Carbide: An In-Depth Comparison

Indexable Milling Cutter vs. Solid Carbide

When choosing between an indexable milling cutter and solid carbide, understanding their differences helps make better choices. Indexable cutters have replaceable inserts, offering flexibility and cost savings. They work well for various materials. On the other hand, solid carbide tools provide better durability and precision for detailed work. Did you know that solid carbide can handle high speeds? This makes it a favorite among serious machinists. Choosing the right tool can greatly impact your project’s success!Understanding Milling Cutters

Definition and purpose of milling cutters in machining.. Various types of milling cutters and their applications..Milling cutters are special tools used in machining to shape materials like metal or wood. Their main purpose is to remove material to create the desired shape, kind of like carving a pumpkin but without the mess! There are many types of milling cutters, each designed for specific jobs. For example, the end mill is great for doing detailed work, while the slab mill can tackle larger surfaces.

| Type of Cutter | Applications |

|---|---|

| End Mill | Detailed carving and shaping |

| Slab Mill | Flattening large surfaces |

| Face Mill | High-speed processing of flat surfaces |

Choosing the right cutter is like picking the right ice cream flavor—each one has its unique taste and purpose! In machining, this ensures precision and efficiency, helping create everything from tiny parts to giant structures.

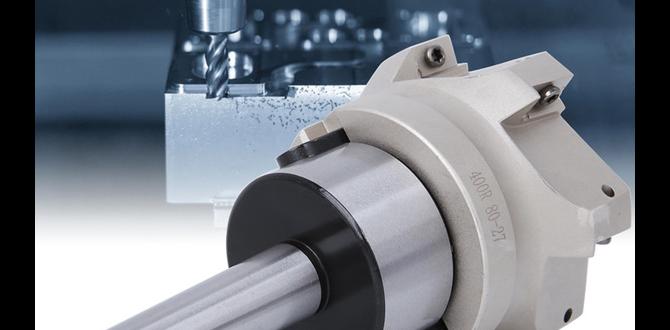

What is an Indexable Milling Cutter?

Explanation of indexable milling cutters and their design features.. Advantages of using indexable milling cutters in manufacturing processes..An indexable milling cutter is a tool used in manufacturing. It has replaceable cutting edges that make it easy to use. This design means you can change just the edges, not the whole tool. This saves time and money. Here are some key features:

- Interchangeable inserts for easy replacement.

- Durable materials that last longer.

- Versatile designs for different tasks.

These cutters have many advantages:

- Improved productivity.

- Cost-effective due to long-lasting edges.

- Better surface finish on materials.

Using indexable milling cutters helps manufacturers make goods more quickly and save money!

What are the benefits of indexable milling cutters?

Indexable milling cutters offer faster production and cost savings. Their long-lasting inserts mean fewer tool changes. This allows factories to run smoothly and meet deadlines better.

Performance Comparison: Indexable vs. Solid Carbide

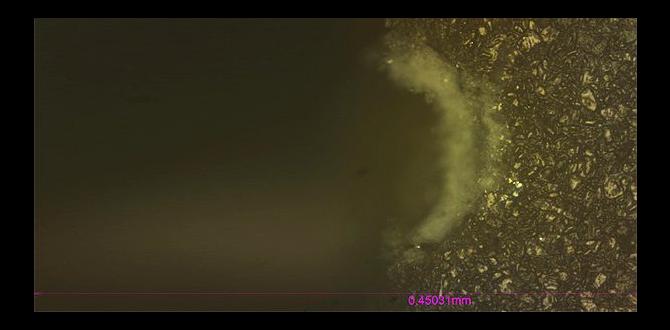

Cutting efficiency and durability: A sidebyside comparison.. Factors affecting performance such as material removal rates and tool life..When comparing indexable milling cutters and solid carbide tools, cutting efficiency and durability are key players. Indexable cutters can be swapped out easily, keeping them sharp without breaking the bank. Solid carbide tools, on the other hand, are like the superheroes of machining, boasting longer tool life but at a higher price. Performance also depends on factors like material removal rates. For instance, indexables excel in softer materials, while solid carbide shines in hard stuff—guess they have their preferences!

| Tool Type | Cutting Efficiency | Durability |

|---|---|---|

| Indexable Milling Cutter | Moderate | Good, replaceable inserts |

| Solid Carbide | High | Excellent, long-lasting |

So, if you want a quick, sharp solution, indexable might be your best friend. But if you’re after long-lasting quality, solid carbide could save your day—and your wallet in the long run!

Cost Analysis: Indexable Milling Cutter vs Solid Carbide

Initial investment costs and longterm economic benefits.. Costperpart calculations and value considerations..Choosing between an indexable milling cutter and solid carbide is like picking between a cookie monster and a cookie. Both have their strengths and costs. Initially, indexable cutters might seem pricier, but they can be re-sharpened and reused, saving you money over time. Meanwhile, solid carbide tools are a lovely one-time investment but might go dull faster than a boring lecture.

| Type | Initial Cost | Long-Term Savings |

|---|---|---|

| Indexable Milling Cutter | Higher | Better due to reusability |

| Solid Carbide | Lower | Less savings over time |

So, when you crunch the numbers with cost-per-part calculations, indexable tools may be the wise shopping choice in the long haul! Think of it this way, would you rather have a never-ending cookie jar or an empty box?

Application Suitability

Ideal scenarios for using indexable milling cutters.. Use cases where solid carbide cutters outshine indexable options..Indexable milling cutters are best for big jobs. They can easily change inserts for different tasks. This saves time and money. They work great in high-speed operations and long-run projects. Solid carbide cutters shine in precision tasks. They give smooth finishes and sharp edges. They are perfect for small pieces where details matter.

- **Indexable milling cutters:** Ideal for large-scale and varied tasks.

- **Solid carbide cutters:** Best for detailed and delicate work.

When should I use indexable milling cutters?

Use indexable milling cutters for larger jobs or when you need to change tools quickly.

What makes solid carbide cutters unique?

Solid carbide cutters are strong and provide better finishes for small, detailed pieces.

Maintenance and Tool Life

Maintenance requirements for indexable milling cutters versus solid carbide.. Tips for maximizing tool life and performance in each category..Proper care helps tools last longer. Indexable milling cutters need regular checks. Make sure the inserts are tight. Clean any chips stuck in the tool. Solid carbide cutters also need care. Keep them sharp and avoid hard materials. Here are tips to boost tool life:

- Clean tools after each use.

- Store in a dry place.

- Use appropriate speeds for each material.

Good maintenance leads to better performance and saves money!

How do I maximize tool life?

For indexable milling cutters, control cutting speed. For solid carbide, don’t apply too much pressure. Both tools need proper storage.

Market Trends and Innovations

Current trends in milling cutter technology and design.. Future possibilities and advancements in indexable and solid carbide milling tools..Milling cutter technology is changing fast. Today, manufacturers focus on making tools lighter and stronger. Indexable milling cutters are becoming popular because they can be used many times. Solid carbide tools are also improving. They are getting better at cutting harder materials. In the future, we may see tools that can change their shape. This would make machining easier and faster.

What are current trends in milling cutter technology?

The main trends include:

- Lightweight designs for better control.

- Increased toughness for longer life.

- Smart technology for monitoring performance.

What advancements are expected in the future?

Innovations may include:

- Shape-shifting tools for various tasks.

- Advanced coatings to reduce wear.

- Eco-friendly materials for a sustainable future.

Conclusion

In summary, indexable milling cutters and solid carbide tools each have their advantages. Indexable tools are cost-effective and versatile, while solid carbide offers precision and durability. Choose based on your specific needs and budget. To learn more about these tools, explore additional resources or ask an expert. Understanding the differences will help you make informed choices in your projects!FAQs

What Are The Key Differences In Performance Between Indexable Milling Cutters And Solid Carbide End Mills In Various Machining Applications?Indexable milling cutters have changeable tips, so you can swap them when they wear out. This saves you money and time. Solid carbide end mills are stronger and can give a smoother finish on the work. However, they can break easier than indexable cutters in tough jobs. So, for long jobs, indexable cutters are great, but for fine details, solid carbide works better.

How Do The Costs Of Indexable Milling Cutters Compare To Solid Carbide Tools, Considering Factors Like Tool Life And Productivity?Indexable milling cutters usually cost less than solid carbide tools. You can change the cutting tip on indexable tools, which saves money. They often last longer, so you don’t have to buy new ones as often. This means they can help you make more parts quickly. Overall, you might save money and time with indexable cutters.

In What Scenarios Would It Be More Beneficial To Use Indexable Milling Cutters Over Solid Carbide Tools?Indexable milling cutters are better when you need to cut a lot of metal. They let you change just the cutting part instead of the whole tool. This saves money and time because you don’t need to buy new tools all the time. If the tool gets dull, you can just flip or replace the cutting edge. This makes them great for big jobs or when you need to cut different shapes.

How Does The Chip Evacuation And Cooling Properties Of Indexable Milling Cutters Compare To Solid Carbide Options During High-Speed Machining?Indexable milling cutters and solid carbide cutters help us cut metal in different ways. Indexable cutters have special edges that you can change. They usually handle chips better, meaning they get rid of leftover pieces faster. They also cool down more easily, so they don’t overheat as much. Solid carbide options can get hot and may not clear chips as well during high-speed machining.

What Are The Advantages And Disadvantages Of Replacing Solid Carbide Tools With Indexable Milling Cutters For High-Volume Production Environments?Using indexable milling cutters instead of solid carbide tools has some good and bad points. One advantage is that we can change just the cutting part when it wears out, which saves money. They are also easier to use for lots of pieces, making our work faster. However, they can be less precise, leading to mistakes. Another downside is that they might not last as long as solid carbide tools.