Imagine creating a tiny part for a model airplane. You need precision, right? That’s where the kit metal lathe comes in. One important part of this machine is the compound rest. It helps you position your workpiece exactly where you want it.

The compound rest lets you make precise cuts at different angles. It can turn simple metal blocks into complex shapes. Have you ever wondered how something like a gear is made? Usually, a metal lathe and its compound rest do the trick!

Learning to use a kit metal lathe can be exciting. Picture yourself making custom parts for your projects. This tool unlocks creativity and skill. With practice, anyone can become a metalworking expert.

In this article, we’ll explore the compound rest in detail. You’ll discover its features and importance. Let’s dive into the wonderful world of metalworking!

Essential Guide To The Kit Metal Lathe Compound Rest Setup

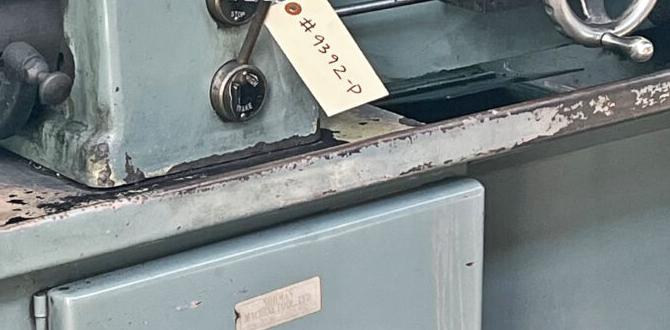

Understanding the Kit Metal Lathe Compound Rest

The kit metal lathe compound rest is a vital part of a lathe. It helps you adjust and control the tool’s position. This makes it easier to shape materials accurately. Did you know that without a compound rest, turning metal could be very tricky? Many users appreciate how it improves their woodworking or metalworking projects. Whether you’re a beginner or an expert, understanding how this piece works can enhance your skills in crafting beautiful items.Understanding the Compound Rest

Definition and purpose of the compound rest in metal lathes. Key components and their functions in enhancing machining accuracy.The compound rest is an important part of a metal lathe. It helps hold the cutting tool in place. This makes it easier to cut metal accurately. The main pieces include the slide, the clamping lever, and the adjusting screws. These parts work together to fine-tune the tool’s position and angle. This control improves machining accuracy, allowing for better results in metalworking.

What are the key components of the compound rest?

- Slide: Moves the tool in various directions.

- Clamping Lever: Secures the tool in place.

- Adjusting Screws: Fine-tune the tool’s angle for precision.

This setup makes the compound rest essential for skilled metalworking. Without it, achieving precise cuts would be a lot harder. It empowers the lathe operator to create detailed and accurate pieces. Isn’t that fascinating?

How to Adjust the Compound Rest

Stepbystep guide on leveling and aligning the compound rest. Common adjustments for various machining operations (e.g., angles, heights).Adjusting the compound rest is like tuning a guitar; it needs to be just right! Start by leveling it. Use a small level and slide it on the surface. If it’s off, adjust the screws underneath until it’s perfectly flat. Next, align it for your task. For angles, you can rotate the rest and check with a protractor. Don’t forget height too! It’s key for smooth cutting. If you’re boring a hole, keep it low; for cutting threads, higher is better. Easy-peasy, right? Now, let’s look at a quick guide:

| Operation | Common Adjustment |

|---|---|

| Turning | Level and align to flat |

| Boring | Lower position preferred |

| Thread Cutting | Raise for better reach |

Remember, practice makes perfect! Adjusting can be tricky, but soon you’ll be a pro instead of a “lathe loser!”

Materials and Construction of Compound Rests

Common materials used in manufacturing compound rests. Impact of material quality on durability and performance.Compound rests are made from a few common materials. Cast iron is popular because it is strong and absorbs vibrations well. Aluminum is lighter and easier to work with. Steel provides great strength and durability. The quality of these materials affects the rest’s life and performance. High-quality materials help a compound rest last longer and perform better.

What materials are usually used for compound rests?

The most common materials are cast iron, aluminum, and steel. Each has its own benefits and drawbacks, affecting durability and performance.

- Cast Iron: Strong but heavy.

- Aluminum: Lightweight and easy to handle.

- Steel: Very strong and sturdy.

Maintenance Tips for Longevity

Best practices for cleaning and lubrication. Signs of wear and tear to watch for and how to address them.Keeping your kit metal lathe compound rest in top shape is crucial for its performance. To start, clean it regularly with a soft cloth to remove dust and debris. Make sure to use a good lubricant to keep parts moving smoothly. Watch for signs of wear, like unusual noises or rough movements. If you notice something odd, address it quickly to avoid bigger problems. Remember, a happy lathe is a productive lathe!

| Maintenance Task | Frequency |

|---|---|

| Cleaning | Weekly |

| Lubrication | Bi-Weekly |

| Wear Check | Monthly |

Upgrades and Modifications

Popular aftermarket modifications for enhanced functionality. Compatibility considerations when upgrading the compound rest.Upgrading your kit metal lathe compound rest can boost your project results. Many enthusiasts add features like better clamping systems or digital readouts for accuracy. These upgrades make your work easier and more precise. However, always check for compatibility. Ensure new parts fit your lathe model. That way, you avoid frustrating mix-ups. Popular modifications include:

- Improved gears for smoother operation.

- Sturdier bases for extra stability.

- Enhanced knobs for easier adjustments.

What are common upgrades for a lathe compound rest?

Common upgrades include digital readouts, improved clamping systems, and sturdier bases that provide better stability and precision.

Common Problems and Troubleshooting

Typical issues encountered with compound rests and potential solutions. Tips for preventing common problems during operation.Common issues with a compound rest can make work tricky. These problems include:

- Wobbling movements

- Difficulty in adjusting

- Wear and tear on parts

What are the typical issues with a compound rest?

Common problems include wobbling, sticking adjustments, and damaged components. These can affect accuracy and safety. It’s important to fix them quickly.

How to prevent common problems?

- Keep the lathe clean and free from debris.

- Lubricate moving parts regularly.

- Tighten screws to avoid loosening over time.

Choosing the Right Compound Rest for Your Lathe

Factors to consider based on lathe specifications and machining needs. Comparison of popular models and brands on the market.Buying the right kit metal lathe compound rest can make your work easier. First, look at your lathe’s size and type. Different models fit differently. Think about what you’ll make too. Do you need precision or speed? Next, check popular brands like Grizzly and Jet. They often score high in reviews. Here are key points:

- Size compatibility

- Material strength

- Ease of use

- Price range

Research helps you find the best fit!

What should I consider when buying a compound rest?

Consider the size, type, and your specific machining needs. This ensures the compound rest works well with your lathe and projects.

Conclusion

In summary, the kit metal lathe compound rest is essential for precise machining. It helps you adjust angles easily and improves accuracy. Understanding how to use it can make your projects better. We encourage you to explore tutorials and guides to deepen your skills. Hands-on practice will boost your confidence and help you create amazing metal projects!FAQs

What Is The Function Of The Compound Rest On A Kit Metal Lathe, And How Does It Influence The Machining Process?The compound rest on a metal lathe helps you hold and move your cutting tool. It lets you change the angle and position of the tool easily. This is important because it helps you make better shapes and cuts on the metal. By adjusting the compound rest, we can create smoother and more accurate parts.

How Do You Properly Set Up And Align The Compound Rest On A Kit Metal Lathe For Accurate Machining?To set up the compound rest on a metal lathe, first, make sure it’s clean. Then, loosen the screws and adjust it until it’s level. You can use a ruler or a square to check the angles. Once it’s aligned, tighten the screws to hold it in place. Now you’re ready for accurate machining!

What Are The Common Issues Or Challenges Faced When Using The Compound Rest On A Kit Metal Lathe, And How Can They Be Resolved?When using the compound rest on a kit metal lathe, you might have some problems. One common issue is the rest not moving smoothly. You can fix this by cleaning and oiling the parts. Another problem is getting the angles right. You can solve this by carefully measuring and adjusting the rest before you start. Finally, always check your setup to make sure everything is tight and secure.

What Materials Are Typically Used To Manufacture The Compound Rest On A Kit Metal Lathe, And How Does This Affect Its Durability And Performance?The compound rest on a kit metal lathe is usually made from steel or cast iron. These materials are strong and can handle a lot of pressure. Because of this, the compound rest lasts a long time and works well. Strong materials help keep the tools steady, so you get better results when you make things.

How Can A Hobbyist Or Beginner Safely And Effectively Use The Compound Rest To Create Complex Angled Cuts On A Kit Metal Lathe?To use the compound rest on a metal lathe safely, first, read the manual carefully. Then, make sure you wear safety goggles to protect your eyes. Adjust the angle of the compound rest to the cut you want. Move the cutting tool gently and watch your fingers. Always keep your hands away from the moving parts. Practice on scrap pieces before working on your final project.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Function Of The Compound Rest On A Kit Metal Lathe, And How Does It Influence The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on a metal lathe helps you hold and move your cutting tool. It lets you change the angle and position of the tool easily. This is important because it helps you make better shapes and cuts on the metal. By adjusting the compound rest, we can create smoother and more accurate parts.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align The Compound Rest On A Kit Metal Lathe For Accurate Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up the compound rest on a metal lathe, first, make sure it’s clean. Then, loosen the screws and adjust it until it’s level. You can use a ruler or a square to check the angles. Once it’s aligned, tighten the screws to hold it in place. Now you’re ready for accurate machining!”}},{“@type”: “Question”,”name”: “What Are The Common Issues Or Challenges Faced When Using The Compound Rest On A Kit Metal Lathe, And How Can They Be Resolved?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using the compound rest on a kit metal lathe, you might have some problems. One common issue is the rest not moving smoothly. You can fix this by cleaning and oiling the parts. Another problem is getting the angles right. You can solve this by carefully measuring and adjusting the rest before you start. Finally, always check your setup to make sure everything is tight and secure.”}},{“@type”: “Question”,”name”: “What Materials Are Typically Used To Manufacture The Compound Rest On A Kit Metal Lathe, And How Does This Affect Its Durability And Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest on a kit metal lathe is usually made from steel or cast iron. These materials are strong and can handle a lot of pressure. Because of this, the compound rest lasts a long time and works well. Strong materials help keep the tools steady, so you get better results when you make things.”}},{“@type”: “Question”,”name”: “How Can A Hobbyist Or Beginner Safely And Effectively Use The Compound Rest To Create Complex Angled Cuts On A Kit Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To use the compound rest on a metal lathe safely, first, read the manual carefully. Then, make sure you wear safety goggles to protect your eyes. Adjust the angle of the compound rest to the cut you want. Move the cutting tool gently and watch your fingers. Always keep your hands away from the moving parts. Practice on scrap pieces before working on your final project.”}}]}