Have you ever wondered how to make perfect threads on a metal lathe? Using a kit metal lathe threading dial can help you achieve that with ease. This simple tool can turn complicated tasks into fun, manageable projects.

Imagine crafting your own tools or parts for a school project. It sounds cool, right? With the right tools, you can create amazing things. A threading dial lets you make precise cuts and threads. This means better fits and stronger connections.

Many people think metal lathes are just for experts. But with the right guidance, anyone can learn to use one. The kit metal lathe threading dial is a great place to start. It helps you understand threading and machining like a pro.

Did you know that threading is an ancient technique? People have used it for thousands of years! Today, you can use modern tools to continue this fascinating craft. So, are you ready to explore the world of metalworking?

Kit Metal Lathe Threading Dial: Essential Tool For Precision

Understanding the Kit Metal Lathe Threading Dial

The kit metal lathe threading dial is a clever tool that helps in creating precise threads on metal pieces. It makes your work much easier by showing you exactly when to move the tool. Imagine trying to sew a straight line but not knowing where to go! This tool takes the guesswork out of threading. It’s essential for both beginners and experts. Knowing how to use it can improve your metalworking skills significantly. Isn’t it neat how a simple dial can change your projects?Understanding Metal Lathe Threading Dials

Definition and purpose of a threading dial. Importance in metalworking and machining processes.A threading dial is a tool on a metal lathe. It helps make precise threads on metal pieces. Using it ensures that threads are cut accurately and evenly. This tool is crucial in metalworking because it improves quality and saves time.

- Definition: A threading dial aids in creating threads on a workpiece.

- Purpose: It helps in achieving neat and strong threads.

- Importance: A threading dial increases accuracy in machining tasks.

What does a threading dial do?

A threading dial moves the carriage at the right time. This keeps the cutting tool in the correct position while making threads.

How to Choose the Right Threading Dial for Your Kit Metal Lathe

Factors to consider: compatibility, precision, and material. Recommendations based on lathe models and usage.Selecting the right threading dial for your kit metal lathe is crucial. First, consider compatibility with your lathe model. Next, look for precision in measurements. Finally, check the material; durable materials ensure long-lasting use. Each factor affects your lathe’s performance.

For recommendations:

- If you own a Mini Lathe, a simple dial with clear markings works best.

- Larger lathes may need precision dials with finer adjustments.

- Stainless steel dials resist wear and create strong threads.

What should I look for in a threading dial?

Look for compatibility, precision, and material. These elements affect your lathe’s performance and help you work more efficiently.

Installation Process for Threading Dials

Stepbystep guide to installing a threading dial. Common mistakes to avoid during installation.Installing a threading dial can seem tricky, but it’s actually pretty simple. First, gather your tools: a screwdriver, wrench, and—wait for it—patience! Start by removing the old dial carefully. Then place the new dial on your lathe, making sure it aligns well. Tighten the screws gently. Don’t turn it into a wrestling match!

| Common Mistakes | How to Avoid |

|---|---|

| Forgetting to align properly | Double-check alignment before tightening. |

| Using the wrong tools | Ensure you have the right size tools on hand. |

| Over-tightening screws | Tighten gently to avoid breakage. |

Follow these simple steps, and you’ll be the threading dial hero in no time! Remember, practice makes perfect, even if your dial has a few “oops” moments!

Maintenance Tips for Longevity of Threading Dials

Regular cleaning and lubrication best practices. Signs that your threading dial may need repair or replacement.To keep your threading dial working well, remember to clean and oil it regularly. Dust and grime can slow it down. Use a soft cloth and machine oil for best results. Look for the following signs to know if it needs fixing:

- Unusual noises while operating

- Difficulties in movement

- Visible wear or damage

Taking care of your dial means it will last longer and work better. Don’t wait until it breaks. Regular maintenance is key!

What are common signs that your threading dial needs repair?

Common signs include strange noises, trouble moving parts, or visible wear. If you notice any of these, it’s best to check your equipment.

Advanced Techniques Using Threading Dials

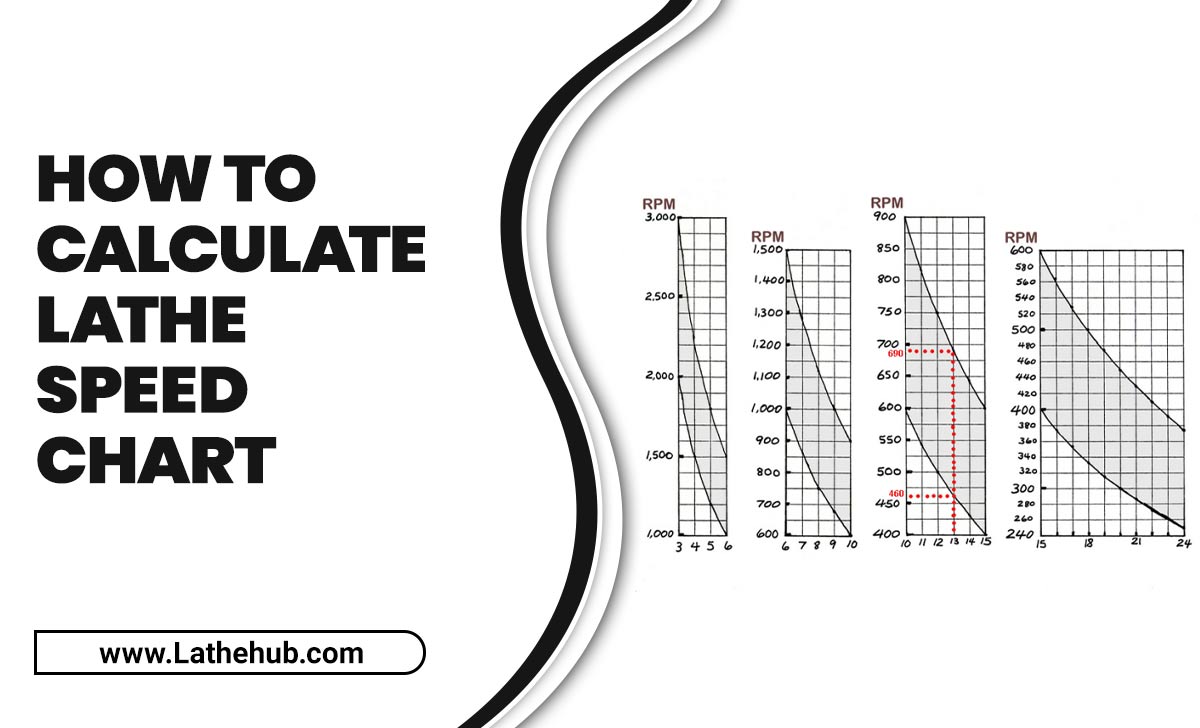

How to achieve different thread pitches and types. Tips for precision threading with a dial.To create different thread pitches, first, use your threading dial wisely. Each click moves you closer to the perfect thread. For instance, a pitch of 1.0 mm or 0.5 mm is easy when you know how to adjust your dial. Precision is key! Keep the dial steady while turning. A little wiggle could lead to disaster. Always double-check your settings! Also, remember, a coffee break helps clear the mind—just don’t let the coffee spill on your lathe!

| Thread Pitch | Dial Setting |

|---|---|

| 1.0 mm | 4 clicks |

| 0.5 mm | 8 clicks |

Common Problems and Troubleshooting

Identifying issues with threading dials during use. Solutions for improving threading accuracy.Sometimes, using a threading dial can feel like trying to teach a cat to swim—frustrating and messy! Problems often arise when the dial doesn’t align correctly, leading to uneven threads. Don’t fret; there are easy fixes! First, check if the dial is calibrated. If it’s off, adjustments can really help. Also, clean the dial regularly. Dust and grease can be sneaky little troublemakers. Here’s a quick table to remember key fixes:

| Problem | Solution |

|---|---|

| Misalignment | Calibrate the dial |

| Slippery dial | Clean regularly |

| Uneven threading | Check speed settings |

If your threads look like a messy spaghetti dinner, remember these tips! With a little effort, your threading dial will behave like a well-trained puppy.

Comparative Analysis of Popular Threading Dials in the Market

Review of the top brands and models available. Features, pricing, and user feedback comparison.Choosing the right threading dial can feel overwhelming. Many brands compete for attention, each with its unique features. Let’s look at a few favorites. For instance, Brand A boasts precision and durability, while Brand B shines with its user-friendly design. Prices vary, with some models costing less than a pizza! Don’t forget user reviews—people love to share their triumphs and mishaps. Below is a quick comparison of top options:

| Brand | Features | Price Range | User Feedback |

|---|---|---|---|

| Brand A | High precision, durable materials | $150 – $200 | Great for experts! |

| Brand B | User-friendly design | $100 – $150 | Perfect for beginners! |

| Brand C | Compact, lightweight and portable | $75 – $120 | Good for small projects! |

In the end, the best choice depends on your needs and budget. So, whether you’re a pro or just starting, there’s a threading dial for you!

Resources and Further Reading

Recommended books, websites, and forums for metalworking enthusiasts. Workshops and online courses for advanced learning.If you’re eager to learn more about metalworking, plenty of resources await you! Check out some great books and trusted websites that cover everything from basic techniques to advanced tips. Forums can connect you with fellow metal enthusiasts who love to share advice and laughter. Don’t miss the chance to attend workshops or online courses. They can take your skills to the next level—without turning you into a metal monster! Below is a handy table:

| Resource Type | Recommended Resource |

|---|---|

| Books | “The Metalworker’s Guide” |

| Websites | MetalworkingTalk.com |

| Forums | PracticalMachinist.com |

| Workshops | Local Maker Space |

| Online Courses | Udemy – Metalworking 101 |

Conclusion

In summary, a metal lathe threading dial is essential for precise threading. It helps you align your cuts accurately, making your projects smoother and more professional. Remember to practice using it on scrap materials to build your confidence. We encourage you to explore tutorials and guides online for more tips. Happy machining, and enjoy your creative projects!FAQs

What Is The Purpose Of A Threading Dial On A Kit Metal Lathe, And How Does It Improve Threading Accuracy?A threading dial is a tool on a metal lathe that helps you make threaded parts. It shows you the right spot to start cutting threads again after you move the piece. This way, your threads line up perfectly. By using the threading dial, you get better quality and more accurate cuts. It’s like having a map that guides you to the right place!

How Do You Properly Set Up And Use A Threading Dial When Cutting Threads On A Metal Lathe?To set up a threading dial on a metal lathe, start by making sure your lathe is turned off. Then, you move the tool to the starting mark for your thread. Next, look at the threading dial and choose the right number for your thread count. When you’re ready, you turn on the lathe and move the tool slowly while watching the threading dial. When the dial gets to your chosen number, you can move the tool down to make the next cut.

What Are The Differences Between Using A Threading Dial And A Thread Cutting Tool For Producing Threads On A Lathe?A threading dial helps you measure and line up cuts to make threads on a lathe. You use it to know when to move the cutting tool. A thread cutting tool actually does the cutting and shapes the metal into threads. So, the threading dial helps you set up, while the thread cutting tool does the work of cutting.

How Can You Troubleshoot Common Issues That Arise When Using A Threading Dial On A Kit Metal Lathe?To fix problems with a threading dial on a metal lathe, you can check a few things. First, make sure the lathe is set at the right speed. If the dial isn’t moving smoothly, clean any dirt or oil from it. Check that the dial is lined up correctly. Finally, if threads don’t match, recheck the settings and try again.

Are There Specific Maintenance Tips Or Techniques To Ensure The Longevity And Precision Of A Threading Dial On A Metal Lathe?To keep your threading dial on a metal lathe working well, clean it regularly. Dust and dirt can make it less accurate, so use a soft cloth. Check for any loose parts and tighten them if needed. If it gets stiff, a little oil can help it move better. Always be careful when using it, so it stays in good shape for a long time.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Is The Purpose Of A Threading Dial On A Kit Metal Lathe, And How Does It Improve Threading Accuracy? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial is a tool on a metal lathe that helps you make threaded parts. It shows you the right spot to start cutting threads again after you move the piece. This way, your threads line up perfectly. By using the threading dial, you get better quality and more accurate cuts. It’s like having a map that guides you to the right place!”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Use A Threading Dial When Cutting Threads On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a threading dial on a metal lathe, start by making sure your lathe is turned off. Then, you move the tool to the starting mark for your thread. Next, look at the threading dial and choose the right number for your thread count. When you’re ready, you turn on the lathe and move the tool slowly while watching the threading dial. When the dial gets to your chosen number, you can move the tool down to make the next cut.”}},{“@type”: “Question”,”name”: “What Are The Differences Between Using A Threading Dial And A Thread Cutting Tool For Producing Threads On A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial helps you measure and line up cuts to make threads on a lathe. You use it to know when to move the cutting tool. A thread cutting tool actually does the cutting and shapes the metal into threads. So, the threading dial helps you set up, while the thread cutting tool does the work of cutting.”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues That Arise When Using A Threading Dial On A Kit Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with a threading dial on a metal lathe, you can check a few things. First, make sure the lathe is set at the right speed. If the dial isn’t moving smoothly, clean any dirt or oil from it. Check that the dial is lined up correctly. Finally, if threads don’t match, recheck the settings and try again.”}},{“@type”: “Question”,”name”: “Are There Specific Maintenance Tips Or Techniques To Ensure The Longevity And Precision Of A Threading Dial On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your threading dial on a metal lathe working well, clean it regularly. Dust and dirt can make it less accurate, so use a soft cloth. Check for any loose parts and tighten them if needed. If it gets stiff, a little oil can help it move better. Always be careful when using it, so it stays in good shape for a long time.”}}]}