Have you ever wondered how metal is shaped into amazing tools and parts? One of the secrets lies in a powerful machine called a metal lathe. It’s quite fascinating! But what makes some lathes better than others? That’s where kit metal lathe torque comes in.

Torque is a simple word, but it carries a lot of power. This force helps the lathe cut through metal smoothly. Imagine trying to carve a pumpkin with a dull knife. It’s tough, right? Now, picture using a sharp one. It’s much easier! The same idea applies to metal lathes. High torque means better cutting performance.

In this article, we will explore the world of kit metal lathes. You’ll learn how torque affects their performance. Plus, we’ll share tips to help you choose the right lathe for your needs. Get ready to dive into an exciting journey of metalworking!

Understanding Kit Metal Lathe Torque For Precision Machining

Understanding Kit Metal Lathe Torque

When using a kit metal lathe, torque is crucial. It helps the machine spin the workpiece effectively. But how much torque do you need? Too little and you can’t cut well. Too much can damage the part. Many kit lathes allow you to adjust torque, giving you control over precision and speed. Did you know that the right torque can make your metalworking smoother and more enjoyable? Discover how mastering torque can elevate your projects!What is Torque in Metal Lathes?

Definition of torque in the context of metal lathes. Importance of torque for machining operations.Torque in metal lathes is the twisting force that helps shape materials. It is crucial for getting the right cut and finish. Without enough torque, cuts may be rough or uneven. Strong torque allows the lathe to work through tough materials efficiently. It ensures accuracy, making the machining process smoother.

What is the importance of torque in metal lathes?

Torque affects the power and control of a lathe. Here are key reasons why torque matters:

- It helps create precise shapes.

- It allows for faster machining.

- It improves tool life by reducing wear.

In simple terms, enough torque is essential for quality work on a lathe. The right balance leads to great results in every project!

Factors Influencing Torque in Metal Lathes

Role of motor power and speed. Impact of material type on torque requirements.Many things can change how much torque a metal lathe needs. One big factor is motor power. A stronger motor turns faster and gives more torque. Another factor is the material you use. Harder materials need more torque to cut smoothly. Softer materials are easier and require less. To summarize:

- Motor power: More power means more torque.

- Material type: Harder materials need higher torque.

Understanding these factors helps you choose the right settings for your lathe. This way, you can do your work safely and efficiently.

What is the effect of motor speed on torque?

Higher motor speed generally increases the torque output. It allows the lathe to operate more efficiently, especially for different materials.

Impact of material type on torque requirements:

- Soft materials require less torque.

- Hard materials need more torque to cut.

How to Measure Torque on a Metal Lathe

Tools and techniques for measuring torque. Interpreting torque readings for effective machining.Measuring torque on a metal lathe is like checking if your trusty bike is ready for a race. You need some cool tools: a torque wrench is your best buddy here! This tool helps you twist just right, making sure your projects don’t get too loose or too tight. Always remember, too much torque might result in a tangled mess. So, after you measure, interpret those readings wisely. The right torque speeds up machining like a cheetah on roller skates!

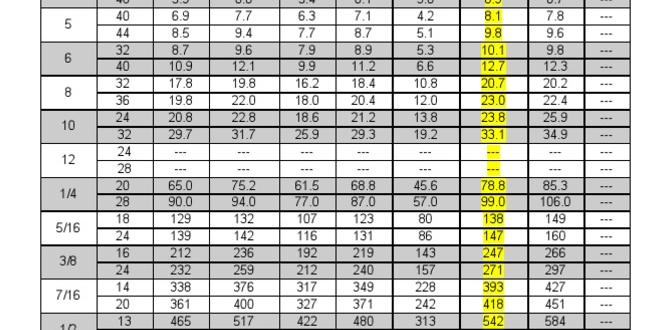

| Tools | Purpose |

|---|---|

| Torque Wrench | Measures and applies precise torque |

| Torque Calibrator | Verifies torque tool accuracy |

| Digital Torque Meter | Displays real-time torque values |

Choosing the Right Kit Metal Lathe for Your Needs

Key specifications to consider (torque, size, accessories). Comparing popular brands and models in the market.Choosing a kit metal lathe can be exciting, but it’s essential to find the right one. Consider the following key specifications:

- Torque: Higher torque offers better performance.

- Size: Choose a size that fits your workspace.

- Accessories: Look for helpful extra tools.

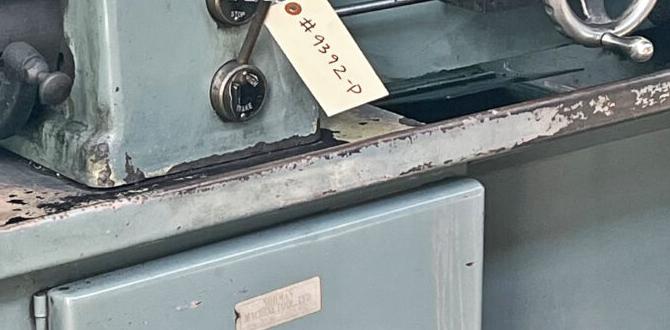

Many brands have different offerings. For example, some popular options are Grizzly, Jet, and South Bend. Compare their features and prices. This way, you will find the best lathe for your needs.

What features should I look for in a metal lathe?

Focus on torque, size, and accessories. These features will make your projects easier and more fun!

Tuning Your Metal Lathe for Optimal Torque

Adjustments to maximize torque efficiency. Maintenance tips to sustain torque performance.Tuning your metal lathe can feel like teaching a cat to swim—challenging but achievable! Start by making small adjustments to the lathe’s settings. This helps maximize torque efficiency so you can work smoothly. Regular maintenance is key; clean the gears and lubricate them often. A happy lathe equals better performance! Trust me, your metal lathe will thank you by not turning into an angry machine. Remember, a well-tuned lathe is an artist’s best friend!

| Tip | Description |

|---|---|

| Adjust Settings | Fine-tune speed and feed rate for max torque. |

| Clean Regularly | Dust and grime can slow things down! |

| Lubricate | Keep moving parts smooth and happy. |

Common Issues Affecting Torque and How to Solve Them

Identifying signs of low torque performance. Troubleshooting techniques and solutions.Low torque can cause problems when using your metal lathe. Signs include poor cutting, excessive noise, and slow machine responses. If you notice these issues, try these troubleshooting steps:

- Check for loose connections.

- Inspect the drive belt for wear.

- Ensure proper lubrication of all parts.

By identifying these signs early, you can fix issues and improve performance.

What can I do if the torque is low?

If you’re facing low torque on your lathe, tighten connections, replace worn parts, and ensure everything is clean and lubricated.Applications of Torque in Metal Lathe Operations

Types of projects where torque plays a critical role. Examples of machining tasks requiring specific torque settings.Torque is super important in metal lathe work. It helps shape projects like metal rods and gears. For instance, turning a hard steel piece requires high torque to cut smoothly. On the other hand, softer materials need less torque. A well-set torque ensures the machine runs safely and accurately. Nobody wants a flying lathe part! Here’s a quick look:

| Project Type | Torque Requirement |

|---|---|

| Metal Rods | High Torque |

| Aluminum Parts | Medium Torque |

| Wooden Turnings | Low Torque |

Choosing the right torque setting makes all the difference. It can turn a boring block of metal into a shiny masterpiece!

Future Trends in Metal Lathe Torque Technology

Innovations in lathe design and torque optimization. Predictions for advancements and their implications on usability.Future metal lathes are all about being smarter and stronger. New designs will focus on torque optimization, which makes them work better without extra effort. Imagine a lathe that adjusts its power like a superhero lifting weights! Upcoming advancements might lead to machines that know when to speed up or slow down. This means less wasted energy and more time for fun things, like creating cool projects. Who knew metalworking could be this exciting?

| Trend | Description |

|---|---|

| Smart Controls | Machines will sense material and adjust torque automatically. |

| Energy Efficiency | Less power used means lower bills and happier planet! |

| User-Friendly Designs | New interfaces will make it easy for anyone to use. |

Conclusion

In conclusion, understanding kit metal lathe torque helps you work safely and efficiently. Higher torque means better cutting power and smoother results. Always match your lathe to your projects! To improve your skills, explore more resources or tutorials on lathe operation. Remember, practice makes perfect, so dive in and start creating!FAQs

Sure! Here Are Five Questions Related To Kit Metal Lathe Torque:Sure! Here are some questions about a kit metal lathe and torque: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins metal pieces and cuts them into shapes. 2. What does torque mean? Torque is the strength you use to turn something. It helps make the lathe work better. 3. How do you know how much torque is needed? You check the tool’s instructions. It tells you the right amount of torque for different jobs. 4. Why is torque important in a lathe? Torque helps the lathe cut metal smoothly. Without enough torque, it can’t work well. 5. Can you change the torque on a lathe? Yes, you can adjust the torque using special settings or tools. This helps you work on different metals easily.

Sure! Please provide the question you’d like me to answer.

What Factors Influence The Torque Output Of A Kit Metal Lathe During Operation?The torque output of a kit metal lathe depends on a few key things. First, the motor’s power helps determine how much force the lathe can make. Second, the type of material you are cutting affects how hard the lathe has to work. Lastly, the speed settings you choose can change how much torque is produced. More speed usually means less torque, and less speed gives more torque.

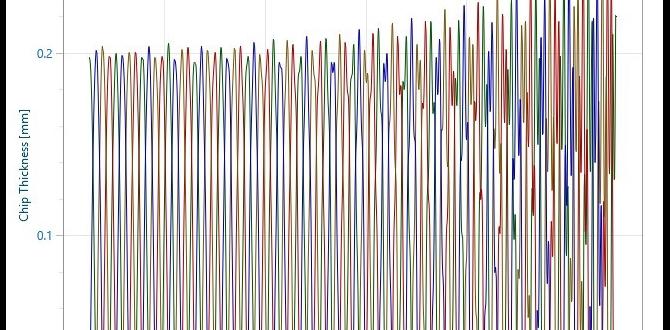

How Can Adjusting The Spindle Speed Affect The Torque Required For Machining Different Materials On A Lathe?When you change the spindle speed on a lathe, it can change how hard the machine has to work. If you use a faster speed, the tool cuts through material quicker. This usually requires less torque, which is the twisting force. But for harder materials, you might need more torque to keep cutting smoothly. So, adjusting the speed helps you control how much power the machine uses.

What Is The Relationship Between Torque And Cutting Tool Life When Using A Kit Metal Lathe?When you use a kit metal lathe, torque is the twist force that helps cut metal. If you use too much torque, it can wear down your cutting tool faster. This means the tool may need to be replaced sooner. So, you want just the right amount of torque for a longer tool life. By finding that balance, we can make our tools last longer while still working well.

How Do Different Lathe Configurations And Designs Impact The Torque Capabilities Of A Metal Lathe Kit?Different lathe designs can change how much twisting power, or torque, they have. A heavier lathe usually has more torque. This helps when you cut tougher metal without slowing down. Also, the shape of the lathe affects balance and stability, giving you better control while working. So, picking the right design is key to handling different projects easily.

What Methods Can Be Employed To Calculate Or Measure The Torque Being Applied To The Workpiece In A Metal Lathe?To measure the torque on a metal lathe, you can use a torque wrench. This tool shows how much twisting force you’re using. Another way is to use a torque sensor. This sensor gives you a reading of the torque in real time. You could also check the power used by the machine to estimate the torque.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Kit Metal Lathe Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some questions about a kit metal lathe and torque: 1. What is a metal lathe? A metal lathe is a machine that shapes metal. It spins metal pieces and cuts them into shapes. 2. What does torque mean? Torque is the strength you use to turn something. It helps make the lathe work better. 3. How do you know how much torque is needed? You check the tool’s instructions. It tells you the right amount of torque for different jobs. 4. Why is torque important in a lathe? Torque helps the lathe cut metal smoothly. Without enough torque, it can’t work well. 5. Can you change the torque on a lathe? Yes, you can adjust the torque using special settings or tools. This helps you work on different metals easily.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Factors Influence The Torque Output Of A Kit Metal Lathe During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The torque output of a kit metal lathe depends on a few key things. First, the motor’s power helps determine how much force the lathe can make. Second, the type of material you are cutting affects how hard the lathe has to work. Lastly, the speed settings you choose can change how much torque is produced. More speed usually means less torque, and less speed gives more torque.”}},{“@type”: “Question”,”name”: “How Can Adjusting The Spindle Speed Affect The Torque Required For Machining Different Materials On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you change the spindle speed on a lathe, it can change how hard the machine has to work. If you use a faster speed, the tool cuts through material quicker. This usually requires less torque, which is the twisting force. But for harder materials, you might need more torque to keep cutting smoothly. So, adjusting the speed helps you control how much power the machine uses.”}},{“@type”: “Question”,”name”: “What Is The Relationship Between Torque And Cutting Tool Life When Using A Kit Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you use a kit metal lathe, torque is the twist force that helps cut metal. If you use too much torque, it can wear down your cutting tool faster. This means the tool may need to be replaced sooner. So, you want just the right amount of torque for a longer tool life. By finding that balance, we can make our tools last longer while still working well.”}},{“@type”: “Question”,”name”: “How Do Different Lathe Configurations And Designs Impact The Torque Capabilities Of A Metal Lathe Kit?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different lathe designs can change how much twisting power, or torque, they have. A heavier lathe usually has more torque. This helps when you cut tougher metal without slowing down. Also, the shape of the lathe affects balance and stability, giving you better control while working. So, picking the right design is key to handling different projects easily.”}},{“@type”: “Question”,”name”: “What Methods Can Be Employed To Calculate Or Measure The Torque Being Applied To The Workpiece In A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure the torque on a metal lathe, you can use a torque wrench. This tool shows how much twisting force you’re using. Another way is to use a torque sensor. This sensor gives you a reading of the torque in real time. You could also check the power used by the machine to estimate the torque.”}}]}