Have you ever wondered how a simple piece of metal becomes a perfect shape? The magic often lies in lathe adjustments. Whether you’re a hobbyist or a seasoned pro, understanding these adjustments is crucial.

Imagine you’re working on a project and something goes wrong. The cuts aren’t clean, or the machine doesn’t cooperate. Frustrating, right? This is when proper lathe adjustments come into play. They can save your project and your sanity.

Many people upgrade their machines with CNC retrofit kits. These kits turn regular machines into powerful tools. With the right adjustments, you can achieve precision like never before. Isn’t that exciting?

In this article, we’ll explore the world of lathe adjustments for metal lathes and CNC retrofits. Join us as we dive into tips that can help you work smarter, not harder.

Essential Lathe Adjustments For Metal Lathe Cnc Retrofit

Lathe Adjustments for CNC Retrofit

Lathe adjustments are essential for optimizing performance in metal lathes, especially during a CNC retrofit. Understanding how to calibrate your machine can greatly enhance its precision. Simple tweaks, like adjusting tension and alignment, can change your outcome dramatically. Did you know that a slight misalignment can lead to significant errors in your projects? Proper adjustments ensure smooth operation and better results. Uncovering the secrets to lathe adjustments can make you a machining expert.Understanding Lathe Adjustments

Definition and importance of lathe adjustments. Common issues arising from improper adjustments.Lathe adjustments are essential for keeping your machine accurate and effective. These adjustments allow the lathe to work smoothly, ensuring better cuts and finishes. Without proper tuning, you may face issues like uneven surfaces or damaged parts. Over time, this can lead to wasted materials and time. It’s crucial to understand these settings to produce quality work.

What are common problems with lathe adjustments?

Common issues include :

- Unbalanced workpieces can cause vibrations.

- Incorrect tool height leads to poor cuts.

- Worn bearings can affect precision.

These problems can hurt your project and delay completion. Regular adjustments help prevent these headaches.

Common Lathe Adjustments and Procedures

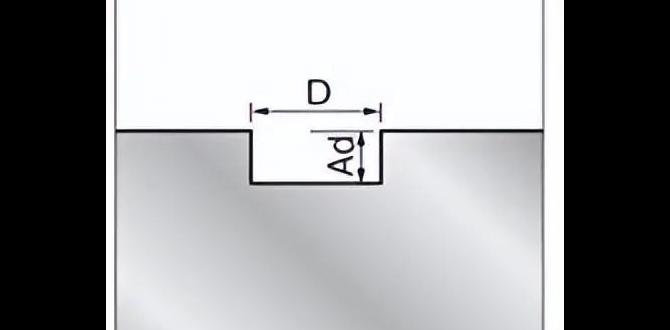

Stepbystep guide to essential lathe adjustments. Tools required for making adjustments effectively.Lathe adjustments are key to achieving precise results. Start by checking the tailstock and make sure it aligns with the spindle. A tiny misalignment can turn a straight rod into a wavy noodle! For tools, grab a caliper, a feeler gauge, and a trusty screwdriver. Keeping these handy will make adjustments smoother than butter. If you’re a little lost, don’t worry; you can always consult the manual or ask a friend who knows their lathe from their elbow!

| Tool | Purpose |

|---|---|

| Caliper | Measures dimensions |

| Feeler Gauge | Checks gaps |

| Screwdriver | Adjusts nuts and bolts |

Benefits of CNC Retrofit for Metal Lathes

Enhanced precision and accuracy in machining. Increased efficiency and reduced manual labor.The magic of CNC retrofitting can turn an old metal lathe into a savvy machining machine. One big perk is enhanced precision and accuracy. Parts fit together like puzzle pieces, leaving no room for embarrassing mistakes. Plus, who wants to sweat over manual labor? CNC upgrades crank up efficiency, letting machines do the heavy lifting. Think of it as giving your lathe a brain—now it does the thinking while you eat a donut!

| Benefits | Description |

|---|---|

| Precision | Better fitting parts and less waste! |

| Efficiency | More work done in less time—hello, extra breaks! |

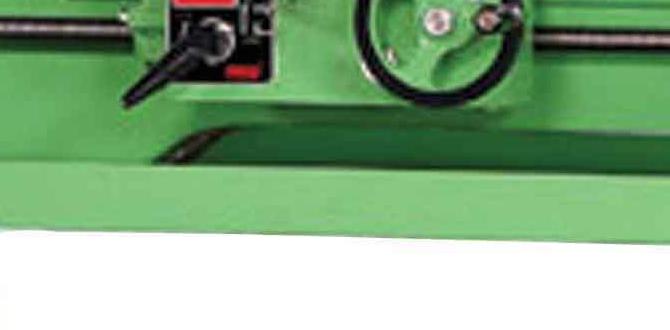

Preparing Your Metal Lathe for CNC Retrofit

Assessing compatibility of your current lathe. Checklist for necessary modifications and upgrades.Before upgrading your lathe to CNC, check if it suits your needs. Look closely at your current lathe’s age and model. Some older lathes may need extra work. Use this checklist for necessary modifications and upgrades:

- Electrical system needs updating.

- Check the drive mechanism condition.

- Ensure your lathe can handle new software.

- Look for any physical damage to the machine.

With these steps, you can make sure your lathe is ready for an exciting upgrade!

How do I know if my lathe is compatible with CNC upgrades?

Check the model and manufacturing year of your lathe. Older models may not support modern CNC features. Look for reviews and guides on your specific model for more information.

Steps to Successfully Retrofit Your Metal Lathe

Detailed guide to retrofitting a metal lathe with CNC technology. Common pitfalls to avoid during the retrofitting process.Retrofitting a metal lathe with CNC technology can improve its performance. Follow these steps carefully for success:

- Choose the right CNC kit for your lathe.

- Prepare your workspace for assembly.

- Install new components using the provided instructions.

- Calibrate settings to ensure accuracy.

Avoid common mistakes to save time and frustration:

- Don’t skip the calibration step.

- Avoid using incompatible parts.

- Double-check your wiring connections.

By following these tips, you can enjoy a more efficient lathe!

What is the benefit of CNC retrofitting?

CNC retrofitting can greatly enhance precision and speed in machining tasks.

Maintenance and Calibration After Retrofit

Ongoing maintenance tips for retrofitted lathes. Importance of regular calibration for optimal performance.After a lathe adjustments metal lathe cnc retrofit, keeping the machine in good shape is key. Regular maintenance helps it run smoothly. Here are some tips:

- Clean the machine parts often.

- Check and oil the moving parts.

- Look for any loose screws or bolts.

- Make sure the belts are tight and not worn out.

Also, calibrating your lathe is very important. Calibration ensures that the machine cuts accurately. Check it regularly to keep everything precise.

Why is regular calibration important?

Regular calibration helps maintain accuracy and prevents costly mistakes. It keeps your projects on track and improves overall quality.

Case Studies: Successful CNC Retrofits

Examples of metal lathe retrofits and their outcomes. Lessons learned from various retrofit projects.CNC retrofits can transform old metal lathes into modern machines that hum like a well-tuned guitar. Take, for instance, a workshop that upgraded its machine. After retrofitting, they noticed 20% faster production and fewer mistakes. That’s great news, right? Another company learned that careful planning is key. They found that a thorough assessment before starting can save time and money. Highlights from these projects show that small tweaks can lead to big wins.

| Company | Outcome | Lesson Learned |

|---|---|---|

| Workshop A | 20% faster production | Plan carefully |

| Company B | Improved accuracy | Assess needs first |

Future Trends in Lathe Adjustments and CNC Technology

Innovations on the horizon for metal lathes. The role of automation in lathe adjustments and CNC retrofitting.Exciting changes abound in the world of metal lathes. Innovations are popping up that make lathe adjustments simpler and faster. Imagine a machine that thinks for itself! Well, automation is making that dream come true. It’s like giving your lathe a brain. With CNC retrofitting, your old lathe can get fancy updates without being thrown out. This makes it quicker and more efficient. Soon, we might just see lathes doing the cha-cha while they work!

| Innovation | Benefit |

|---|---|

| Automation | Faster adjustments |

| CNC Retrofitting | Updated features |

Conclusion

In conclusion, lathe adjustments are vital for precision. A CNC retrofit enhances your metal lathe’s capabilities. You gain better control and accuracy for your projects. Remember to regularly check settings and practice adjustments. This way, you’ll become more skilled and confident. If you want to learn more, explore tutorials and guides about CNC upgrades and lathe maintenance. Happy machining!FAQs

What Are The Key Adjustments To Consider When Retrofitting A Metal Lathe With Cnc Capabilities?When adding CNC (Computer Numerical Control) to a metal lathe, you need to make some important changes. First, you have to install motors to move the tools and the workpiece. Next, you should add sensors so the machine knows where everything is. Lastly, you need a computer to control the lathe and make it work smoothly. These adjustments help the lathe cut metal more precisely.

How Do You Properly Calibrate The Axes And Tool Offsets After A Cnc Retrofit On A Metal Lathe?To calibrate the axes on your CNC metal lathe, first, make sure the machine is turned off. Then, move the tool to a known starting point, like the center of the workpiece. Next, set the machine to recognize this starting position. For tool offsets, measure the tool’s length from the machine’s zero position. Finally, enter this measurement into the machine’s settings so it knows the correct position of the tool.

What Common Issues Arise During The Lathe Adjustment Process In A Cnc Retrofit, And How Can They Be Resolved?During the lathe adjustment in a CNC (Computer Numerical Control) retrofit, you might face some common problems. One issue is the machine not moving smoothly. You can fix this by checking the oil levels and greasing moving parts. Another problem could be incorrect speed settings. You can solve this by carefully adjusting the settings to match the material you are using. Finally, loose connections can cause errors. Tightening all cables and checking connections will help.

How Can You Ensure Accurate Spindle Alignment During A Cnc Retrofit Of A Metal Lathe?To ensure accurate spindle alignment during a CNC retrofit of a metal lathe, you can take a few important steps. First, use a dial indicator to check the spindle’s position. This tool helps you see if the spindle is straight. Next, adjust the spindle until it’s perfectly aligned. Finally, check it again to make sure it’s still straight before using the lathe. This way, you’ll have better results when you cut metal.

What Software Options Are Available For Controlling A Retrofitted Cnc Metal Lathe, And How Can They Assist In Making Precise Adjustments?There are several software options for controlling a retrofitted CNC metal lathe. Some popular ones are Mach3, LinuxCNC, and Fusion 360. These programs help you tell the lathe what to do with simple commands. They can make precise adjustments by guiding the machine to cut exactly where you want. This way, you can create parts that fit perfectly.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Adjustments To Consider When Retrofitting A Metal Lathe With Cnc Capabilities? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When adding CNC (Computer Numerical Control) to a metal lathe, you need to make some important changes. First, you have to install motors to move the tools and the workpiece. Next, you should add sensors so the machine knows where everything is. Lastly, you need a computer to control the lathe and make it work smoothly. These adjustments help the lathe cut metal more precisely.”}},{“@type”: “Question”,”name”: “How Do You Properly Calibrate The Axes And Tool Offsets After A Cnc Retrofit On A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate the axes on your CNC metal lathe, first, make sure the machine is turned off. Then, move the tool to a known starting point, like the center of the workpiece. Next, set the machine to recognize this starting position. For tool offsets, measure the tool’s length from the machine’s zero position. Finally, enter this measurement into the machine’s settings so it knows the correct position of the tool.”}},{“@type”: “Question”,”name”: “What Common Issues Arise During The Lathe Adjustment Process In A Cnc Retrofit, And How Can They Be Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “During the lathe adjustment in a CNC (Computer Numerical Control) retrofit, you might face some common problems. One issue is the machine not moving smoothly. You can fix this by checking the oil levels and greasing moving parts. Another problem could be incorrect speed settings. You can solve this by carefully adjusting the settings to match the material you are using. Finally, loose connections can cause errors. Tightening all cables and checking connections will help.”}},{“@type”: “Question”,”name”: “How Can You Ensure Accurate Spindle Alignment During A Cnc Retrofit Of A Metal Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To ensure accurate spindle alignment during a CNC retrofit of a metal lathe, you can take a few important steps. First, use a dial indicator to check the spindle’s position. This tool helps you see if the spindle is straight. Next, adjust the spindle until it’s perfectly aligned. Finally, check it again to make sure it’s still straight before using the lathe. This way, you’ll have better results when you cut metal.”}},{“@type”: “Question”,”name”: “What Software Options Are Available For Controlling A Retrofitted Cnc Metal Lathe, And How Can They Assist In Making Precise Adjustments? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are several software options for controlling a retrofitted CNC metal lathe. Some popular ones are Mach3, LinuxCNC, and Fusion 360. These programs help you tell the lathe what to do with simple commands. They can make precise adjustments by guiding the machine to cut exactly where you want. This way, you can create parts that fit perfectly.”}}]}