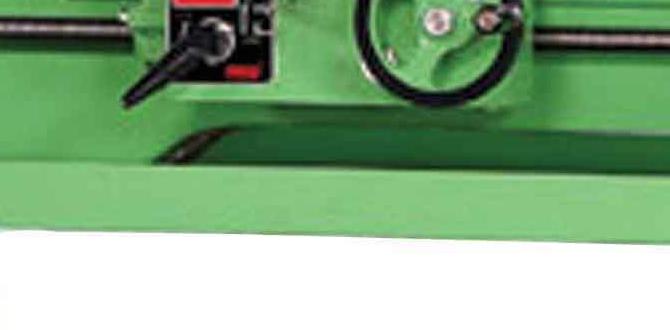

Have you ever wondered how to get precise results when using a metal lathe? One key factor is tailstock alignment. If the tailstock isn’t aligned, your projects might not turn out right. Imagine trying to make a perfect cylinder, only to find it wobbly and uneven! That can be super frustrating.

Getting the tailstock adjustments right is more important than you might think. Just a tiny misalignment can lead to big errors. Did you know that many experienced machinists spend time fine-tuning their lathes? It’s true! They know that perfect alignment can save time and effort.

In this article, we will explore the importance of lathe adjustments, especially tailstock alignment. You’ll learn some quick tips to check alignment and improve your projects. Are you ready to dive in and make your metal lathe work like a pro?

Lathe Adjustments: Metal Lathe Tailstock Alignment Guide

Lathe Adjustments: Metal Lathe Tailstock Alignment

Aligning the tailstock on a metal lathe is essential for accuracy. A misaligned tailstock can ruin your projects, leading to wasted materials and time. Did you know that a simple adjustment can greatly improve precision? Start by checking the tailstock’s alignment with the spindle. Use a test bar to ensure everything is straight. Making these important lathe adjustments will enhance your machining skills and help you achieve professional-quality results in your work.The Importance of Tailstock Alignment

Consequences of misalignment on workpiece accuracy. Benefits of properly aligned tailstock for machining efficiency.Proper tailstock alignment is vital for successful machining. If the tailstock is misaligned, it can lead to inaccurate workpieces. This means parts may not fit correctly. You could waste materials and time. On the other hand, a properly aligned tailstock helps create smooth and precise cuts. This boosts machining efficiency and saves you money. In short, alignment leads to better results!

Why is tailstock alignment important?

Misalignment can cause poor fitting and wasted materials. It means less quality and more rework. Correct alignment allows smoother operations, which saves both time and resources.

- Accurate workpieces every time.

- Higher productivity in machining.

- Longer tool life and less wear.

Common Tailstock Alignment Issues

Identifying signs of tailstock misalignment. Common causes of tailstock alignment problems.Aligning the tailstock on a lathe can be tricky. If you notice uneven cuts or a poor finish, your tailstock might be off. Common signs include wobbling tools and crooked workpieces. The misalignment often happens due to wear and tear, or if it wasn’t tightened properly. Sometimes, even a tiny burr can cause big issues! Keep an eye out for these problems, or you might end up with more twists than a pretzel in your projects.

| Signs of Misalignment | Common Causes |

|---|---|

| Uneven surface finish | Improper tightening |

| Wobbling tools | Wear and tear |

| Crooked workpieces | Burrs or debris |

Tools Required for Tailstock Alignment

Essential tools for accurate adjustments. Recommended measuring instruments for precision.Getting your tailstock aligned is easier with the right tools. First, you need a good dial indicator to measure small changes. It’s like a magic wand for precision! A straightedge helps ensure everything is level. You might also grab a caliper for measuring distances. Having these tools can save you from unplanned wobbles. After all, no one wants a tailstock that dances to its own tune!

| Tool | Purpose |

|---|---|

| Dial Indicator | Measures tiny adjustments |

| Straightedge | Checks for level alignment |

| Caliper | Measures lengths accurately |

Step-by-Step Guide to Aligning the Tailstock

Initial setup and preparation instructions. Detailed procedures for adjusting the tailstock.Getting ready to align the tailstock is like prepping for a fun adventure! First, make sure your metal lathe is clean. A messy lathe can lead to messy results. Check that the tailstock is snug against the bed and has no wobbles. Use a dial indicator for precise movements, because accuracy matters. What’s the point of a crooked tailstock? None, right?

| Step | Action |

|---|---|

| 1 | Clean your lathe’s bed. |

| 2 | Check tailstock fit. |

| 3 | Use a dial indicator. |

| 4 | Make adjustments. |

With these easy steps, you’ll soon have your tailstock aligned! It’s like giving your lathe a fancy makeover. Remember, a happy lathe means a happy you! So, let’s get started!

Testing Tailstock Alignment

Methods to verify proper alignment after adjustments. Importance of calibration and repeated testing.To check if your tailstock is aligned correctly, several methods can help. One simple way is to use a dial indicator. This tool will show how far off the tailstock is from the center. Remember to measure both close and far from the spindle. Calibration is crucial. Check your alignment often to keep everything in line. It’s like tuning a musical instrument—practice makes perfect!

- Use a dial indicator for accurate measurement.

- Check alignment at different distances from the spindle.

- Regular checks help maintain precision.

Why is tailstock alignment important?

Proper alignment ensures better accuracy in your projects, reduces wear, and prevents accidents.

How often should I test the alignment?

- Check after any major adjustments.

- Regular tests, such as weekly, help maintain quality.

Preventative Maintenance for Tailstock Alignment

Tips for maintaining alignment over time. Regular inspection routines for metal lathes.To keep your metal lathe’s tailstock aligned, regular checks are important. Here are some tips:

- Inspect the tailstock often for any loose parts.

- Clean the alignment surfaces to prevent dirt buildup.

- Use a dial indicator to check the alignment regularly.

- Lubricate moving parts to ensure smooth operation.

Frequent inspections help catch problems early. This can save you time and money in repairs. An aligned tailstock makes your work precise and easier.

How often should I check tailstock alignment?

You should check your tailstock alignment at least once a month or anytime you notice changes in your work. This keeps everything running smoothly!

Advanced Techniques for Precision Tailstock Alignment

Utilizing specialized equipment for enhanced accuracy. Techniques for aligning in different machining scenarios.Getting your tailstock aligned is like giving your lathe a new pair of glasses! Specialized equipment can help you measure with great precision. This means fewer wobbles and better cuts. For tough machining tasks, try using a dial indicator. It makes alignment as easy as pie, and we all love pie, right? Here’s a quick table that lays out some techniques:

| Technique | Best For | Special Equipment |

|---|---|---|

| Dial Indicator Method | Precision Work | Dial Indicator |

| Feeler Gauge Technique | Quick Checks | Feeler Gauges |

| Straight Edge Method | General Tasks | Precision Straight Edge |

Remember, attention to alignment can save you time and materials. And who doesn’t want to avoid a machining mishap that makes your project look like it was designed by a toddler? Keep smiling and spinning!

Common Mistakes to Avoid

Frequent errors made during tailstock adjustments. Tips to prevent misalignment in the first place.Many people make silly mistakes with tailstock adjustments. One common error is ignoring the setup before starting. Always check your tailstock for proper alignment; misaligned tailstock can ruin your work. Another mistake is not tightening the lock screws enough. If they’re loose, it can lead to slips during cutting. A little humor: a loose tailstock is like a wobbly chair – not fun!

| Common Mistakes | Prevention Tips |

|---|---|

| Ignoring initial setup | Always check alignment first! |

| Loose lock screws | Tighten them well before starting. |

| Skipping test runs | Always do a test cut for practice. |

To sum it up, avoid these mistakes and save yourself from some serious frustration. Remember, perfecting tailstock adjustments makes your projects smoother and more fun!

Resources for Further Learning

Recommended books and guides on lathe adjustments. Online tutorials and forums for continuous improvement.Learning about lathe adjustments can be fun! Many great resources are available. Here are some that will help you improve:

- Books like “Metalworking Essentials” and “Lathe Techniques” offer step-by-step guides.

- Online tutorials on YouTube show real-life demonstrations.

- Forums like “Machinist’s Corner” let you ask questions and share tips.

Using these resources, you can become an expert at lathe adjustments. Keep practicing and learning!

What are some good resources for learning about lathe adjustments?

Helpful books and guides along with online video lessons and forums support learning lathe adjustments effectively.

Conclusion

In conclusion, aligning your metal lathe’s tailstock is essential for precise work. Proper adjustments ensure your projects are accurate and smooth. You can check alignment using simple tools, like a dial gauge. Practice these techniques to improve your skills. For more tips and detailed guides, explore further resources on lathe maintenance. Happy machining!FAQs

Here Are Five Questions Related To Lathe Adjustments And Tailstock Alignment In A Metal Lathe:Sure! You can adjust the lathe to make sure it cuts smoothly. If the tailstock isn’t lined up right, your workpiece may not turn properly. To fix this, you should check the alignment often. Make small changes and test as you go. This will help you make good parts every time!

Sure! Please provide the question you would like me to answer.

What Are The Key Steps Involved In Aligning The Tailstock Of A Metal Lathe For Accurate Workpiece Machining?To align the tailstock of a metal lathe, you start by checking its position. First, move the tailstock close to the headstock. Then, use a tool to make sure both ends are in line. Adjust the tailstock if they are not lined up. Finally, tighten everything so it stays in place while you work.

How Can Misalignment Of The Tailstock Affect The Precision And Quality Of The Final Machined Parts?If the tailstock is not lined up correctly, it can cause problems with the parts we are making. The tailstock helps hold the piece steady. If it’s off, the machine might cut unevenly. This means our final parts might not fit right or look good. Always check the tailstock to keep everything perfect!

What Tools Are Typically Used To Check And Adjust The Alignment Of The Tailstock On A Metal Lathe?To check and adjust the tailstock on a metal lathe, you can use a few simple tools. A dial indicator helps measure how straight everything is. A square helps you see if the tailstock is at a right angle. Finally, a wrench is used to tighten or loosen the bolts. With these tools, you can make sure the tailstock lines up correctly.

How Frequently Should Tailstock Alignment Be Checked And Adjusted During Regular Lathe Maintenance?You should check the tailstock alignment on your lathe every time you start a new project. It’s also a good idea to check it if you notice any problems with your workpieces. Adjust it if you see any misalignment. Regular checks help your lathe work better and make your projects smoother.

What Common Symptoms Indicate That The Tailstock May Be Misaligned, And How Can These Issues Be Resolved?If the tailstock is misaligned, you might see uneven cuts or the piece wobbles while spinning. You may also notice extra noise or vibration. To fix it, you can adjust the tailstock so it lines up properly with the rest of the machine. Make small changes and check if it helps. Testing with a piece of wood can show if your adjustments work.