Have you ever wondered how to make your metal lathe work better? Proper lathe alignment plays a huge role in how smooth and accurate your projects turn out. It’s like tuning a musical instrument; the right adjustments can create beautiful results!

Many people forget about the foot brake on their metal lathe. This important feature helps in keeping you safe while working and can improve your overall experience. But how do you make sure everything is aligned just right?

In this article, we’ll share some handy lathe alignment tips. If you want to craft amazing projects with ease, these tips are just what you need. So, are you ready to learn how to get your lathe performing at its best?

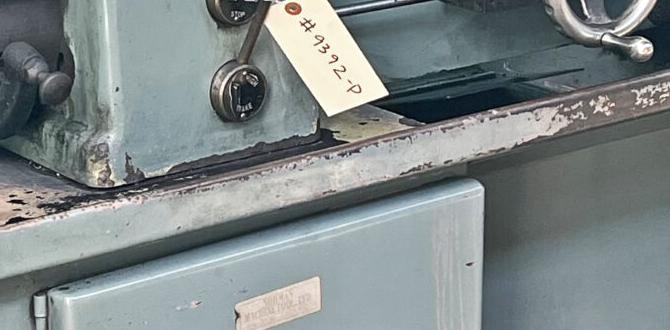

Lathe Alignment Tips: Mastering Metal Lathe Foot Brake Techniques — When It Comes To Operating A Metal Lathe, Precision And Stability Are Key To Achieving High-Quality Results. One Crucial Aspect Of Maintaining That Precision Is Ensuring Proper Lathe Alignment, Particularly When It Comes To The Foot Brake System. Below Are Some Essential Lathe Alignment Tips Specifically Focused On Optimizing The Performance Of Your Metal Lathe’S Foot Brake. 1. Understand The Importance Of Lathe Alignment Proper Lathe Alignment Not Only Ensures Better Accuracy In Your Machining Processes But Also Extends The Life Of Your Equipment. Misalignment Can Lead To Increased Wear On Components And Can Affect The Performance Of The Foot Brake System, Which Is Essential For Safe Operation. 2. Check Leveling Of The Lathe Before You Dive Into More Complex Adjustments, It’S Crucial To Ensure That Your Lathe Is Level. Use A Precision Level On The Bed Of The Lathe To Confirm That It Is Perfectly Horizontal. Adjust The Feet Of The Lathe Accordingly To Achieve A Stable Base. 3. Inspect The Foot Brake Mechanism Regularly Inspect The Foot Brake For Wear And Functionality. A Well-Aligned Brake Is Essential For Immediate Stopping And Maintains Overall Safety. Ensure The Brake Pedal Engages Smoothly And Connects Adequately To The Braking Mechanism. 4. Adjust The Tailstock Alignment The Alignment Of The Tailstock Can Significantly Influence The Overall Alignment Of The Lathe. Make Sure The Tailstock Is Aligned Parallel To The Lathe’S Bed. Use A Dial Indicator To Measure Any Deviation And Make Necessary Adjustments. 5. Calibrate The Headstock Ensure That The Headstock Is Properly Aligned With The Tailstock. Misalignment Can Cause Heavy Wear On Tooling And Affect Cut Quality. Make Slight Adjustments As Needed To Keep Both Elements In Line. 6. Utilize Alignment Tools Consider Investing In Alignment Tools Or Devices That Simplify The Process Of Checking And Adjusting Your Lathe’S Alignment. Tools Such As A Dial Indicator Or Laser Alignment Systems Can Save Time And Improve Accuracy. 7. Test Cuts After Adjustments Once You Have Completed Your Alignment Adjustments, It’S Essential To Perform Test Cuts To Verify That The Lathe Is Operating Correctly. Pay Attention To The Quality Of The Finish And Any Potential Vibrations Or Wobbling That May Signify Remaining Alignment Issues. Conclusion Proper Lathe Alignment Is Critical When Working With A Metal Lathe, Particularly Concerning The Effectiveness Of The Foot Brake System. By Following These Lathe Alignment Tips, You Can Enhance The Performance And Safety Of Your Lathe, Ensuring That Your Projects Are Completed With Precision And Efficiency. Regular Maintenance And Checks Will Keep Your Equipment In Top Shape For Years To Come.

Lathe Alignment Tips for Metal Lathe Foot Brake

Want your metal lathe to work smoothly? Proper alignment is crucial! First, check the lathe’s level. An uneven machine can lead to poor results. Next, ensure the foot brake engages effectively; it should stop the machine quickly. A good tip is to tighten the brake spring for better performance. Did you know that even small adjustments can significantly improve your outcomes? Stay attentive to these simple steps for a more precise and safer metalworking experience.Understanding Lathe Alignment

Importance of proper alignment in metal lathes. Effects of misalignment on machining accuracy and tool life.Proper lathe alignment is like the secret sauce for smooth machining. Without it, you risk tool wear and accuracy that resembles a wobbly bicycle wheel. Imagine cutting metal, and your lathe acts like it’s dancing the cha-cha. That’s misalignment! It can lead to crooked cuts, wasted materials, and head-scratching frustration. Investing time in alignment saves money and gives your tools a longer life. Plus, who doesn’t want their projects to look sharp?

| Effect of Misalignment | Impact |

|---|---|

| Poor Accuracy | Inaccurate cuts and dimensions. |

| Tool Life | Shortens the lifespan of tools. |

| Material Waste | Increased scrap and wasted effort. |

Common Misalignment Issues

Identifying signs of misalignment and their impact. Typical causes of misalignment in metal lathes.Misalignment can be a sneaky thief, robbing you of precision in your work with metal lathes. Look out for odd vibrations or uneven cuts, as these can signal issues. Common causes include improper installation, worn-out parts, or even a foot brake that decided to take a vacation. It’s like a metal dance party gone wrong!

| Signs of Misalignment | Typical Causes |

|---|---|

| Odd vibrations | Improper installation |

| Uneven cuts | Worn-out parts |

| Strange noises | Foot brake issues |

By spotting these signs early, you can keep your lathe running smoothly and avoid any mishaps. Remember, a well-aligned lathe is a happy lathe!

Step-by-Step Alignment Procedure

Tools and equipment needed for alignment. Detailed process for aligning the metal lathe.To align your metal lathe, start with a few essential tools. You’ll need a level, a wrench, and a dial gauge. These tools help ensure everything is straight and balanced.

Follow this process for proper alignment:

- Check the lathe bed with a level.

- Adjust the feet until the bed is flat.

- Use the dial gauge to measure alignment accuracy.

- Tighten the bolts securely.

- Recheck with the level again.

This careful process helps improve your lathe’s performance.

What tools do I need to align a metal lathe?

You need a level, a wrench, and a dial gauge for proper alignment of a metal lathe.How can I ensure my lathe is level?

Use a level to check the lathe bed. Adjust the feet until it is perfectly flat.Foot Brake Adjustment Techniques

Importance of foot brake in precision cutting. Techniques to ensure proper foot brake operation.A foot brake plays a key role in precision cutting on a metal lathe. It helps you stop the machine quickly and safely, reducing risk during work. Proper foot brake adjustment ensures smooth operation. Here are some effective techniques:

- Check the brake pedal height for comfort.

- Test the brake response regularly.

- Adjust tension for quick stops.

- Lubricate the moving parts.

Using these tips can enhance your cutting accuracy and safety. Remember, a well-adjusted foot brake is essential for a better working experience.

Why is foot brake adjustment important?

Foot brake adjustment is vital because it ensures safety and precision. A well-adjusted brake helps avoid accidents and improves cutting quality.

Regular Maintenance Practices

Schedule and importance of regular checks. Maintenance tips to prevent misalignment issues.Keeping your lathe in great shape is easy with regular checks. Schedule these checks monthly. This simple act can prevent big problems later. When your lathe works well, it makes better parts. Here are some helpful maintenance tips:

- Check for wear and tear on the foot brake.

- Ensure the alignment is correct.

- Lubricate moving parts regularly.

- Clean the machine to avoid debris buildup.

Doing these tasks keeps your lathe running smoothly and can save you time and money.

How often should you maintain a metal lathe?

You should maintain a metal lathe at least once a month. This helps catch issues before they become serious.

What happens if you skip maintenance?

If you skip maintenance, misalignment and breakdowns can occur. This can cost you time and resources for repairs.

Advanced Alignment Techniques

Using laser alignment tools for precision. Advanced methods for troubleshooting complex alignment problems.Using laser tools can make your lathe work much better. They help you see if everything is in line. It’s a fast way to check and fix problems. For tricky issues, try these advanced methods:

- Check the surface with a level.

- Use a dial indicator for accuracy.

- Examine all the connections carefully.

These steps will help you solve complex alignment problems easily. Doing it right will keep your projects running smoothly.

What are laser alignment tools?

Laser alignment tools use beams of light to find misalignments quickly and accurately.

Case Studies and Real-World Applications

Examples of successful lathe alignment in industry. Lessons learned from alignment failures and fixes.In real-world factories, proper lathe alignment has saved machines from becoming fancy paperweights. For instance, one shop improved its production by 30% after fixing alignment issues. That’s more than enough to boost a coffee break duration! Lessons from failures often come with a hearty laugh; one technician learned not to use a banana as a measuring tool. Remember, accurate tools lead to smoother operations! Here’s a quick look at some case studies:

| Industry | Success Stories | Failures and Fixes |

|---|---|---|

| Aerospace | 30% increase in precision after alignment | Misaligned parts caused delays; fixed in a week |

| Automotive | Boosted assembly line speed by 25% | Some gears went *clunk*, but adjustments worked |

| Military Equipment | Alignment saved $1M in repairs | One team measured with shoelaces and learned fast! |

These examples show how right adjustments pay off big time, while wrong ones lead to hiccups and chuckles.

Conclusion

In conclusion, aligning your metal lathe is essential for smooth operation. Remember to check the foot brake regularly to ensure safety. Use simple tools for alignment, and take your time to do it right. We encourage you to practice these tips and explore more resources for better results. With patience, you’ll become a skilled lathe operator!FAQs

Here Are Five Related Questions On The Topic Of Lathe Alignment And Foot Brake For A Metal Lathe:To make sure your lathe works well, you need to align it properly. This means setting it up so everything is straight and even. A foot brake is important because it helps you stop the lathe easily when you need to. This can keep you safe while working. Always check your equipment to make sure it’s ready to use!

Sure! Just ask your question, and I’ll give you a simple answer!

What Are The Key Steps To Accurately Align A Metal Lathe To Ensure Precision Machining?To align a metal lathe, first, check that it’s level. Use a level tool to see if it sits flat. Next, adjust the tailstock and cross-slide for straightness. Tighten all screws firmly. Finally, run the lathe and listen for any unusual sounds.

How Can Improper Lathe Alignment Affect The Performance And Safety Of A Foot Brake System?If the lathe is not properly aligned, it can make the brake parts uneven. This can cause the brakes to work poorly, which means you might not stop as quickly. It can also make the brakes wear out faster. This could be dangerous while driving because you need good brakes to stay safe.

What Tools Are Recommended For Checking And Adjusting The Alignment Of A Metal Lathe?To check and adjust the alignment of a metal lathe, you can use a few tools. A level helps you see if the lathe is straight. A dial indicator measures tiny distances to check for problems. A straightedge shows if the bed is flat. Using these tools helps make sure your lathe works well!

How Often Should A Metal Lathe Be Aligned And Serviced To Maintain Optimal Performance, Including The Foot Brake?You should check and align your metal lathe every few months. This helps it work well and makes it last longer. We should also service it regularly, like cleaning and oiling the parts. Don’t forget to check the foot brake to make sure it works safely. Doing these tasks will keep everything running smoothly!

What Are The Common Signs Of Misalignment In A Metal Lathe, And How Can They Impact The Effectiveness Of The Foot Brake?Common signs of misalignment in a metal lathe are uneven cuts and strange noises. You might also notice that parts don’t fit together well. These problems can make it hard to use the machine safely. If the lathe is not straight, the foot brake might not work properly. This can make stopping the machine difficult, which is dangerous.