Have you ever wondered how a simple piece of metal can be turned into something amazing? A metal lathe does just that. It spins metal to shape it into different forms. But did you know that keeping your lathe aligned is key to getting great results?

Imagine trying to ride a bike with wobbly wheels. It would be hard and maybe even unsafe! Similarly, a misaligned lathe can cause problems. This is where lathe alignment tips come in handy. They help you check and fix your lathe to ensure everything runs smoothly.

Even the gear train of a metal lathe needs attention. Did you know that a small mistake in the gear train can lead to big issues? By following some easy tips, you can keep your lathe in top shape. Let’s explore how proper alignment can save you time and improve your projects.

Lathe Alignment Tips For Metal Lathe Gear Train Success When Working With A Metal Lathe, Achieving Perfect Alignment Is Crucial For Effective Operation And Optimal Results. Proper Alignment Ensures That The Gear Train Functions Smoothly, Leading To Improved Accuracy And Reduced Wear On The Machine. Here Are Some Essential Lathe Alignment Tips That Can Help You Maintain Your Metal Lathe Gear Train’S Functionality While Enhancing Overall Performance. 1. Understand The Basics Of Lathe Alignment Before Diving Into Specific Tips, It’S Vital To Understand The Fundamental Concepts Of Lathe Alignment. The Primary Aspects To Consider Are The Headstock, Tailstock, And Bed. All These Components Should Be Aligned Correctly To Ensure That The Workpiece Rotates Evenly. 2. Regular Calibration Checks Frequent Calibration Checks Will Ensure Your Metal Lathe Remains Aligned Over Time. Use A Dial Indicator To Measure Runout On The Spindle And Ensure It Stays Within Acceptable Limits. This Can Prevent Undue Stress On The Gear Train. 3. Check And Adjust The Tailstock The Tailstock Can Often Shift Over Time, Affecting Alignment. Regularly Check Its Position Relative To The Headstock. Make Adjustments As Needed To Keep The Centerline Consistent. This Will Help In Reducing The Strain On The Gear Train During Operations. 4. Inspect The Bed For Levelness An Unlevel Bed Can Lead To Misalignment Across The Entire Lathe System. Use A Level To Check The Bed’S Alignment, Adjusting As Necessary To Maintain A Flat And Level Work Environment. This Setting Is Critical For The Correct Functioning Of The Gear Train. 5. Monitor Gear Train Wear And Tear Over Time, The Gear Train Can Experience Wear That Affects Lathe Performance. Regularly Inspect The Gears For Chips, Cracks, Or Signs Of Excessive Wear. Replace Worn Gears Promptly To Maintain The Integrity Of The Metal Lathe. 6. Use Alignment Tools There Are Specialized Tools Available For Lathe Alignment That Can Save Time And Ensure Accuracy. Consider Investing In Alignment Kits Designed Specifically For Metal Lathe Adjustments. They Can Help You Achieve Precise Alignment More Efficiently. 7. Keep Clean And Lubricated Dirt, Debris, And Lack Of Lubrication Can Hamper The Performance Of The Gear Train. Keep Your Metal Lathe Clean And Well-Lubricated To Ensure Smooth Operation. Regular Maintenance Will Prolong The Life Of Your Lathe And Its Components. 8. Learn From The Experts Engaging With Experienced Machinists Can Provide Invaluable Insights Into Effective Lathe Alignment Techniques. Online Forums, Local Workshops, Or Machinist Clubs Can Be Beneficial Resources For Learning Best Practices And Common Pitfalls. Conclusion Implementing These Lathe Alignment Tips Can Greatly Enhance The Performance And Longevity Of Your Metal Lathe Gear Train. Remember That Regular Maintenance, Calibration Checks, And A Proactive Approach To Alignment Will Lead To Better Results, Efficiency, And Satisfaction In Your Machining Projects. By Staying Vigilant And Informed, You Can Keep Your Lathe Operating At Its Best.

Lathe Alignment Tips for Metal Lathe Gear Train

Getting your metal lathe aligned perfectly can feel like a puzzle. Did you know that proper alignment prevents costly mistakes and prolongs your machine’s life? Start by checking the bed for levelness. A simple bubble level can help here. Next, align the tailstock and headstock; they need to be straight with each other. Regular maintenance of the gear train is vital too. Clean gears ensure smooth operation, making your work easier and more precise. Remember, a well-aligned lathe gives you better results!Understanding Lathe Alignment

Definition and importance of lathe alignment. Common issues caused by misalignment.Lathe alignment is how well the parts of the lathe line up. Proper alignment is key for smooth operation. If things are off, it can lead to problems. Common issues include:

- Inaccurate cuts

- Excessive wear and tear

- Vibration and noise

- Shorter tool life

Even a small misalignment can cause big headaches. Keeping your lathe aligned helps your projects succeed and tools last longer.

Why is lathe alignment important?

Lathe alignment ensures precise machining, which improves product quality and efficiency.

Tools Required for Lathe Alignment

List of essential tools for accurate alignment. Stepbystep guide on how to use these tools.For precise lathe alignment, certain tools are key. Start with a dial indicator, a reliable tool to measure small distances. A straightedge helps check for flat surfaces. You’ll also need a level to ensure everything is even. Don’t forget feeler gauges for gap checking. Here’s a quick list:

- Dial Indicator

- Straightedge

- Level

- Feeler Gauges

To use these, first, secure the lathe. Then place the straightedge along critical areas. Measure gaps with feeler gauges. Finally, adjust using the dial indicator for accurate readings.

What tools are necessary for lathe alignment?

For lathe alignment, tools like a dial indicator, straightedge, and level are essential.

Common Challenges in Lathe Alignment

Identification of frequent alignment problems. Solutions and preventive measures.Many people face problems when aligning a lathe. Some common issues include:

- Misaligned bed

- Worn bearings

- Incorrect setup of the gear train

What are some common lathe alignment problems?

Common lathe alignment problems include misalignment of the bed and worn-out gears. These can affect the machine’s performance and accuracy.

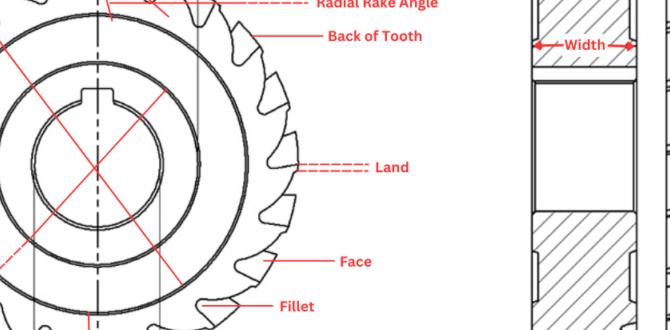

Impact of Gear Train on Lathe Performance

Explanation of gear train components and their functions. How gear train misalignment affects lathe operations.The gear train in a lathe is like the heart of a drum. It has different parts that work together to make things spin smoothly. Key components include gears and shafts, each playing a special role. If these parts get misaligned, it’s like trying to dance with two left feet! Misalignment can lead to poor cutting, noise, and even damage. Imagine your lathe performing the cha-cha while you want a waltz—definitely not the right tune!

| Component | Function |

|---|---|

| Gears | Transmit power and motion |

| Shafts | Support and hold the gears |

| Bearings | Reduce friction for smoother operation |

Advanced Alignment Techniques

Description of advanced methods for precision alignment. Case studies highlighting successful advanced alignments.Achieving precision with a metal lathe requires more than just turning knobs. Advanced alignment techniques help you set things straight—literally! Using tools like laser alignment makes your work accurate. A case study showed that a shop improved its production speed by 30% with this technique. Another method involves using dial indicators for tweaks that save time and material. Remember, even the best gear train can’t perform well if it’s out of alignment. Just like a well-tuned guitar, your lathe needs to be perfectly aligned!

| Technique | Benefits |

|---|---|

| Laser Alignment | Increases accuracy by up to 25%! |

| Dial Indicators | Quick adjustments save time and materials. |

Maintaining Lathe Alignment Over Time

Regular maintenance tips to ensure longterm alignment. Signs that indicate the need for realignment.To keep your lathe working well, regular maintenance is key. Check it often to ensure it stays aligned. Here are some tips:

- Clean the machine regularly.

- Tighten loose screws and bolts.

- Inspect gears for wear and damage.

- Adjust belts for proper tension.

If you notice problems, do not ignore them. Signs of needing realignment include:

- Inconsistent cuts and finishes.

- Unusual vibrations during use.

- Hearing strange noises while operating.

Staying on top of these tasks helps ensure your lathe runs smoothly for years.

What are the signs that indicate the need for realignment?

You should realign your lathe if you see uneven cuts, hear strange noises, or feel excessive vibrations.

Expert Recommendations and Best Practices

Key tips from industry professionals. Recommended resources for ongoing learning.Learning from experts can greatly improve your lathe skills. Here are some tips from industry professionals:

- Always check your lathe alignment regularly.

- Use quality tools for the best results.

- Practice safety measures while working.

- Join a hobbyist group for shared knowledge.

For ongoing learning, consider these resources:

- Online courses focusing on metalworking.

- Books about lathe techniques.

- YouTube channels offering demonstrations.

What are key tips for lathe alignment?

Regular checks and proper setup improve performance.

Conclusion

In summary, aligning your metal lathe gear train is essential for precise machining. Check your machine regularly for wear and tear. Make sure to adjust and tighten any loose components. By following these tips, you’ll improve your lathe’s performance. Keep learning about lathe maintenance to ensure the best results in your projects. Happy machining!FAQs

Sure! Here Are Five Related Questions About Lathe Alignment, Specifically Focused On Metal Lathe Gear Trains:Sure! Lathe alignment is important to make sure our metal lathe works well. When we align it, the gears fit together better. This helps us make smooth and accurate cuts on the metal. If gears are not aligned, it can cause problems and make a mess. Checking the alignment often is a good idea to keep everything in great shape.

Sure! Please ask your question, and I’ll be happy to help.

What Are The Key Steps To Ensure Accurate Alignment Of The Gear Train In A Metal Lathe?To keep the gear train in a metal lathe aligned, we need to follow some simple steps. First, check that all parts are clean and free of dirt. Next, make sure the gears fit together well without being too tight. Then, use a straight edge to line everything up straight. Finally, tighten all the screws carefully so nothing shifts. This helps the machine work smoothly!

How Can You Diagnose Misalignment Issues In The Gear Train Of A Lathe, And What Symptoms Should You Look For?To find misalignment in a lathe’s gear train, we can look for specific signs. First, listen for strange noises, like grinding or clunking sounds. Next, check if the lathe vibrates more than normal when it’s running. Also, watch for uneven cuts in the material we are working on. If you notice any of these symptoms, it’s time to check the alignment of the gears.

What Tools And Techniques Are Recommended For Checking The Alignment Of Gears And Shafts On A Metal Lathe?To check the alignment of gears and shafts on a metal lathe, you can use a few simple tools. A dial indicator helps measure tiny movements accurately. A straightedge helps you see if things are straight. Use a ruler to check distances between parts. Always check everything carefully to ensure they line up well!

How Does Proper Gear Train Alignment Affect The Overall Precision And Performance Of A Metal Lathe?When you align the gears on a metal lathe properly, everything works better. Good alignment helps the machine cut metal accurately. This means you get smooth and precise shapes without mistakes. If the gears are misaligned, the lathe can make rough cuts and may not last long. So, keeping the gears in the right place helps the lathe perform well.

What Common Mistakes Should Be Avoided When Aligning The Gear Train In A Metal Lathe?When aligning the gear train in a metal lathe, avoid these mistakes. First, make sure you don’t skip any steps in the instructions. Also, check that the gears fit together nicely and are not too tight or loose. Be careful not to forget to clean the parts before putting them together. Finally, always double-check your work to catch any problems early.