Have you ever seen a metal lathe in action? It’s fascinating to watch as raw metal transforms into precise shapes. This process gets even better when we talk about lathe automation. Imagine machines that can work all on their own! How cool is that?

This article is your ultimate guide to lathe application. We’ll explore how automation changes everything for metal lathes. You’ll learn the different tasks these machines can handle and how they make work easier and faster.

Did you know that handling metal can be dangerous? With automation, we can reduce risks for workers. That makes metal lathe applications not just smarter but safer too!

So, are you ready to dive into the world of metal lathe automation? Let’s uncover the secrets and benefits of using a lathe like never before!

Lathe Application Guide: Metal Lathe Automation Explained

Lathe Application Guide: Metal Lathe Automation

Discover how metal lathe automation revolutionizes machining! With precise control and improved efficiency, automation helps craftsmen create unique parts faster than ever. Imagine shaping metal effortlessly, just like a pro. From reducing manual labor to enhancing safety, the benefits are remarkable. Have you ever wondered how manufacturers keep up with demand? Automated lathes provide a solution. Explore this guide and unlock the potential of metal lathe automation to elevate your projects!Understanding Metal Lathes

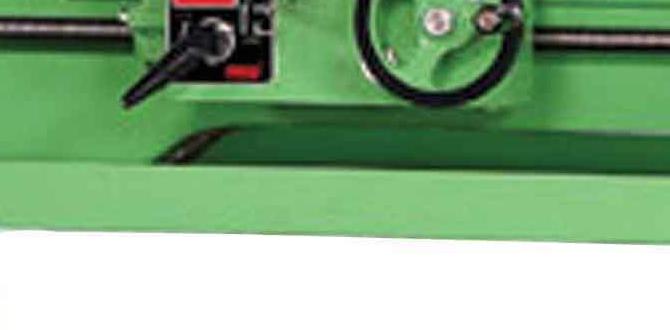

Definition and types of metal lathes. Key components and their functions.Metal lathes are machines that shape metal into different parts. Think of them like giant pencils that carve out designs! There are several types of metal lathes, such as manual, CNC, and automatic. Each type has its own charm and uses. Key parts include the spindle, which holds the metal, and the carriage, which moves the tool. This helps create smooth surfaces and precise cuts. It’s like having a mini robot artist in your workshop!

| Type of Metal Lathe | Function |

|---|---|

| Manual Lathe | User-operated for hands-on projects |

| CNC Lathe | Computer-controlled for accuracy |

| Automatic Lathe | Runs on its own, great for mass production |

Benefits of Metal Lathe Automation

Increased efficiency and productivity. Enhanced precision and consistency in production.Imagine your workshop buzzing like a beehive! Metal lathe automation can make that happen. First, it boosts efficiency. Machines can work longer without coffee breaks. This means you get more done in less time, like finishing your homework before recess! Next, there’s precision. Machines cut metal consistently, like a sharp knife slicing butter. No more wobbly edges or uneven surfaces. It’s like having a superhero in your shop, saving the day with every spin of the lathe!

| Benefits | Description |

|---|---|

| Increased Efficiency | Machines work tirelessly, producing more in less time. |

| Enhanced Precision | Each cut is exact, leading to flawless products. |

Common Applications of Metal Lathes

Manufacturing of machine parts. Tool and die making.Metal lathes are like the superheroes of manufacturing. They spin metal to create all sorts of parts used in machines. Imagine a magic wand that can turn a chunk of metal into something useful! That’s what happens in tool and die making, where metal lathes shape materials precisely. They help make tools that help other tools. It’s all very cool and sometimes a little nerdy, but hey, who doesn’t love a good tool, right?

| Application | Description |

|---|---|

| Manufacturing Parts | Transforms metal into machine parts like gears and shafts. |

| Tool Making | Shapes precise tools and dies for various tasks. |

Setting Up a Metal Lathe for Automation

Key considerations for automation setup. Necessary software and hardware requirements.Automating a metal lathe can boost your productivity. Here are some key points to consider:

- Workspace: Ensure you have enough room for the lathe and its automation parts.

- Sensors: Use sensors to measure distance and detect problems.

- Control system: A reliable computer and software is essential to run the automation.

For software needs, look for programs that are user-friendly. You’ll want to find software that connects well with your lathe machine. This ensures everything works smoothly together.

What software do I need for metal lathe automation?

You need control software that talks to your lathe. Look for programs made for automation and CNC operation to help with tasks. These make managing your lathe simple and effective.

Best Practices for Operating Automated Metal Lathes

Regular maintenance guidelines. Safety protocols during operation.Keeping an automated metal lathe in top shape is crucial for smooth operations. Regular maintenance ensures your lathe runs like a well-oiled machine. Check the oil levels, and clean the parts often. Remember, a happy lathe means fewer surprises!

Safety is another key player here. Always wear protective gear — it’s like giving your body a big hug when things get intense. Make sure guards are in place and that the area is tidy. A clean workspace keeps accidents at bay.

| Maintenance Task | Frequency |

|---|---|

| Check Oil Levels | Daily |

| Clean Components | Weekly |

| Inspect Equipment | Monthly |

So, remember: a neat workspace and regular check-ups can save the day and your sanity!

Future Trends in Metal Lathe Automation

Advances in automation technology. The impact of Industry 4.0 on metal lathe operations.Imagine a world where metal lathes are as smart as your pet goldfish, but without the need for food! Advances in automation technology show that metal lathes are getting a tech upgrade. They now use sensors and AI to act more like robots. With Industry 4.0 around, metal lathes can connect to the internet, making them smarter and faster. This tech revolution helps factories produce parts in record time. Who knew spinning metal could be so exciting?

| Automation Feature | Benefit |

|---|---|

| Sensors | Monitor performance constantly |

| AI Integration | Improves efficiency and precision |

| Internet Connectivity | Remote monitoring and control |

Case Studies: Successful Metal Lathe Automation Implementations

Examples from various industries. Lessons learned and outcomes achieved.Many industries have seen success with metal lathe automation. For instance, a car manufacturing plant automated their lathe processes, reducing production time by 30%. They learned that working together as a team brings out the best solutions. Another example is a small machine shop that upgraded to automated lathes. They increased accuracy and saw a 25% rise in profits. Remember, even the best machines can’t replace a good sense of humor on the shop floor!

| Industry | Outcome | Lessons Learned |

|---|---|---|

| Automotive | 30% faster production | Teamwork is key! |

| Machine Shops | 25% profit increase | Accuracy matters! |

Resources and Tools for Further Learning

Recommended books and online courses. Helpful software and community forums.Learning about metal lathes can be fun and informative! Here are some great tools to help you.

- Books: Look for titles like “Metalworking Basics” or “Lathe Essentials.” These offer helpful tips and tricks.

- Online Courses: Platforms like Udemy or Coursera provide easy courses on lathe automation.

- Software: Consider programs like Fusion 360 for design and simulation.

- Community Forums: Joining sites like Reddit or dedicated machining forums connects you with experienced makers.

These resources will help you master your lathe skills!

What are some good resources for metal lathe learning?

Books, online courses, software, and community forums make excellent learning tools in lathe automation.

Conclusion

In conclusion, using a lathe can greatly improve your metalworking projects. This guide shows you how to automate your lathe for better precision and efficiency. Remember, practice makes perfect! Start small and gradually tackle more complex tasks. For more tips and techniques, consider exploring additional resources on metal lathe automation. Happy machining!FAQs

Here Are Five Related Questions On The Topic Of Lathe Application And Metal Lathe Automation:Sure! A lathe is a machine that spins metal to shape it. We use lathes to make parts for cars, toys, and tools. Automating a metal lathe means using machines or computers to help it work better and faster. This makes it easier for workers and helps make lots of pieces quickly. Automating can also reduce mistakes and keep everyone safe.

Sure! Please give me the question you’d like me to answer.

What Are The Key Benefits Of Automating Metal Lathe Operations In A Manufacturing Environment?Automating metal lathe operations helps us work faster and make more parts. It reduces mistakes, so everything fits better. We can save money because machines don’t need breaks like people do. Plus, we can keep our workers safe by having them do different jobs away from the machines. Overall, it makes our work easier and our products better!

How Can Cnc Technology Enhance The Precision And Efficiency Of Metal Lathe Processes?CNC stands for Computer Numerical Control. It uses computers to control machines like lathes that shape metal. With CNC, we can make very exact cuts that are hard to do by hand. This means our metal parts fit together perfectly. Also, CNC machines can work faster, helping us finish our projects more quickly.

What Types Of Automation Solutions Are Commonly Used In Metal Lathe Applications?In metal lathe applications, we often use robots and computer controls. Robots can help move and place heavy metal parts. Computer controls make sure the lathe cuts the metal in the right shape. We can also use machines that change tools automatically, so we don’t have to do it by hand. These solutions make work faster and easier!

How Do Different Materials Affect The Automation Settings And Parameters For Metal Lathes?Different materials need different settings on metal lathes, which are machines that shape metal. For soft metals, like aluminum, we can use faster speeds and less force. Hard metals, like steel, need slower speeds and more force to cut properly. If we change the material, we must adjust the settings to make sure the machine works well and makes smooth parts.

What Are The Best Practices For Integrating Automated Systems With Existing Metal Lathe Machinery?To integrate automated systems with metal lathe machines, start by checking how everything connects. Make sure you understand the machines you already have. You’ll want to train your team on how to use the new system. Test everything before you fully use it. Lastly, keep an eye on the machines to ensure they work well together.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Application And Metal Lathe Automation:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that spins metal to shape it. We use lathes to make parts for cars, toys, and tools. Automating a metal lathe means using machines or computers to help it work better and faster. This makes it easier for workers and helps make lots of pieces quickly. Automating can also reduce mistakes and keep everyone safe.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Benefits Of Automating Metal Lathe Operations In A Manufacturing Environment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automating metal lathe operations helps us work faster and make more parts. It reduces mistakes, so everything fits better. We can save money because machines don’t need breaks like people do. Plus, we can keep our workers safe by having them do different jobs away from the machines. Overall, it makes our work easier and our products better!”}},{“@type”: “Question”,”name”: “How Can Cnc Technology Enhance The Precision And Efficiency Of Metal Lathe Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “CNC stands for Computer Numerical Control. It uses computers to control machines like lathes that shape metal. With CNC, we can make very exact cuts that are hard to do by hand. This means our metal parts fit together perfectly. Also, CNC machines can work faster, helping us finish our projects more quickly.”}},{“@type”: “Question”,”name”: “What Types Of Automation Solutions Are Commonly Used In Metal Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “In metal lathe applications, we often use robots and computer controls. Robots can help move and place heavy metal parts. Computer controls make sure the lathe cuts the metal in the right shape. We can also use machines that change tools automatically, so we don’t have to do it by hand. These solutions make work faster and easier!”}},{“@type”: “Question”,”name”: “How Do Different Materials Affect The Automation Settings And Parameters For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Different materials need different settings on metal lathes, which are machines that shape metal. For soft metals, like aluminum, we can use faster speeds and less force. Hard metals, like steel, need slower speeds and more force to cut properly. If we change the material, we must adjust the settings to make sure the machine works well and makes smooth parts.”}},{“@type”: “Question”,”name”: “What Are The Best Practices For Integrating Automated Systems With Existing Metal Lathe Machinery?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To integrate automated systems with metal lathe machines, start by checking how everything connects. Make sure you understand the machines you already have. You’ll want to train your team on how to use the new system. Test everything before you fully use it. Lastly, keep an eye on the machines to ensure they work well together.”}}]}