Have you ever wondered how skilled craftsmen create precise metal parts? One of the key tools they use is a metal lathe. This machine spins metal to shape it into various forms. But did you know that the lathe’s performance often hinges on a small yet mighty component? That’s right, it’s the belt!

A metal lathe belt helps connect the motor to the spindle. This connection powers the entire machine. Without a good belt, a lathe can struggle or even stop working. Imagine trying to ride a bike with a flat tire. It just doesn’t work, right?

In this application guide, we will explore why the lathe belt is so important. You’ll learn how to choose the right one for your metal lathe. Let’s dive into the fascinating world of metalworking!

Lathe Application Guide: Metal Lathe Belt Uses And Tips

Lathe Application Guide: Metal Lathe Belt

Understanding how to use a metal lathe can be exciting. The lathe application guide introduces key terms and concepts. It explains how a proper metal lathe belt works to keep your machine running smoothly. Did you know that the right belt can improve your project’s accuracy? Choosing the right belt affects your machine’s performance and longevity. This guide also offers tips on maintenance to ensure your lathe stays in top shape, making your projects fun and efficient.Understanding Metal Lathes

Definition and purpose of metal lathes. Key components and how they function.Metal lathes are machines that shape metal into pieces. They work by spinning metal while tools cut it to the right size. Think of it like making a wooden top! The main parts include the bed, which is the base, the headstock that holds the spinning piece, and the tailstock which supports the other end. Each piece plays its part, just like players on a sports team. Without them, it’s like a game with no referee!

| Component | Purpose |

|---|---|

| Bed | Base of the lathe |

| Headstock | Holds and spins the metal |

| Tailstock | Supports the metal piece |

Importance of Lathe Belts

Role of belts in metal lathe operation. Impact of belt quality on performance and output.Lathe belts play a vital role in metal lathe operation. They connect the motor to the spindle, allowing smooth rotation. If the belt is of high quality, it enhances performance. A strong belt can improve output and make tasks easier. Poor-quality belts can lead to slippage and uneven cuts. This can waste time and materials. Choosing the right belt matters for efficiency and better results.

Why are lathe belts important?

Lathe belts are crucial because they transfer power effectively. This ensures that the lathe operates smoothly.

Key roles of lathe belts:

- Connects motor and spindle.

- Ensures even movement.

- Affects cutting quality.

Selecting the Right Belt for Your Lathe

Factors to consider when choosing a lathe belt (material, size, etc.). Common mistakes to avoid in belt selection.Choosing a belt for your lathe can be tricky. You need to think about a few key factors:

- Material: Look for strong materials like rubber or polyurethane.

- Size: Make sure the belt fits your lathe perfectly.

- Type: Select the right belt type based on your specific tasks.

Avoid common mistakes like:

- Picking the wrong size. Always measure first!

- Choosing low-quality belts. They might wear out quickly.

- Ignoring wear signs. Replace belts before they break.

Taking time to choose carefully will help your lathe run well!

What should I consider when selecting a lathe belt?

You should consider the material, size, and type of the belt you need. These factors greatly affect how well your lathe works.

Installation and Maintenance of Lathe Belts

Stepbystep guide to installing a lathe belt. Tips for maintaining and troubleshooting belt issues.Installing a lathe belt is easy with these steps. First, unplug the machine. Next, remove the old belt carefully. Align the new belt with the pulleys. Make sure it fits snugly but not too tight. After that, plug the machine back in and test it.

To keep your belt in good shape, check it regularly. Look for signs of wear or cracks. If your belt slips, try adjusting the tension. Always keep the lathe clean. This helps prevent problems.

How do you troubleshoot belt issues?

To fix belt problems, check for damage regularly. If it makes noise, inspect the tension. You may need to replace it if there’s serious wear.

Tips for belt maintenance:

- Clean the lathe often

- Store belts in a cool place

- Inspect for wear every month

Common Applications of Metal Lathes

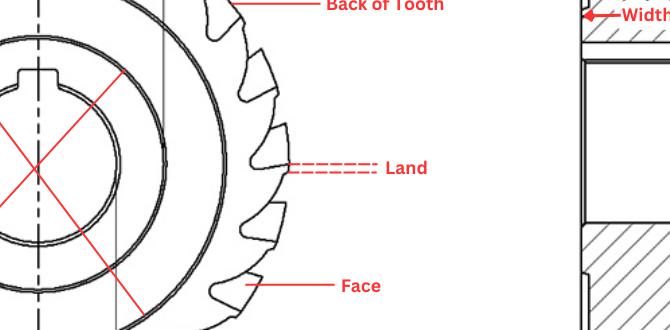

Industryspecific uses (manufacturing, prototyping, etc.). Examples of projects that can be completed with metal lathes.Metal lathes are used in many industries. They help workers shape and cut metal pieces. From factories to small workshops, these machines are crucial. Some common uses include:

- Creating parts for vehicles

- Making tools and machinery

- Building models or prototypes

- Repairing equipment

They can make projects like metal pipes, gears, and even custom furniture. With a metal lathe, you can turn a simple idea into something amazing!

What are metal lathes often used for?

Metal lathes are often used for manufacturing and prototyping. They are key in crafting precise parts.

Safety Considerations When Using Metal Lathes

Essential safety gear and precautions. Common hazards and how to mitigate them.Using a metal lathe can be fun, but safety is key! First, always wear your essential safety gear like goggles and gloves. You wouldn’t want metal shavings in your eyes, right? Now, let’s talk about common hazards. The lathe can spin really fast, which can make things—and hands—fly off if you’re not careful. Follow these tips to stay safe and keep your fingers intact.

| Hazard | Precaution |

|---|---|

| Flying debris | Wear safety goggles |

| Spinning parts | Keep loose clothing away |

| Earpiece noise | Use ear protection |

Remember, safety first! It’s better to be safe than sorry, like the time I almost lost my lunch to a flying wrench. Don’t let that be you!

Future Trends in Metal Lathe Technology

Innovations in metal lathe design and functionality. The impact of automation and smart technology on metal lathes.Metal lathes are changing fast. New designs make them easier to use. They can now perform more functions with better precision. Automation adds efficiency, letting machines run by themselves. Smart technology is a game changer. These machines can now collect data and learn from their tasks. This makes for quicker and safer work. Imagine a lathe that alerts you when it needs maintenance! Exciting changes are coming to metalworking industries.

What are the benefits of smart technology in metal lathes?

Smart technology makes metal lathes faster and safer. It also helps reduce errors. Machines get updates automatically. This means better designs and less downtime for repairs.

Key Features of Smart Metal Lathes:

- Automation for less manual work

- Data collection for improved performance

- Remote monitoring for safety

Conclusion

In summary, a lathe is essential for shaping metal. This guide teaches you how to use a metal lathe effectively. We learned about adjusting the belt and maintaining the machine. Practice these skills for better results. You can explore more resources online to deepen your knowledge. Keep experimenting, and you’ll become more confident in your lathe projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Belt Applications:Sure! Metal lathes use belts to turn materials like wood and metal into shapes. You can see these belts moving when the lathe operates. They help transfer power from the motor to the spindle, which holds the material. If a belt breaks, the machine won’t work well. It’s important to check and replace belts when needed for safe use.

Sure! Please ask your question, and I’ll provide a simple answer.

What Are The Different Types Of Belts Used In Metal Lathes, And How Do They Affect Performance?Metal lathes use different belts like V-belts and flat belts. V-belts are shaped like a triangle, helping machines grip better. Flat belts are, well, flat and are used for smoother motion. The type of belt can change how fast the lathe spins. A good belt makes the machine work better and last longer.

How Do You Determine The Correct Belt Size And Type For A Specific Metal Lathe Model?To find the right belt size and type for your metal lathe, first, check the lathe’s manual. It usually lists the belt size. If you don’t have the manual, measure the old belt if you have one. You can also measure the distance between the pulleys. Finally, take this information to a store that sells belts for help.

What Are The Common Signs Of Wear And Tear In Lathe Belts, And When Should They Be Replaced?You can tell a lathe belt is worn out if it looks cracked, frayed, or has shiny spots. If you hear a squeaking sound when the lathe runs, that could mean the belt is too loose or damaged. We should replace the belt as soon as we notice these signs. Waiting too long can cause bigger problems for the machine. Always check the belt regularly to keep everything working well!

How Can Improper Belt Tension Impact The Operation And Longevity Of A Metal Lathe?If the belt on a metal lathe is too loose or too tight, it can cause problems. A loose belt may slip, making the machine run slower or stop. A tight belt can wear out parts faster and break more easily. Both of these issues can shorten the lathe’s life and make it hard to work well. So, keeping the belt tension just right is really important!

What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe Belt?To make your metal lathe belt last longer, you should keep it clean. Wipe off dust and oil with a cloth. Check the belt for any cracks or damage regularly. Also, adjust the tension if it’s too loose or too tight. Lastly, store your lathe in a dry place to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Metal Lathe Belt Applications:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Metal lathes use belts to turn materials like wood and metal into shapes. You can see these belts moving when the lathe operates. They help transfer power from the motor to the spindle, which holds the material. If a belt breaks, the machine won’t work well. It’s important to check and replace belts when needed for safe use.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll provide a simple answer.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Belts Used In Metal Lathes, And How Do They Affect Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Metal lathes use different belts like V-belts and flat belts. V-belts are shaped like a triangle, helping machines grip better. Flat belts are, well, flat and are used for smoother motion. The type of belt can change how fast the lathe spins. A good belt makes the machine work better and last longer.”}},{“@type”: “Question”,”name”: “How Do You Determine The Correct Belt Size And Type For A Specific Metal Lathe Model?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right belt size and type for your metal lathe, first, check the lathe’s manual. It usually lists the belt size. If you don’t have the manual, measure the old belt if you have one. You can also measure the distance between the pulleys. Finally, take this information to a store that sells belts for help.”}},{“@type”: “Question”,”name”: “What Are The Common Signs Of Wear And Tear In Lathe Belts, And When Should They Be Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell a lathe belt is worn out if it looks cracked, frayed, or has shiny spots. If you hear a squeaking sound when the lathe runs, that could mean the belt is too loose or damaged. We should replace the belt as soon as we notice these signs. Waiting too long can cause bigger problems for the machine. Always check the belt regularly to keep everything working well!”}},{“@type”: “Question”,”name”: “How Can Improper Belt Tension Impact The Operation And Longevity Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the belt on a metal lathe is too loose or too tight, it can cause problems. A loose belt may slip, making the machine run slower or stop. A tight belt can wear out parts faster and break more easily. Both of these issues can shorten the lathe’s life and make it hard to work well. So, keeping the belt tension just right is really important!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Can Extend The Lifespan Of A Metal Lathe Belt?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make your metal lathe belt last longer, you should keep it clean. Wipe off dust and oil with a cloth. Check the belt for any cracks or damage regularly. Also, adjust the tension if it’s too loose or too tight. Lastly, store your lathe in a dry place to prevent rust.”}}]}