Have you ever marveled at how tools can shape metal into incredible forms? The world of metalworking is fascinating, especially when it comes to using lathes. These machines can create precise parts for many projects. Imagine transforming a simple block of metal into a beautiful vase or a crucial engine part.

Now, let’s dive into a special topic: lathe application guide for a metal lathe CNC retrofit. What does that mean, you ask? It’s all about upgrading older lathes to perform like new ones. With the right upgrades, you can boost your machine’s performance and better control your work.

Did you know that some hobbyists turn their old manual lathes into CNC machines? This retrofit process makes it easier to produce complex shapes and designs. It’s like giving your trusty old friend a shiny, high-tech makeover!

In this guide, we will explore why retrofitting a metal lathe is a smart choice. We will also share tips on how to go about it. Get ready to unlock new possibilities and skills with your lathe!

A Comprehensive Lathe Application Guide: Metal Lathe Cnc Retrofit

Lathe Application Guide for Metal Lathe CNC Retrofit

Many people wonder how to upgrade their metal lathes. A CNC retrofit can boost precision and efficiency. It turns traditional lathes into modern machines. This guide helps you understand key steps. It covers essential tools, techniques, and software needed. Have you ever thought about how a simple upgrade could save you time? With the right modifications, your lathe can perform complex tasks with ease. Investing in a CNC retrofit may change the way you work forever.Understanding Lathe Machines

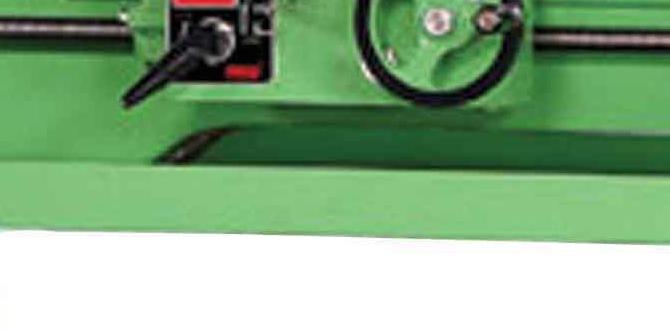

Definition and types of lathe machines used in machining. Key components of a lathe machine and their functions.Lathe machines are special tools that shape materials, like metal and wood. There are different types, such as engine lathes and CNC lathes. Each type serves a specific purpose. Key parts of a lathe include:

- Bed: The main body that supports all parts.

- Headstock: Holds the motor and drives the spindle.

- Tailstock: Supports the other end of the workpiece.

- Tool Rest: Holds the cutting tools in place.

Together, these parts work to create precise shapes. Understanding how they function helps users operate lathes safely and effectively.

What types of lathe machines are used in machining?

Common types include manual lathes and CNC lathes. Manual lathes need hands-on operation, while CNC lathes are computer-controlled, allowing for automatic and precise work.

Benefits of CNC Retrofit for Metal Lathes

Advantages of upgrading to CNC technology. Costeffectiveness of retrofitting versus buying new machines.Upgrading to CNC technology offers many benefits for metal lathes. First, it boosts accuracy and speed. That means better results in less time. Second, retrofitting is often cheaper than buying brand new machines. Why replace when you can improve what you already have? This can save you money and still give great performance.

- High precision: CNC machines create detailed designs.

- Time-saving: They work faster than traditional lathes.

- Lower cost: Retrofitting can cost less than new equipment.

Key Features of CNC Retrofits

Essential components in a CNC retrofit kit. Differences between standard and advanced CNC features.CNC retrofit kits come packed with some neat features! The basic components usually include a new controller, motors, and a power supply. Think of it like giving your old car a shiny engine upgrade. Standard features let you control your lathe, while advanced options, like automated tool changing, make you feel like a wizard in a machine shop! Let’s break it down:

| Standard Features | Advanced Features |

|---|---|

| User-friendly display | Auto tool changers |

| Basic movement control | Predictive maintenance alerts |

| Simple programming | Real-time monitoring |

With these essential features, your metal lathe will transform into a powerhouse! After all, who wouldn’t want a machine that does half the work for you?

Step-by-Step Guide to Retrofitting a Metal Lathe

Preparing your workstation and workspace considerations. Detailed retrofitting process from disassembly to calibration.Before diving into the retrofitting adventure, let’s set up our workplace. A clean, organized space is key! Make sure your desk has room for tools and spare parts. Remember, you don’t want to trip over a wrench while holding a saw!

Next, let’s get your metal lathe ready. Start with disassembly. Carefully remove individual components and keep track of each piece. It’s like a puzzle; losing one piece means a lot of frustration later!

| Step | Action |

|---|---|

| 1 | Clear your workspace. |

| 2 | Disassemble the lathe carefully. |

| 3 | Update or replace parts as needed. |

| 4 | Reassemble the lathe, checking each part. |

| 5 | Calibrate for accuracy. |

Once it’s all back together, don’t forget the calibration. It’s like adjusting your glasses – you want everything to be clear. With this guide, your lathe will be ready for action!

Common Challenges in CNC Retrofitting

Identifying potential problems during the retrofit process. Solutions to common retrofit issues and troubleshooting tips.CNC retrofitting can feel like solving a tricky puzzle, but don’t worry! First, test for wiring issues before you connect everything. Many find that loose wires give them a fit! Next, check the software compatibility; sometimes a little upgrade does wonders. If gears are grinding, it’s not broken—just too tight! Adjust them, and voilà! Remember, retrofitting is like making pizza: add the right toppings, and you’ll have a masterpiece!

| Common Issues | Solutions |

|---|---|

| Poor Wiring | Ensure all connections are tight |

| Software Conflicts | Update or replace software |

| Tight Gears | Loosen the adjustment until smooth |

Choosing the Right CNC Retrofit Kit

Factors to consider when selecting a retrofit kit. Comparison of popular CNC retrofit kits in the market.Choosing a CNC retrofit kit is exciting but tricky, like finding the right candy in a big jar! First, think about compatibility. Make sure the kit fits your lathe model. Next, consider ease of installation. Some kits need fancy tools; others are as easy as pie. Don’t forget to check customer reviews; they’re like gold! Finally, look at cost versus features. A small price tag does not always mean a small performance.

| Retrofit Kit | Compatibility | Installation Ease | Price |

|---|---|---|---|

| Kit A | High | Easy | $$$ |

| Kit B | Medium | Moderate | $$ |

| Kit C | High | Very Easy | $$$$ |

In the end, be a wise shopper. You want a kit that fits your needs and makes your lathe sing like a choir!

Maintenance and Upkeep of Retrofitted CNC Lathes

Regular maintenance practices for longevity and performance. Monitoring software updates and hardware improvements.Keeping your retrofitted CNC lathe in tip-top shape is like taking care of a pet—it’s all about regular check-ups and a few treats! Start with regular cleaning to keep out dust and debris. This helps it run smoothly and last longer. Don’t forget to check the software updates. New versions can boost performance, like giving your lathe a double shot of espresso! And keep an eye on hardware upgrades too, as they can turn your machine into a super-lathe. Here’s a handy table to track your maintenance schedule:

| Maintenance Task | Frequency |

|---|---|

| Clean machine | Weekly |

| Check software updates | Monthly |

| Inspect hardware | Quarterly |

Case Studies: Successful CNC Retrofits

Reallife examples of businesses that benefited from CNC retrofitting. Lessons learned from successful retrofit projects.Many businesses have found great success by upgrading their machines. For example, a small tool shop switched to a CNC retrofit and saw production speeds increase by 40%. They joked it felt like getting a turbo boost on a bicycle! Lessons learned from these projects include the importance of planning and training staff. Proper setup and education ensure smooth sailing and reduce hiccups down the road.

| Business Case | Benefit | Lesson Learned |

|---|---|---|

| Small Tool Shop | 40% faster production | Importance of training |

| Manufacturing Firm | 10% cost savings | Thorough planning is key |

| Local Workshop | Higher accuracy | Test thoroughly before full use |

These examples show how a CNC retrofit can be a game-changer, making shops faster and smarter. Remember, every upgrade should feel like a win, not an uphill battle!

Future Trends in Lathe Technology

Upcoming advancements in CNC retrofitting technology. The evolving role of automation in metal lathe applications.Exciting changes are happening in lathe technology. CNC retrofitting will improve how machines work. New tools will help machines cut better and faster. Automation is also becoming very important. It helps machines work without much help from people. This makes them efficient and precise. Here are some advances to look out for:

- Smarter software for better programming.

- More robotic helpers for tasks.

- Improved materials for durability.

These trends will make metal lathes more helpful and easy to use.

What is the future of CNC retrofitting?

The future of CNC retrofitting is bright. Machines will become faster and smarter. New tools will make lathes easier to work with.

Conclusion

In conclusion, a lathe application guide helps you understand metal lathes and CNC retrofits. You learn about tools, techniques, and setups. By upgrading to CNC, you improve accuracy and efficiency. We encourage you to explore more resources and try simple projects. With practice, you can master these skills and create amazing designs. Get started today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Application Guide For Metal Lathe Cnc Retrofit:Sure! When you want to change a metal lathe to use CNC, or Computer Numerical Control, it helps a lot. First, you will need to find the right parts to fit your machine. Then, you can follow steps in a guide to make the changes. It’s like building with blocks; you just need to stack them in the right way. With practice, you can make your lathe work exactly as you want!

Sure! Just ask your question, and I’ll be happy to help you with a short answer.

What Are The Essential Components Needed For Retrofitting A Traditional Metal Lathe To Cnc Capabilities?To turn a regular metal lathe into a CNC lathe, you need a few important parts. First, you’ll need a computer or controller to run the machine. Next, add stepper motors to move the lathe’s tools. You also need a power supply to keep everything running. Lastly, install software that tells the lathe what to do.

How Do You Determine The Compatibility Of A Cnc Control System With An Existing Metal Lathe?To check if a CNC (Computer Numerical Control) system works with a metal lathe, you need to look at a few things. First, check the size and shape of your lathe. Next, see if the CNC system can connect to it correctly. Then, make sure they both use similar types of software. Finally, ask experts or read reviews to learn how well they work together.

What Are The Common Challenges Faced During The Cnc Retrofitting Process Of A Metal Lathe?When we change a metal lathe to be controlled by a computer (CNC), we can face some problems. First, making sure all the parts fit together correctly can be tricky. We also need to set up the computer software, which might be confusing. Sometimes, finding the right tools and pieces can be hard. Lastly, learning to use the new system takes time and practice.

How Can Software Differences Affect The Performance And Functionality Of A Retrofitted Cnc Metal Lathe?Software differences can change how well a retrofitted CNC (Computer Numerical Control) metal lathe works. Some software can make the machine run faster or more smoothly. Other programs might not use the lathe’s full power. If we use good software, we can create better pieces of metal. So, the right software helps us do a better job!

What Types Of Projects Or Applications Are Best Suited For A Cnc Retrofitted Metal Lathe, And How Can That Influence The Retrofit Design?A CNC retrofitted metal lathe works great for making parts like gears, wheels, or custom tools. It helps us create precise shapes and sizes. If we want to make small things quickly, we need a design that supports fast movement. For bigger projects, we need a stronger base. Choosing the right materials for our retrofit can really help with what we want to make.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Application Guide For Metal Lathe Cnc Retrofit:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When you want to change a metal lathe to use CNC, or Computer Numerical Control, it helps a lot. First, you will need to find the right parts to fit your machine. Then, you can follow steps in a guide to make the changes. It’s like building with blocks; you just need to stack them in the right way. With practice, you can make your lathe work exactly as you want!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just ask your question, and I’ll be happy to help you with a short answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Components Needed For Retrofitting A Traditional Metal Lathe To Cnc Capabilities?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To turn a regular metal lathe into a CNC lathe, you need a few important parts. First, you’ll need a computer or controller to run the machine. Next, add stepper motors to move the lathe’s tools. You also need a power supply to keep everything running. Lastly, install software that tells the lathe what to do.”}},{“@type”: “Question”,”name”: “How Do You Determine The Compatibility Of A Cnc Control System With An Existing Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check if a CNC (Computer Numerical Control) system works with a metal lathe, you need to look at a few things. First, check the size and shape of your lathe. Next, see if the CNC system can connect to it correctly. Then, make sure they both use similar types of software. Finally, ask experts or read reviews to learn how well they work together.”}},{“@type”: “Question”,”name”: “What Are The Common Challenges Faced During The Cnc Retrofitting Process Of A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When we change a metal lathe to be controlled by a computer (CNC), we can face some problems. First, making sure all the parts fit together correctly can be tricky. We also need to set up the computer software, which might be confusing. Sometimes, finding the right tools and pieces can be hard. Lastly, learning to use the new system takes time and practice.”}},{“@type”: “Question”,”name”: “How Can Software Differences Affect The Performance And Functionality Of A Retrofitted Cnc Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Software differences can change how well a retrofitted CNC (Computer Numerical Control) metal lathe works. Some software can make the machine run faster or more smoothly. Other programs might not use the lathe’s full power. If we use good software, we can create better pieces of metal. So, the right software helps us do a better job!”}},{“@type”: “Question”,”name”: “What Types Of Projects Or Applications Are Best Suited For A Cnc Retrofitted Metal Lathe, And How Can That Influence The Retrofit Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A CNC retrofitted metal lathe works great for making parts like gears, wheels, or custom tools. It helps us create precise shapes and sizes. If we want to make small things quickly, we need a design that supports fast movement. For bigger projects, we need a stronger base. Choosing the right materials for our retrofit can really help with what we want to make.”}}]}