Have you ever wondered how a simple piece of metal can be turned into a work of art? Using a lathe makes this magic happen. With the right lathe application guide, anyone can learn this skill.

Imagine standing in a workshop, surrounded by machines. The hum of the lathe fills the air. You can adjust the metal lathe control panel to create designs just by turning a dial. It’s like having a superpower!

Lathe machines can transform raw metal into stunning shapes. From parts for toys to tools for your home, the possibilities are endless. Do you want to learn how to use one? A good guide can help you master the control panel and unleash your creativity.

So, let’s dive in! We will explore how lathe machines work and how you can take charge of your projects. Get ready to discover the amazing world of metalworking!

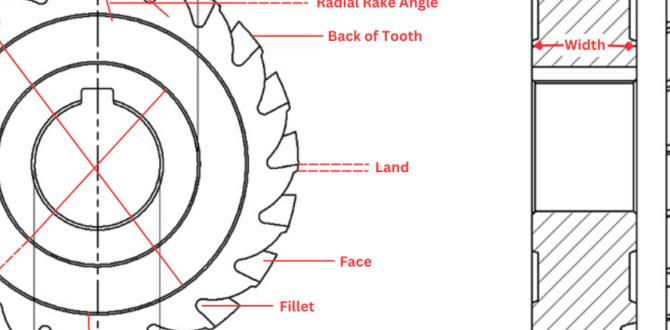

Lathe Application Guide: Metal Lathe Control Panel Explained Introduction To Metal Lathe Control Panels A Metal Lathe Control Panel Is An Essential Component For Operating A Lathe Machine Effectively. This Guide Will Explore Various Lathe Applications, Focusing On The Role And Functionality Of The Control Panel, Ensuring Users Can Enhance Their Machining Processes. Understanding Metal Lathes Metal Lathes Are Versatile Machines Used For Shaping Metal And Creating Precise Components. They Operate By Rotating The Workpiece Against Cutting Tools, Allowing For Various Operations Such As Turning, Drilling, And Threading. The Role Of The Control Panel The Control Panel Is The Command Center For The Metal Lathe. It Houses Essential Controls That Allow Operators To Adjust Settings, Monitor The Machine’S Performance, And Manage Cutting Speeds. A User-Friendly Control Panel Can Significantly Increase Efficiency And Accuracy In Machining Tasks. Key Features Of A Metal Lathe Control Panel 1. **Speed Control**: Allows For The Adjustment Of Spindle Speeds To Suit Different Materials And Cutting Tools. 2. **Feed Rate Adjustments**: Operators Can Modify The Feed Rates To Manage How The Tool Interacts With The Workpiece, Impacting Surface Finish And Machining Time. 3. **Tool Positioning**: Precise Controls For Tool Positioning Ensure Accurate Cutting Depths And Angles. 4. **Emergency Stop**: Safety Is Paramount; An Emergency Stop Feature Is Crucial For Immediate Halting Of The Machine In Case Of Malfunction Or Danger. Common Applications Of Metal Lathes – **Manufacturing**: Creating Parts For Machinery, Automotive, And Aerospace Applications. – **Prototype Development**: Designing And Prototyping New Concepts With Precision Machining. – **Repair Services**: Fabrication Of Replacement Parts For Machinery Or Equipment. Tips For Using A Metal Lathe Control Panel – **Familiarize Yourself With The Controls**: Before Operating A Metal Lathe, Take The Time To Understand The Control Panel’S Layout And Functions. – **Start With Recommended Settings**: Use Default Settings Based On The Material Being Worked On, Then Make Adjustments As Necessary Based On Your Observations. – **Regular Maintenance And Calibration**: Keep The Control Panel And Machine Well-Maintained For Optimal Performance And Accuracy. Conclusion Understanding The Metal Lathe Control Panel And Its Applications Can Greatly Enhance Machining Operations. By Familiarizing Oneself With Its Features And Functionalities, Users Can Optimize Their Machining Processes, Leading To Better Performance And Finished Product Quality. Whether You Are A Beginner Or An Experienced Machinist, A Solid Grasp Of Lathe Operation Is Essential For Success In Metalworking.

Lathe Application Guide: Metal Lathe Control Panel

Using a metal lathe requires understanding its control panel. Each button and knob serves a purpose. For example, the speed control adjusts how fast the lathe spins. This is key for different materials. Did you know that adjusting the feed rate can change the smoothness of the cut? Experimenting with settings helps perfect your skills. By familiarizing yourself with the control panel, you can make precise cuts and create amazing projects. Get ready to explore the world of metalworking!Key Functions of the Control Panel

Detailed explanation of essential functions (speed control, feed rates, etc.). How each function affects machining processes.The control panel is like the captain of a ship. It keeps everything under control. One key function is speed control. It allows users to adjust how fast the lathe spins, making it easier for different materials. Another important feature is feed rates. This controls how quickly the tool moves into the material. Choosing the right speed and feed can make your project smoother and more efficient. If you go too fast, you might end up with a mess—like trying to eat soup with a fork!

| Function | Purpose |

|---|---|

| Speed Control | Adjusts spinning speed of lathe. |

| Feed Rates | Controls how fast tool advances into material. |

Setup and Configuration of the Control Panel

Stepbystep guide to initial setup. Common configuration settings and their purposes.To start with the control panel setup, follow these simple steps. First, connect the panel to a power source. Next, ensure the lathe is securely fitted. Adjust the emergency stop button. Then, set the display language. Finally, ensure all connections are tight for safety.

Common settings include:

- Spindle Speed – Controls how fast the lathe spins.

- Feed Rate – This sets how quickly the tool moves.

- Tool Positioning – Helps in fine-tuning the tool location.

What are key features in the control panel?

Key features include user-friendly displays and safety controls that enhance operation.

Understanding these steps makes using the control panel easy and safe. You’ll feel confident as you learn what each setting does. Happy machining!

Troubleshooting Common Issues

Compilation of frequently encountered problems. Efficient troubleshooting steps for control panel issues.Fixing control panel issues can sometimes feel like solving a puzzle, but fear not! Here are some common problems you might face and how to tackle them. First, let’s look at a list of frequent annoyances:

| Problem | Solution |

|---|---|

| Power not working | Check the power source and cables. |

| Display malfunction | Reset the control panel. |

| Unexpected stops | Inspect for loose connections. |

If your lapses still need fixing, try these steps: Ensure all buttons are clicked firmly, not just giving them a polite tap! And remember, sometimes the magic lies in the simplest fixes. A little dust can do big damage, so clean that panel regularly!

Maintenance and Upkeep of Your Control Panel

Routine maintenance tasks to ensure longevity. Signs that indicate potential control panel failures.Keeping your control panel happy is essential for it to work well. Regular check-ups help avoid problems down the line. Think of it like giving your lathe a spa day! Check connections, wipe dust, and look for loose wires. If things start to smell funny or buttons stick, it’s time to worry. Ignoring signs of trouble is like letting a cat near a fish bowl!

| Routine Maintenance Tasks | Signs of Potential Failures |

|---|---|

| Inspect wires monthly | Burning smell |

| Clean dust weekly | Sticky buttons |

| Check connections regularly | Random shutdowns |

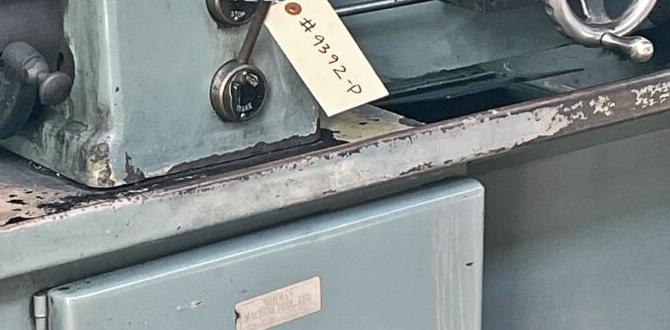

Comparing Different Metal Lathe Control Panels

Review of popular control panels on the market. Pros and cons of various options for different machining needs.Several metal lathe control panels on the market can suit different machining needs. Some popular options are packed with features, while others are simple and user-friendly. Each control panel has its own pros and cons, depending on how you plan to work.

- Digital Control Panels: Offer precise settings. Easy to read.

- Manual Control Panels: Simple to use. More control for skilled users.

- Hybrid Panels: Balance between manual and digital. Versatile for many tasks.

Choosing the right panel makes a big difference. Think about what you need before you buy!

What features should you look for in a metal lathe control panel?

Look for features like ease of use, flexibility, and accuracy. You want something that fits your skill level and tasks.

Best Practices for Effective Machining with the Control Panel

Tips for optimizing performance and precision. Techniques to enhance productivity during operation.To get the best results from your metal lathe control panel, follow these simple tips. Start by regularly maintaining your machine. Clean it often to keep it running smoothly. Adjust the settings carefully for different tasks to improve precision. Use the right speed and feed rates for your materials. This can make a big difference. To boost productivity, organize your workspace and keep tools handy. Plan your projects to save time and avoid mistakes.

| Tip | Benefit |

|---|---|

| Maintain regularly | Better performance |

| Adjust settings | Increased precision |

| Organize workspace | Enhanced productivity |

How can I improve my machining skills?

You can enhance your machining skills by practicing regularly and learning from experts. Consider taking courses on metalworking to learn new techniques.Conclusion

In this guide, we explored the metal lathe control panel, highlighting its key features and functions. You learned how to operate it safely and efficiently. Understanding each control helps you make precise adjustments. Now, practice on your lathe and refer back to this guide for tips. Keep learning to improve your skills and enjoy your metalworking projects!FAQs

What Are The Key Components Of A Metal Lathe Control Panel And Their Functions?A metal lathe control panel has a few key parts. First, there’s the power button to turn the machine on and off. Then, we have speed controls to change how fast the lathe spins. There’s also a feed control that helps move the tool along the metal. Finally, a stop button allows you to quickly stop the machine.

How Can I Troubleshoot Common Issues Encountered With A Lathe Control Panel?To troubleshoot issues with a lathe control panel, start by checking the power. Make sure the lathe is plugged in and turned on. Next, look for any loose wires or connections. If the display is blank, restart the machine. Finally, consult the manual for error codes to understand possible problems.

What Safety Features Should Be Included In A Metal Lathe Control Panel To Ensure Operator Protection?A metal lathe control panel should have safety features to protect you while you work. First, there should be an emergency stop button. This lets you quickly turn off the machine if something goes wrong. There should also be clear warning lights or alarms to alert you when it’s dangerous. Finally, the panel should have a guard to keep your hands and clothes away from moving parts.

How Can The Control Panel Be Configured To Optimize Machining Precision And Efficiency?You can make the control panel better for machining by adjusting a few settings. First, set the right speed for the machine to match the job. Then, choose the right tools and materials to avoid mistakes. Lastly, keep everything clean and check regularly to catch problems early. This way, we can make sure everything runs smoothly and accurately!

What Are The Best Practices For Maintaining And Calibrating The Lathe Control Panel For Consistent Performance?To keep the lathe control panel working well, you should regularly check the buttons and switches. Clean it gently to remove dust or dirt. If you notice any problems, fix them right away. We should also check the settings to make sure they are correct. By doing this, we help the lathe work better and last longer.