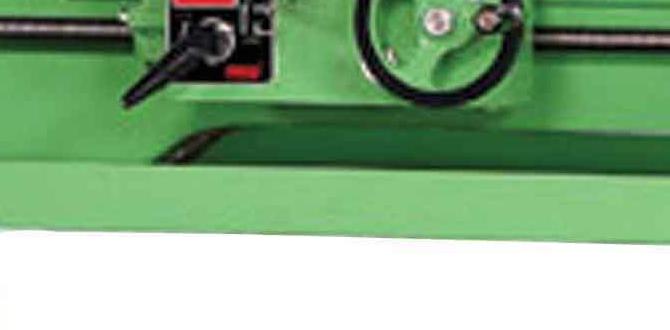

Metal lathes are powerful tools that can shape and cut metal with precision. Imagine making a custom part for your project right in your garage! Have you ever wondered how these machines work?

This is where our lathe application guide comes in. It will help you understand how a metal lathe spindle plays a key role in this process. A spindle is like the heart of the lathe. It holds the tools in place and allows them to spin.

Using a metal lathe can be exciting. You can create anything from small gears to large doorknobs. The possibilities are nearly endless. Every craftsman starts somewhere. Reading about lathe applications can give you a head start.

So, are you ready to dive into the world of lathes? Let’s explore how you can use a metal lathe spindle to bring your ideas to life!

Comprehensive Lathe Application Guide: Metal Lathe Spindle Insights

Lathe Application Guide for Metal Lathe Spindles

Using a metal lathe spindle can be exciting. Did you know it helps shape metal into precise parts? This guide explains different spindle applications. You’ll learn how to choose the right spindle for your project. It covers factors like size, speed, and material. Discover tips for setup and care to extend spindle life. Engaging with these details can make your machining experiences smoother and more efficient. Wouldn’t that be great?Understanding Metal Lathe Spindles

Definition and function of a lathe spindle. Importance of spindle design in lathe performance.A lathe spindle is a central part of a lathe machine. It rotates the workpiece, helping shape it accurately. The spindle’s design is crucial for smooth operations and better performance. A well-made spindle enhances speed and precision, making work easier. Without a good spindle, tasks can become difficult and messy. Imagine trying to cut dough with a dull knife; the same happens with a lathe if the spindle isn’t right.

What is the function of a lathe spindle?

The lathe spindle’s main function is to hold and rotate the material being worked on. This helps in shaping, cutting, and finishing the piece effectively. A strong spindle ensures the material stays in place while you work.

Why is spindle design important?

- Performance: A good design improves the lathe’s speed and accuracy.

- Durability: Stronger materials increase the spindle’s lifespan.

- Stability: A well-designed spindle reduces vibrations, leading to cleaner cuts.

Key Features of Metal Lathe Spindles

Spindle speed and its impact on machining. Material and construction considerations for durability.Metal lathe spindles play an essential role in crafting precision parts. One important feature is spindle speed. Faster speeds allow for smoother cuts, which can save time and make the process easier. Yet, watch out! Too much speed can be like a kid with too much candy—things can get messy!

Also, consider the materials. Tougher materials in spindle construction lead to greater durability. Think of it as a knight’s armor for your lathe—it protects against wear and tear.

| Feature | Impact |

|---|---|

| Spindle Speed | Affects cutting efficiency and surface finish. |

| Material | Stronger materials enhance longevity. |

So, choosing the right spindle can mean the difference between a well-made part and a total disaster!

How to Choose the Right Metal Lathe Spindle

Factors to consider in spindle selection (e.g., application, material). Tips for evaluating spindle performance and compatibility.Choosing the right spindle for your metal lathe can feel like looking for a needle in a haystack. First, think about your application and the material you will work with. For strong materials, go for spindles with more power. Next, check the spindle’s performance and how well it matches your lathe. A good rule is to see if the spindle fits snugly; too loose might mean trouble! Use the table below for a quick comparison of spindle types.

| Spindle Type | Best For | Key Feature |

|---|---|---|

| High-Speed | Thin Materials | Fast rotation |

| Torque Spindle | Thick Metals | High power |

| Variable Speed | Multiple Uses | Adjustable |

Maintenance and Care for Lathe Spindles

Essential maintenance practices to extend spindle life. Common issues and troubleshooting techniques.Keeping lathe spindles happy is key to a long life! First, check the lubrication regularly. It’s like applying sunscreen: protect them from wear and tear! Clean the spindles often to avoid dust buildup. Watch out for weird noises—like your cat when it gets caught in a box—these can mean trouble. If your spindle isn’t spinning smoothly, it might need a check-up from a pro. Remember, a well-cared spindle is a happy spindle!

| Common Issues | Troubleshooting Tips |

|---|---|

| Unusual noises | Check for loose parts and lubricate |

| Vibration | Inspect for balance and alignment |

| Overheating | Ensure proper cooling and lubrication |

Innovations and Technologies in Metal Lathe Spindles

Emerging trends in spindle technology. Impact of CNC technology on spindle performance.New technology helps metal lathe spindles work better. One emerging trend is high-speed spindles. These spindles make jobs faster and help create precise shapes. Another big change is CNC technology. This computer-controlled system improves spindle accuracy and performance. It allows for better speed and consistency in turning metal. As machines get smarter, spindles will keep evolving.

How does CNC technology affect spindle performance?

CNC technology boosts spindle performance by enhancing speed and precision. It allows for automated programming, which means less human error. This gives smoother operations and better quality products. As a result, manufacturers can produce more items quickly and accurately.

Safety Precautions When Using Metal Lathe Spindles

Key safety measures to implement during lathe operation. Personal protective equipment (PPE) and workspace safety tips.Using metal lathe spindles can be fun, but safety comes first. Correct measures help prevent accidents.

Here are some key safety tips:

- Wear proper personal protective equipment (PPE), like gloves and goggles.

- Keep hair tied back and remove loose clothing.

- Ensure your workspace is clean and free of clutter.

- Always use a guard on the lathe.

- Make sure tools and materials are secure before starting.

Following these steps helps keep you safe while enjoying your work!

What is personal protective equipment (PPE) in metal lathe operation?

Personal protective equipment (PPE) includes gloves, goggles, and ear protection to keep you safe while working with machines.

What workspace tips should I follow?

- Keep your area tidy.

- Ensure good lighting.

- Have an emergency stop nearby.

Resources for Further Learning on Metal Lathe Spindles

Recommended books, websites, and forums for deepening knowledge. Professional organizations and training programs available.Exploring more about metal lathe spindles can be fun! Here are some great resources:

- Books: “Lathework: A Complete Guide” offers clear step-by-step instructions.

- Websites: Check out the online hub “MetalLathes.com” for tutorials and tips.

- Forums: Join “Machinist Forum” to ask questions and share ideas.

- Professional Organizations: The National Institute for Metalworking Skills (NIMS) is great for certifications.

- Training Programs: Look for local community colleges that offer metalworking courses.

These resources help you learn and grow your skills in metal lathe work!

What are some good books on metal lathe spindles?

Books like “Lathework: A Complete Guide” and “The Metalworker’s Guide” are excellent starts. They break down complex topics into simple, easy-to-follow steps.

Conclusion

In summary, understanding the metal lathe spindle is essential for successful lathe projects. You can adjust speed and torque for better results. Remember to choose the right tools and follow safety guidelines. Explore more lathe application guides to improve your skills. By practicing, you’ll create amazing projects and feel confident using a lathe. Happy turning!FAQs

Here Are Five Related Questions On The Topic Of Metal Lathe Spindle Applications:Sure! A metal lathe is a machine used to shape metal. The spindle is a part that spins the metal piece. You can use a lathe to make things like tools, car parts, or even toys. It helps us create smooth and round shapes. With a lathe, you can make a lot of cool stuff!

Sure! Please provide the question you’d like me to answer.

What Are The Key Factors To Consider When Selecting A Spindle For A Metal Lathe?When picking a spindle for a metal lathe, you need to think about a few things. First, check the spindle size to make sure it fits your lathe. Next, consider the speed of the spindle, as different jobs need different speeds. You should also think about the power, which helps the tool cut better. Lastly, make sure it is durable so it lasts a long time.

How Does Spindle Speed Influence The Machining Process On A Metal Lathe?Spindle speed is how fast the lathe spins the metal. If you go slow, you cut more carefully, but it takes longer. If you go fast, you can finish quicker, but it’s easier to make mistakes. The right speed helps us get a smooth finish and keep the tools from wearing out too fast. So, picking the right speed is important for good work!

What Are The Common Types Of Spindles Used In Metal Lathes And Their Specific Applications?Common types of spindles in metal lathes include plain spindles and geared spindles. Plain spindles are simple and good for easy jobs. They help to spin pieces of metal quickly. Geared spindles have gears that make them better for harder jobs, like cutting tough metals. We use these spindles depending on what we need to do.

How Can Proper Spindle Alignment Affect The Quality Of Workpieces Produced On A Metal Lathe?Proper spindle alignment makes sure the tool and workpiece are in the right spot. This helps cut evenly and smoothly. If the spindle is off, your pieces can end up crooked or rough. Good alignment means better quality workpieces. You’ll be proud of what you make!

What Maintenance Practices Should Be Implemented To Ensure The Longevity And Performance Of A Lathe Spindle?To keep a lathe spindle working well, you should clean it regularly. Remove dust and dirt from the parts. You also need to check the oil levels and add oil to keep things smooth. Make sure everything is tight and not loose. Finally, look for any signs of wear and fix them right away.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Metal Lathe Spindle Applications:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A metal lathe is a machine used to shape metal. The spindle is a part that spins the metal piece. You can use a lathe to make things like tools, car parts, or even toys. It helps us create smooth and round shapes. With a lathe, you can make a lot of cool stuff!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Factors To Consider When Selecting A Spindle For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a spindle for a metal lathe, you need to think about a few things. First, check the spindle size to make sure it fits your lathe. Next, consider the speed of the spindle, as different jobs need different speeds. You should also think about the power, which helps the tool cut better. Lastly, make sure it is durable so it lasts a long time.”}},{“@type”: “Question”,”name”: “How Does Spindle Speed Influence The Machining Process On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Spindle speed is how fast the lathe spins the metal. If you go slow, you cut more carefully, but it takes longer. If you go fast, you can finish quicker, but it’s easier to make mistakes. The right speed helps us get a smooth finish and keep the tools from wearing out too fast. So, picking the right speed is important for good work!”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Spindles Used In Metal Lathes And Their Specific Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common types of spindles in metal lathes include plain spindles and geared spindles. Plain spindles are simple and good for easy jobs. They help to spin pieces of metal quickly. Geared spindles have gears that make them better for harder jobs, like cutting tough metals. We use these spindles depending on what we need to do.”}},{“@type”: “Question”,”name”: “How Can Proper Spindle Alignment Affect The Quality Of Workpieces Produced On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Proper spindle alignment makes sure the tool and workpiece are in the right spot. This helps cut evenly and smoothly. If the spindle is off, your pieces can end up crooked or rough. Good alignment means better quality workpieces. You’ll be proud of what you make!”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Implemented To Ensure The Longevity And Performance Of A Lathe Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a lathe spindle working well, you should clean it regularly. Remove dust and dirt from the parts. You also need to check the oil levels and add oil to keep things smooth. Make sure everything is tight and not loose. Finally, look for any signs of wear and fix them right away.”}}]}