Have you ever wondered how to make perfect cuts with a metal lathe? The secret often lies in the tailstock alignment. A well-aligned tailstock can make your work easier and your projects more precise. Many people overlook this important step. But did you know that proper alignment can save you time and materials?

In this lathe application guide, we will explore how to align the tailstock of your metal lathe. Anyone can do it, regardless of skill level. Imagine creating perfect cylinders or neat holes on your first try. Doesn’t that sound exciting?

Let’s dive into some simple steps that can help you get the best results. With the right adjustments, you’ll notice a big difference in your projects. So, gear up and prepare to discover the best practices for tailstock alignment!

Lathe Application Guide: Metal Lathe Tailstock Alignment

Lathe Application Guide: Metal Lathe Tailstock Alignment

Proper alignment of the tailstock on a metal lathe is crucial for accuracy. Misalignment can lead to uneven cuts and wasted materials. Start by checking the tailstock against the lathe bed. A simple adjustment ensures everything lines up perfectly. Did you know that even a slight misalignment can create major issues in your project? By mastering these alignment techniques, you’ll improve your machining skills and enjoy better outcomes in your work.Importance of Tailstock Alignment

Explanation of how tailstock misalignment affects machining quality. Common issues caused by improper tailstock alignment.Proper tailstock alignment is crucial for good machining. If the tailstock is misaligned, it can lead to several problems. Your metal workpiece may not be shaped correctly, and it might wobble during cutting. This can cause:

- Poor surface finish

- Inaccurate dimensions

- Increased tool wear

- Risk of damaging the workpiece

Even a small misalignment can ruin your project. Always check alignment for the best results!

What happens if the tailstock is misaligned?

If the tailstock is misaligned, your machining quality suffers. You may face issues like uneven surface finishes, incorrect sizing, and faster wear on your tools.

Tools Required for Tailstock Alignment

List of essential tools for aligning the tailstock. Description of measuring tools and their functions.To align the tailstock on your metal lathe, you’ll need a few essential tools. These tools will help you measure and adjust the tailstock easily. Here’s a quick list:

- Caliper: Measures diameter and thickness accurately.

- Dial Indicator: Checks for precision in alignment.

- Tape Measure: Quickly measures longer distances.

- Wrench Set: Helps to tighten or loosen parts.

Using the right tools makes aligning the tailstock easier. This way, your lathe will work better, and you can create amazing projects!

What tools do I need for tailstock alignment?

You will require a caliper, dial indicator, tape measure, and a wrench set for effective tailstock alignment. These tools ensure accurate measurements for a smooth operation.

Step-by-Step Tailstock Alignment Procedure

Detailed instructions for aligning the tailstock. Key points to consider during the alignment process.Aligning the tailstock correctly is important for accurate machining. Follow these simple steps for alignment:

- Check the tailstock position. It should sit against the bed.

- Use a dial indicator for precise measurement.

- Adjust the tailstock sideways as needed.

- Lock it in place once aligned.

- Test with a piece of material for accuracy.

Key points to remember:

- Always double-check your measurements.

- Make small adjustments at a time.

- Inspect regularly for wear and tear.

Proper alignment boosts the quality of your work. Don’t skip this step!

Why is tailstock alignment important?

Tailstock alignment ensures the tool cuts accurately. Without proper alignment, your projects may have mistakes. This affects the entire machining process.

Maintaining Tailstock Alignment

Regular maintenance practices for preserving alignment. Recommended inspection frequency for optimal performance.To keep your tool working well, check the tailstock alignment often. Regular checks help prevent problems. A simple way to keep it aligned is by doing a test cut. This shows if everything is straight. Make sure to inspect every few weeks for the best results. Here are some quick tips:

- Use a dial gauge for precise measurements.

- Look for wear or damage regularly.

- Clean the tailstock and rails to avoid dirt buildup.

How often should you inspect the tailstock?

Inspect the tailstock every 2-4 weeks for optimal performance.

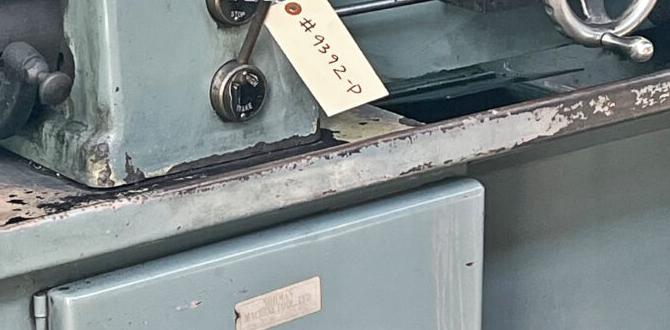

Troubleshooting Tailstock Alignment Issues

Symptoms of misalignment and their diagnostic steps. Solutions to rectify alignment problems in practice.Misalignment of the tailstock can cause big headaches. If your projects show more wobble than a dancing clown, it’s time to check your alignment! Common signs include uneven diameters on cuts and an awkward fitment of tools. To diagnose, start by measuring the distance between the tailstock and the spindle. If they don’t match, your tailstock needs a tweak.

Here’s a simple table to guide you through fixing common alignment issues:

| Symptom | Diagnosis | Solution |

|---|---|---|

| Wobbly cuts | Check if the tailstock is level | Adjust the tailstock until level |

| Tool not fitting | Measure distance from tailstock to spindle | Reposition the tailstock as needed |

By correcting these issues, your lathe will perform like a champ! Remember, a happy lathe makes for happy projects.

Conclusion

In summary, correctly aligning the tailstock on a metal lathe is crucial for accurate machining. You should regularly check its position to avoid issues like tapering. Remember to use proper tools for alignment and practice these steps for improvement. For deeper understanding, consider reading more about lathe setup and techniques. Let’s keep learning and making better projects together!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Application Guide For Metal Lathe Tailstock Alignment:Sure! When using a metal lathe, the tailstock helps keep the workpiece steady. We need to make sure it’s lined up with the main part of the lathe. If it’s not straight, it can make parts uneven. To check alignment, you can use a special tool, called a dial indicator. Always take your time to get it right!

Sure! Please provide the question you want me to answer.

What Are The Common Signs That Indicate A Misaligned Tailstock On A Metal Lathe?If the tailstock on a metal lathe is misaligned, you might notice a few things. The parts you make could be uneven or out of shape. You may see a wobble when the machine is running. Sometimes, the tool won’t cut straight. Checking these signs helps us fix the problem quickly.

How Can You Accurately Measure Tailstock Alignment In A Metal Lathe Setup?To check tailstock alignment on a metal lathe, you can use a tool called a dial indicator. First, place the dial indicator on the lathe bed and set it against the tailstock. Then, slide the tailstock along the lathe and watch the dial. If the needle stays still, the tailstock is aligned. If it moves, you may need to adjust the tailstock until it’s straight.

What Tools Are Recommended For Adjusting The Tailstock To Ensure It Is Parallel To The Lathe Bed?To adjust the tailstock and make it parallel to the lathe bed, you can use a few tools. A wooden ruler can help you measure and check the distance. A dial indicator is great for more precise measurements. You might also need a wrench to tighten or loosen screws. Using these tools, you can make sure the tailstock is just right.

How Does Tailstock Misalignment Affect The Accuracy Of Machining Operations On A Metal Lathe?When the tailstock is misaligned on a metal lathe, it can cause problems. You might end up with wobbly pieces. This wobbling makes cuts uneven and can ruin your work. It also makes it harder to get the right shape. So, it’s important to make sure everything is lined up correctly for better results.

What Are The Step-By-Step Procedures For Aligning The Tailstock After It Has Been Adjusted Or Replaced?To align the tailstock, first make sure the machine is off. Next, check that the tailstock is tight against the bed. Then, use a dial indicator on the workpiece to see if it’s straight. Adjust the tailstock until the indicator reads zero. Finally, test the alignment by running a piece of work to see if it’s smooth.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Application Guide For Metal Lathe Tailstock Alignment:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! When using a metal lathe, the tailstock helps keep the workpiece steady. We need to make sure it’s lined up with the main part of the lathe. If it’s not straight, it can make parts uneven. To check alignment, you can use a special tool, called a dial indicator. Always take your time to get it right!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate A Misaligned Tailstock On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the tailstock on a metal lathe is misaligned, you might notice a few things. The parts you make could be uneven or out of shape. You may see a wobble when the machine is running. Sometimes, the tool won’t cut straight. Checking these signs helps us fix the problem quickly.”}},{“@type”: “Question”,”name”: “How Can You Accurately Measure Tailstock Alignment In A Metal Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check tailstock alignment on a metal lathe, you can use a tool called a dial indicator. First, place the dial indicator on the lathe bed and set it against the tailstock. Then, slide the tailstock along the lathe and watch the dial. If the needle stays still, the tailstock is aligned. If it moves, you may need to adjust the tailstock until it’s straight.”}},{“@type”: “Question”,”name”: “What Tools Are Recommended For Adjusting The Tailstock To Ensure It Is Parallel To The Lathe Bed?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To adjust the tailstock and make it parallel to the lathe bed, you can use a few tools. A wooden ruler can help you measure and check the distance. A dial indicator is great for more precise measurements. You might also need a wrench to tighten or loosen screws. Using these tools, you can make sure the tailstock is just right.”}},{“@type”: “Question”,”name”: “How Does Tailstock Misalignment Affect The Accuracy Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the tailstock is misaligned on a metal lathe, it can cause problems. You might end up with wobbly pieces. This wobbling makes cuts uneven and can ruin your work. It also makes it harder to get the right shape. So, it’s important to make sure everything is lined up correctly for better results.”}},{“@type”: “Question”,”name”: “What Are The Step-By-Step Procedures For Aligning The Tailstock After It Has Been Adjusted Or Replaced?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align the tailstock, first make sure the machine is off. Next, check that the tailstock is tight against the bed. Then, use a dial indicator on the workpiece to see if it’s straight. Adjust the tailstock until the indicator reads zero. Finally, test the alignment by running a piece of work to see if it’s smooth.”}}]}