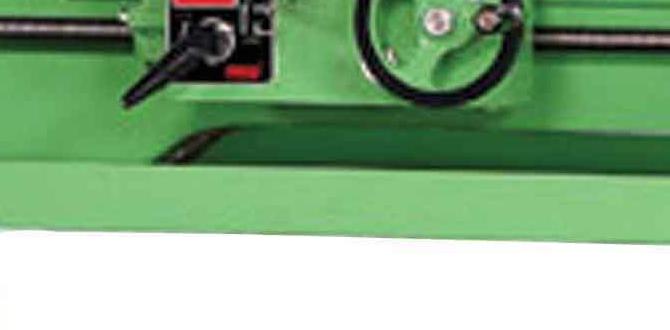

Have you ever wondered how metal parts are made? Metal lathes play a big role in this process. These machines help shape and cut metal into precise forms. Whether you’re a hobbyist or a professional, knowing about lathe applications is key.

Imagine building a model car. You need wheels, axles, and a body. A metal lathe helps you create these parts with accuracy. It’s not just for experts; anyone can learn to use lathe tools. Did you know that lathes have existed for thousands of years? They were once simple tools, but now they are powerful machines.

This guide to lathe applications will help you understand different metal lathe tools. You’ll discover how to use them safely and effectively. You might even find a new hobby or improve your skills. Are you ready to dive into the exciting world of metal lathes?

Comprehensive Lathe Application Guide: Metal Lathe Tools

Lathe Application Guide for Metal Lathe Tools

Discover how to use metal lathe tools effectively with this comprehensive lathe application guide. Learn about the different types of lathes and their specific functions. Whether you’re a beginner or an experienced user, understanding tool setup, safety practices, and maintenance is crucial. Did you know that a well-maintained lathe can last for decades? This guide helps you master essential techniques and achieve precise results in your projects, making your metalworking journey enjoyable and rewarding.Understanding Metal Lathes

Types of metal lathes and their functionalities. Key components of metal lathes and their roles.Metal lathes are amazing machines that shape metal into useful parts. There are several types of metal lathes, each with its unique job. For example, CNC lathes use computers for precise work. Engine lathes are versatile and can handle various tasks. Key parts of metal lathes include:

- Bed: The main support for all components.

- Spindle: Holds and rotates the workpiece.

- Tool Rest: Supports cutting tools.

- Tailstock: Helps position and stabilize the workpiece.

Each part plays a crucial role in making sure the lathe works well.

What are the types of metal lathes?

There are three main types of metal lathes: CNC lathes for computer control, engine lathes for general tasks, and automatic lathes for mass production.

Setting Up Your Metal Lathe

Stepbystep guide to properly install and calibrate a lathe. Safety precautions to consider during setup.Setting up a metal lathe is an important task. Follow these steps to do it right:

- Place the lathe on a sturdy surface.

- Check and tighten all bolts and screws.

- Level the lathe using a bubble level.

- Connect it to the power source.

- Calibrate the speed and feed settings.

Safety is key during setup. Here are some precautions:

- Wear safety goggles and gloves.

- Keep hair and loose clothing away from moving parts.

- Make sure the area is clean and organized.

Basic Turning Operations

Explanation of turning and its importance in metalworking. Techniques for achieving precision in basic turning tasks.Turning is like the dance of metal! It’s when a lathe spins a piece of material to shape it into something useful. This process is vital in metalworking because it helps create precise parts for machines. To achieve that precision, keep the tool sharp, adjust the speed according to the material, and use steady hands. Remember, even a little wobble can lead to a bumpy ride! Here’s a quick guide:

| Technique | Description |

|---|---|

| Sharp Tools | Keep your tools sharp for cleaner cuts! |

| Speed Control | Adjust speeds based on what you’re working with. |

| Steady Hands | Keep your hands steady; no one likes a shaky dance! |

Maintenance of Metal Lathe Tools

Routine maintenance practices to prolong tool life. Troubleshooting common issues with metal lathe tools.To keep metal lathe tools in top shape, routine maintenance is key. Regularly clean the tools to remove dust and debris. Check for any wear and tear; catching issues early can save time and money. Here are some essential practices:

- Lubricate moving parts to reduce friction.

- Inspect belts and replace if worn.

- Tighten loose screws and bolts.

- Sharpen cutting tools for better performance.

If a tool stops working properly, troubleshoot these common problems:

- Is it making strange noises?

- Is it cutting unevenly?

- Does it overheat?

By following these tips, you can prolong the life of your tools!

What are some common issues with metal lathe tools?

Common issues include strange noises, uneven cutting, and overheating. Troubleshooting these can help ensure your lathe runs smoothly.

Applications of Metal Lathing in Various Industries

Key industrial sectors that utilize metal lathe tools. Examples of products created through metal lathing processes.Metal lathing is a superstar in many industries! From automobile production to aerospace engineering, this tool works wonders. Think about how cars have shiny parts that fit perfectly—thank metal lathes for that! Lathes also help create items like machine parts, pipes, and even fun toys. Yes, your next toy might have been spun on a metal lathe! Here’s a little table to show where these amazing tools shine:

| Industry | Products |

|---|---|

| Automotive | Engine components, wheels |

| Aerospace | Precision parts, fittings |

| Manufacturing | Screws, bolts |

| Furniture | Stylish legs, knobs |

So, next time you see a perfectly round part, remember—it probably had a little help from a metal lathe!

Choosing the Right Metal Lathe for Your Needs

Factors to consider when selecting a metal lathe. Comparison of entrylevel vs. professionalgrade lathes.Picking the perfect metal lathe can feel like choosing between puppies at a shelter. There are a few important things to consider. First, think about the size of your projects. Smaller lathes are great for light work, while larger ones handle heavier materials. Then, you have entry-level vs. professional-grade lathes. Entry-level lathes are like puppy training wheels; they’re easier to use, but professional lathes pack a punch with more features.

| Type | Pros | Cons |

|---|---|---|

| Entry-Level | Affordable and user-friendly | Limited capability |

| Professional-Grade | High precision and versatile | Higher cost and steeper learning curve |

Remember, picking the right lathe can make your projects shine, just like finding the right pair of socks makes your shoes happy!

Resources for Further Learning

Recommended books and manuals on metal lathing techniques. Online courses and communities for metal lathe enthusiasts.Want to dive deeper into metal lathing? Check out some great books like The Art of Metal Lathing and Lathe Operations. They’re like treasure maps for beginners! Also, look for online courses that turn you into a lathe ninja. Websites like Skillshare and YouTube have tons of videos and tips. Don’t forget, joining communities can help, too! You’ll meet fellow metal lathe lovers who share tips. Here’s a quick look:

| Resource Type | Name |

|---|---|

| Books | The Art of Metal Lathing |

| Books | Lathe Operations |

| Online Course | Skillshare Metalworking Basics |

| Online Course | YouTube Metal Lathe Workshop |

| Community | Lathe Lovers Forum |

Conclusion

In conclusion, a lathe application guide helps you understand how to use metal lathe tools effectively. You learn about different tools, techniques, and safety tips. Remember to practice regularly to improve your skills. If you want to learn more, check out online tutorials or ask an expert. With these resources, you can become a pro at using your lathe!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Application Guide For Metal Lathe Tools:Sure! A lathe is a tool that shapes metal by spinning it and using sharp tools. You can cut, carve, or drill holes in metal pieces with it. To work safely, always wear goggles and follow the machine’s safety rules. With practice, you can make cool things like parts for machines or toys. Remember to keep your tools clean and sharp for the best results!

Sure! Please let me know the question you’d like me to answer.

What Are The Key Differences Between Carbide And High-Speed Steel (Hss) Cutting Tools For Metal Lathes?Carbide tools are made from a hard material that stays sharp longer than high-speed steel (HSS) tools. When you use carbide, it can cut metal faster without getting hot. HSS tools are good too, but they need more sharpening and wear out faster. You might pick carbide for tough jobs, while HSS is fine for lighter work. Both have a special purpose in metal lathes.

How Do You Determine The Appropriate Spindle Speed And Feed Rate For Different Metals While Using A Lathe?To find the right spindle speed and feed rate for different metals, we start by looking at the type of metal. Soft metals like aluminum need a faster speed, while hard metals like steel need a slower speed. You can use a chart that shows these speeds and rates for each metal type. Always remember to test a small piece first to make sure everything works well. Don’t forget to adjust if something doesn’t feel right!

What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Injuries?When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and remove loose clothing to avoid getting caught. Keep your hands away from moving parts while the machine is running. Make sure tools are in good shape and the area is clean to avoid tripping. Always follow the machine’s instructions carefully to stay safe.

How Can You Effectively Set Up A Lathe For Turning Complex Shapes And Contours In Metalwork?To set up a lathe for turning complex shapes, first, make sure the machine is clean and ready. Next, choose the right tool and hold it firmly in place. We then need to measure and mark where we want to cut on the metal. After that, we can slowly turn the lathe on and guide the metal into the tool. Always watch what you’re doing and keep fingers away from moving parts for safety.

What Are Some Common Troubleshooting Techniques For Addressing Issues Like Chatter And Tool Wear During Lathe Operations?To fix chatter and tool wear on a lathe, you can try a few things. First, check the speed of the lathe; sometimes, going slower helps reduce chatter. Next, make sure your tools are sharp. Dull tools can cause more wear. Finally, see if the piece you are working on is secure; loose parts can cause vibrations.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Application Guide For Metal Lathe Tools:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that shapes metal by spinning it and using sharp tools. You can cut, carve, or drill holes in metal pieces with it. To work safely, always wear goggles and follow the machine’s safety rules. With practice, you can make cool things like parts for machines or toys. Remember to keep your tools clean and sharp for the best results!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please let me know the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Key Differences Between Carbide And High-Speed Steel (Hss) Cutting Tools For Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Carbide tools are made from a hard material that stays sharp longer than high-speed steel (HSS) tools. When you use carbide, it can cut metal faster without getting hot. HSS tools are good too, but they need more sharpening and wear out faster. You might pick carbide for tough jobs, while HSS is fine for lighter work. Both have a special purpose in metal lathes.”}},{“@type”: “Question”,”name”: “How Do You Determine The Appropriate Spindle Speed And Feed Rate For Different Metals While Using A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To find the right spindle speed and feed rate for different metals, we start by looking at the type of metal. Soft metals like aluminum need a faster speed, while hard metals like steel need a slower speed. You can use a chart that shows these speeds and rates for each metal type. Always remember to test a small piece first to make sure everything works well. Don’t forget to adjust if something doesn’t feel right!”}},{“@type”: “Question”,”name”: “What Safety Precautions Should Be Taken When Operating A Metal Lathe To Prevent Accidents And Injuries?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a metal lathe, always wear safety goggles to protect your eyes. Tie back long hair and remove loose clothing to avoid getting caught. Keep your hands away from moving parts while the machine is running. Make sure tools are in good shape and the area is clean to avoid tripping. Always follow the machine’s instructions carefully to stay safe.”}},{“@type”: “Question”,”name”: “How Can You Effectively Set Up A Lathe For Turning Complex Shapes And Contours In Metalwork?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a lathe for turning complex shapes, first, make sure the machine is clean and ready. Next, choose the right tool and hold it firmly in place. We then need to measure and mark where we want to cut on the metal. After that, we can slowly turn the lathe on and guide the metal into the tool. Always watch what you’re doing and keep fingers away from moving parts for safety.”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Techniques For Addressing Issues Like Chatter And Tool Wear During Lathe Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix chatter and tool wear on a lathe, you can try a few things. First, check the speed of the lathe; sometimes, going slower helps reduce chatter. Next, make sure your tools are sharp. Dull tools can cause more wear. Finally, see if the piece you are working on is secure; loose parts can cause vibrations.”}}]}