Have you ever wondered how machines work smoothly? One secret lies in a simple task: oiling. In this article, we dive into the lathe apron oiling procedure. This is a job that keeps the lathe running well.

Imagine a busy workshop where the lathe spins and makes precise cuts. Now, picture the lathe struggling because it lacks proper oil. That’s where oiling comes in! Keeping the lathe’s apron oiled helps it move freely and last longer.

Did you know that regular maintenance can save you money and time? Just a little oil goes a long way in preventing wear and tear on your machine. So, are you ready to learn how to keep your lathe happy? Let’s explore the steps together!

Comprehensive Guide To Lathe Apron Oiling Procedure

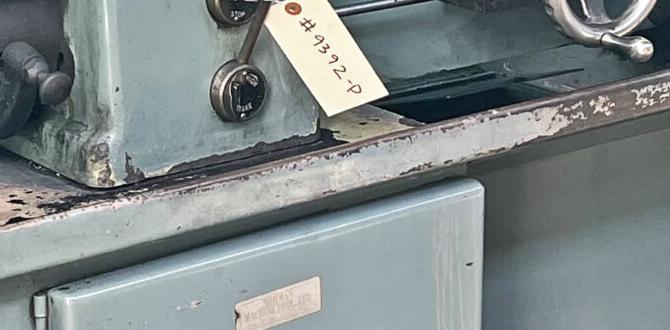

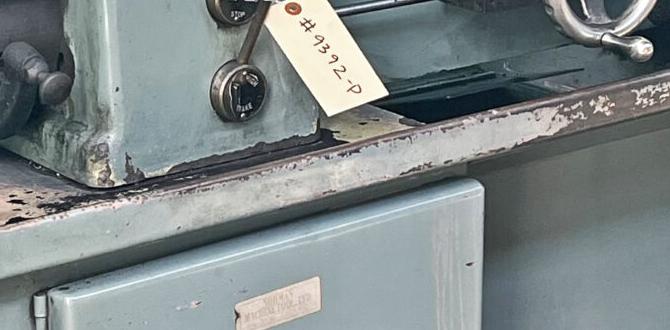

Lathe Apron Oiling Procedure

Caring for your lathe is crucial for its performance. Proper apron oiling keeps everything running smoothly. First, clean the apron to remove dirt and debris. Next, apply the recommended oil to the lubrication points. This helps prevent wear and tear. Did you know that regular oiling can increase the life of your lathe? Consistency is key! Following these simple steps will ensure your lathe remains in great shape for years to come.Importance of Lubrication in Lathe Maintenance

Explains the role of lubrication in ensuring lathe longevity and performance.. Discusses the consequences of neglecting oiling procedures..Keeping a lathe well-oiled is essential for its life and performance. Lubrication reduces friction, which means less wear and tear. Imagine your lathe skipping around like a kid on a sugar rush if it’s not oiled! Neglecting oiling can result in metal grinding against metal—yikes! This can lead to damage and costly repairs. Here’s a quick look at why oiling is important:

| Benefits of Lubrication | Consequences of Neglect |

|---|---|

| Increased Longevity | Premature Wear |

| Better Performance | Reduced Accuracy |

| Smooth Operation | Increased Noise |

Oiling your lathe is like giving it a cozy blanket—everyone feels better afterward!

Types of Oils Suitable for Lathe Aprons

Describes various oil types and their properties for lathe apron usage.. Recommendations for choosing the right oil based on machine requirements..Choosing the right oil for your lathe apron can feel like picking the best ice cream flavor at a shop. Each oil type has its own special qualities! Mineral oil is popular. It keeps everything running smooth like butter on hot toast. Synthetic oil lasts longer and resists heat, making it a great choice if your machine works hard. Vegetable oil is eco-friendly but might not be strong enough for heavy tasks. Check your machine’s needs to pick the best oil!

| Oil Type | Properties |

|---|---|

| Mineral Oil | Good lubricant, affordable, suitable for general use. |

| Synthetic Oil | Long-lasting, heat resistant, great for heavy-duty machines. |

| Vegetable Oil | Eco-friendly, not ideal for heavy use. |

Step-by-Step Oiling Procedure

Outlines the specific steps to properly oil a lathe apron.. Includes safety precautions to take before starting the oiling process..Follow these simple steps to oil your lathe apron safely and effectively. First, gather your tools: oil, a clean cloth, and a small container. Next, inspect your lathe. Make sure to turn it off and unplug it for safety. Then, gently clean the apron with the cloth. Be careful not to damage any parts. After that, apply the oil evenly. Wipe away any excess. This keeps your lathe running smoothly.

- Wear safety goggles.

- Make sure the work area is clean.

- Check all parts before starting.

Why is oiling the lathe apron important?

Oiling keeps the lathe functioning well and prevents wear. Regular maintenance ensures better performance and longer life for your machine.

Common Mistakes to Avoid During Oiling

Lists frequent errors made during the oiling procedure and their impacts.. Tips on how to ensure a proper and effective oiling process..Oiling your lathe apron can be tricky! Many folks miss spots or apply too much oil. This can cause clogs or make things slippery. Using the wrong type of oil is another blunder. It’s like putting soda in your car engine—yikes! Always check the oil type first. To avoid these goofs, remember to follow the right steps and keep your oiling area clean.

| Common Mistakes | Effects |

|---|---|

| Over or under-oiling | Can lead to clogs or rust |

| Wrong oil type | Can damage your lathe |

| Poor cleaning | Can cause dirt buildup |

Always clean your apron first and use a funnel to avoid mess. Treat your lathe like a king, and it will treat you well in return! Remember, a well-oiled machine is a happy machine.

Frequency of Oiling and Maintenance Schedule

Provides guidance on how often to oil the lathe apron based on usage.. Suggests a maintenance schedule to optimize machine performance..To keep your lathe running smoothly, oiling is important. Always check the apron after every use. If you use the lathe heavily, oil it every few hours. For lighter tasks, once a day is enough. Adopting a clear maintenance schedule helps your machine last longer and work better. Here’s a simple guide:

- **Light Use:** Oil daily.

- **Moderate Use:** Oil every few hours.

- **Heavy Use:** Check and oil after each use.

This keeps your lathe in top shape!

How Often Should You Oil a Lathe Apron?

Oiling the lathe apron is crucial to its performance. Regular oiling prevents wear and tear.

Signs That Your Lathe Apron Needs Oiling

Identifies indicators of inadequate lubrication and their implications.. Describes how to recognize the need for immediate maintenance..Recognizing when your lathe apron needs oiling is key. Look for these signs:

- Unusual noises while operating.

- Poor movement or sticking parts.

- Visible rust or wear.

If you see or hear these issues, act fast. Delaying maintenance might cause bigger problems. Keeping everything well-oiled preserves your machine’s life and performance.

How can I tell if my lathe apron needs oiling?

Check for loud sounds, sluggish movement, or rust. These signs show that your lathe apron is not getting enough oil.

Comparative Analysis of Manual vs. Automatic Oiling Systems

Compares the effectiveness and efficiency of manual versus automatic oiling systems.. Discusses the pros and cons of each system for lathe users..Choosing between manual and automatic oiling systems is important for lathe users. Both have their benefits and drawbacks.

Manual Oiling System:

- Effective control over oiling points

- Requires regular attention from the user

- Lower maintenance costs

Automatic Oiling System:

- Less user effort needed

- Provides consistent oil flow

- Higher upfront cost

In summary, manual systems give more control, while automatic systems save time. Choosing the right one depends on your needs!

Why choose a manual system?

Manual systems allow for direct control, letting users ensure proper oil levels at all times.

What are the benefits of automatic systems?

Automatic systems offer convenience and consistent lubrication, ideal for busy workshops.

Frequently Asked Questions about Lathe Apron Oiling

Compiles common inquiries related to lathe apron oiling.. Provides concise answers and additional resources for further reading..Many people have questions about lathe apron oiling. Here are some common inquiries and their answers:

How often should I oil the lathe apron?

It’s best to oil the lathe apron every week or after every major use.

What type of oil is recommended?

Use a light machine oil or a specific lathe oil for best results.

Can I over-oil the apron?

Yes, too much oil can attract dust and dirt, causing wear.

Where can I find more information?

- Check the manufacturer’s manual.

- Visit trusted online forums and websites.

- Ask an expert or a local technician.

These tips help ensure your lathe stays in good shape. Keep learning for better maintenance!

Conclusion

In summary, the lathe apron oiling procedure is essential for smooth operation. Regular oiling keeps your machine running well and extends its life. Always check oil levels and apply the right oil carefully. We encourage you to practice these steps regularly. For more details, consider reading your lathe’s manual. This helps you gain confidence in your skills!FAQs

Sure! Here Are Five Questions Related To The Lathe Apron Oiling Procedure:1. What is a lathe apron? A lathe apron is a part of a machine called a lathe. It helps control how the tool moves. 2. Why do we oil the lathe apron? We oil the lathe apron to keep it moving smoothly. Oil helps reduce friction and wear. 3. How often should you oil the apron? You should oil the apron every time you use the lathe. This keeps everything working well. 4. What kind of oil should you use? You should use machine oil or lubricant made for machines. This oil works best for moving parts. 5. How do you apply the oil? You can use a small oil can to put oil on the apron. Be careful not to use too much!

Sure! Please give me the question you want me to answer.

What Types Of Oil Are Recommended For Lubricating The Apron Of A Lathe, And Why Is Proper Oil Selection Important?You should use a light machine oil or way oil for the apron of a lathe. These oils help the machine move smoothly and last longer. Using the right oil keeps parts from wearing out and helps everything work better. It’s important to choose the right oil to avoid problems and keep the lathe safe.

How Often Should The Apron Of A Lathe Be Oiled, And What Factors Might Influence The Frequency Of Maintenance?You should oil the apron of a lathe regularly, about once a month. This keeps it working well. Factors that can change this are how often you use the lathe and the environment. If you use it a lot or it’s really dusty, you might need to oil it more often. Always check to see if it needs oil!

What Steps Should Be Followed To Properly Oil The Lathe Apron, Including Any Specific Points That Need Special Attention?To oil the lathe apron, first, turn off the machine. Then, clean any dust or dirt. Next, find the oil ports on the apron and add a few drops of oil. Special attention should go to moving parts to keep them working smoothly. Finally, check for any spills and wipe them up to keep everything neat.

What Are The Common Signs That Indicate The Lathe Apron May Require Oiling Or Maintenance?You can tell the lathe apron needs oiling if it makes strange noises while working. If it moves slowly or feels stiff, that’s a sign too. You might notice some parts wearing down or looking rusty. If you see any leaks, it definitely needs attention. Always keep it well-oiled to keep it running smoothly!

How Does Inadequate Lubrication Of The Lathe Apron Affect The Overall Performance And Longevity Of The Lathe?If you don’t add enough oil to the lathe apron, it can cause problems. The apron helps move the tools smoothly. Without proper lubrication, parts can get stuck and wear out faster. This means your lathe won’t work as well and won’t last as long. Regular oiling keeps everything running smoothly and helps the lathe stay in good shape.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Lathe Apron Oiling Procedure:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “1. What is a lathe apron? A lathe apron is a part of a machine called a lathe. It helps control how the tool moves. 2. Why do we oil the lathe apron? We oil the lathe apron to keep it moving smoothly. Oil helps reduce friction and wear. 3. How often should you oil the apron? You should oil the apron every time you use the lathe. This keeps everything working well. 4. What kind of oil should you use? You should use machine oil or lubricant made for machines. This oil works best for moving parts. 5. How do you apply the oil? You can use a small oil can to put oil on the apron. Be careful not to use too much!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please give me the question you want me to answer.”}},{“@type”: “Question”,”name”: “What Types Of Oil Are Recommended For Lubricating The Apron Of A Lathe, And Why Is Proper Oil Selection Important?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should use a light machine oil or way oil for the apron of a lathe. These oils help the machine move smoothly and last longer. Using the right oil keeps parts from wearing out and helps everything work better. It’s important to choose the right oil to avoid problems and keep the lathe safe.”}},{“@type”: “Question”,”name”: “How Often Should The Apron Of A Lathe Be Oiled, And What Factors Might Influence The Frequency Of Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You should oil the apron of a lathe regularly, about once a month. This keeps it working well. Factors that can change this are how often you use the lathe and the environment. If you use it a lot or it’s really dusty, you might need to oil it more often. Always check to see if it needs oil!”}},{“@type”: “Question”,”name”: “What Steps Should Be Followed To Properly Oil The Lathe Apron, Including Any Specific Points That Need Special Attention?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To oil the lathe apron, first, turn off the machine. Then, clean any dust or dirt. Next, find the oil ports on the apron and add a few drops of oil. Special attention should go to moving parts to keep them working smoothly. Finally, check for any spills and wipe them up to keep everything neat.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate The Lathe Apron May Require Oiling Or Maintenance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell the lathe apron needs oiling if it makes strange noises while working. If it moves slowly or feels stiff, that’s a sign too. You might notice some parts wearing down or looking rusty. If you see any leaks, it definitely needs attention. Always keep it well-oiled to keep it running smoothly!”}},{“@type”: “Question”,”name”: “How Does Inadequate Lubrication Of The Lathe Apron Affect The Overall Performance And Longevity Of The Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If you don’t add enough oil to the lathe apron, it can cause problems. The apron helps move the tools smoothly. Without proper lubrication, parts can get stuck and wear out faster. This means your lathe won’t work as well and won’t last as long. Regular oiling keeps everything running smoothly and helps the lathe stay in good shape.”}}]}