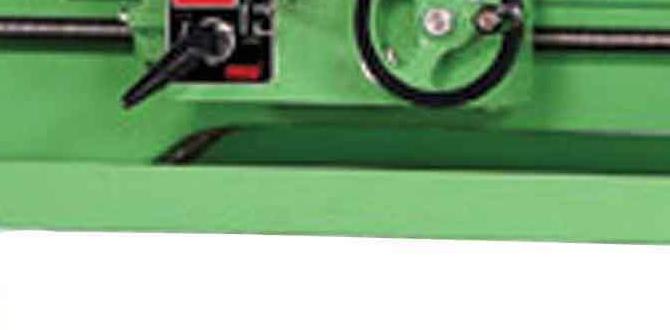

Have you ever wondered how metal parts are made with such precision? It’s not just magic—it’s the work of machines like lathes. These machines can shape metal into many useful items. One important part of a lathe is its handwheel. This handy tool helps operators control the lathe easily.

Today, we will explore something exciting: lathe CAD files. These files help you design and create handwheels for metal lathes. Imagine being able to customize a handwheel to fit your unique project needs! This opens up a whole new world for hobbyists and professionals alike.

Did you know that with the right CAD files, you can even print your own handwheel? It’s like making your own tools at home! As we dive deeper, we’ll learn how to find these files and use them to improve your metal lathe skills.

Lathe Cad Files: Metal Lathe Handwheel Design Guide

Understanding Lathe CAD Files for Metal Lathes

Are you curious about how metal lathes work? Lathe CAD files play a critical role in creating precise designs for parts. These digital blueprints guide the handwheel, ensuring everything runs smoothly. Have you ever wondered how such detailed plans are made? With the right CAD files, even beginners can craft intricate designs with ease. It’s exciting to see how technology amplifies our ability to create and innovate in metalworking!Understanding the Basics of Lathe CAD Files

Definition of CAD files in the context of metal lathes. Importance of CAD files for design and manufacturing processes.CAD files are digital blueprints for metal lathes. They show how parts fit together. These files are crucial for designing and making tools. They help workers visualize what they need. With CAD files, mistakes are fewer, saving time and money. They ensure accuracy, which is vital in manufacturing.

What are the key benefits of using CAD files?

- Accuracy: CAD files reduce errors in designs.

- Efficiency: They speed up the design process.

- Visualization: CAD allows users to see the final product before making it.

How to Create Effective CAD Files for Metal Lathe Handwheels

Stepbystep process for designing handwheels in CAD. Best practices for ensuring compatibility with metal lathes.Creating CAD files for metal lathe handwheels can be easy and fun! Start with a clear plan. Sketch your design on paper first. Next, use your favorite CAD software to shape it up. Ensure all dimensions match your lathe for a snug fit. Check materials too! Metal lathes love durable designs. Keep the design simple to avoid tricky surprises. Remember, even handwheels need a little twist of humor, right?

| Steps | Tips |

|---|---|

| 1. Sketch Design | Keep it simple! |

| 2. Use CAD Software | Check your tools! |

| 3. Match Dimensions | Exact is key! |

| 4. Select Material | Metal is best! |

Follow these steps and enjoy crafting your perfect handwheel!

Common Issues in Lathe CAD Design and How to Solve Them

Identification of frequent design pitfalls. Tips for troubleshooting CAD file errors.Designing CAD files for lathes can be tricky. Many users face issues that slow them down. Common problems include:

- Poor dimensions.

- Missing parts.

- Incompatible file types.

To troubleshoot, here are helpful tips:

- Double-check all measurements.

- Use the correct file format.

- Look for hidden errors before finalizing.

Staying organized can save time and enhance your design.

What are frequent CAD file mistakes in lathe design?

Frequent errors include incorrect dimensions, missing components, and using wrong file formats.

How can I fix CAD file errors in metal lathe designs?

- Verify all dimensions carefully.

- Ensure you are exporting in a supported file type.

- Review design thoroughly for parts or features that may be overlooked.

Optimizing CAD Files for Performance and Accuracy

Techniques for optimizing CAD files for precision engineering. Importance of file formats and settings for performance.Optimizing CAD files is key to making precise metal parts. Start by using the right file formats, like STL or STEP, which are great for performance. Check your settings, as little tweaks can make a big difference—think of it like adjusting the seasoning in your favorite recipe! To help you, here’s a quick look at some important aspects:

| Aspect | Best Practice |

|---|---|

| File Format | Use STL or STEP |

| Layer Management | Keep it organized! |

| File Size | Avoid bloat, trim the fat! |

These tips can help you create awesome metal parts with your lathe. Remember, a happy engineer is a productive engineer!

Sharing and Collaborating on Lathe CAD Files

Best practices for sharing CAD files with teams and stakeholders. Tools and platforms for effective collaboration.Effective sharing of CAD files can boost teamwork. Always use clear file names. This helps everyone find the right files fast. Use cloud storage like Google Drive or Dropbox for easy access. It’s also good to choose the right format, like STL or DXF. This way, everyone can open the files. Regularly check for updates and communicate changes with your team. Set clear deadlines to keep projects on track.

What tools can help with sharing and collaborating on CAD files?

Popular tools include:

- Google Drive

- Dropbox

- Microsoft Teams

- Autodesk BIM 360

- GrabCAD Workbench

Using these tools, teams can work together easily. They allow multiple people to discuss and edit designs at the same time. This teamwork leads to better results. Remember, sharing is key for a successful project!

Case Studies: Successful Metal Lathe Handwheel Designs

Examples of innovative handwheel designs and their CAD file sources. Lessons learned from successful design projects.Several metal lathe handwheel designs show innovation and creativity. Each design teaches us valuable lessons. For instance, a well-rounded handwheel offers better grip and control. Here are some top examples that highlight successful designs and their CAD file sources:

- Ergonomic shape for comfortable use.

- Lightweight materials for easy turning.

- Color-coded sections for better visibility.

These designs improve functionality and showcase how creative thinking leads to better tools.

What are CAD file sources for handwheel designs?

Many places offer CAD files. Some popular sources include GrabCAD, Thingiverse, and Cults3D. These sites have many examples for you to explore and use.

The Future of CAD in Metalworking and Lathe Technology

Emerging trends in CAD technology within the metalworking industry. Potential impacts of advanced CAD developments on lathe design and manufacturing.New CAD technology is changing metalworking. It makes machines like lathes easier and faster to design. Here are some exciting trends:

- 3D modeling: Allows for quick changes and better design.

- Automation: Saves time in the manufacturing process.

- Collaboration: Teams can work together online.

These changes will help create stronger and more precise designs for products, like the lathe CAD files metal lathe handwheel. Overall, the future looks bright for metalworking with CAD.

What is the impact of CAD on lathe design?

CAD improves lathe design by making it faster and more accurate. Designers can easily change parts and test ideas.Conclusion

In summary, lathe CAD files for metal lathe handwheels help you create precise designs. These files save time and improve accuracy. Using them can bring your projects to life. We encourage you to explore more about CAD design and practice using these files. With hands-on experience, you’ll become more confident in your metalworking skills!FAQs

Certainly! Here Are Five Related Questions On The Topic Of Lathe Cad Files For A Metal Lathe Handwheel:You can find CAD files for metal lathe handwheels on websites like Thingiverse or GrabCAD. These files are special designs you can use with a 3D printer. To use them, first download the file to your computer. Then, you can print it to make a real handwheel. It’s a fun way to create your own parts!

Sure! Please provide the question you would like me to answer.

What Design Features Should Be Considered When Creating Cad Files For A Metal Lathe Handwheel?When creating CAD files for a metal lathe handwheel, you should think about size and shape. The handwheel needs to fit comfortably in your hand. You also want to make sure it has proper holes for screws. Lastly, think about making it strong enough to last and easy to hold onto. These features help the handwheel work better!

Are There Any Recommended Cad Software Tools Specifically Suited For Designing Lathe Handwheels?Yes, there are good CAD (Computer-Aided Design) software tools for designing lathe handwheels. You might like Tinkercad because it’s simple and free. SolidWorks is another option, but it can be more complex. SketchUp is user-friendly too. Choose one that feels right for you!

How Can I Ensure That My Cad Files For A Handwheel Are Compatible With Different Metal Lathe Models?To make sure your CAD files for a handwheel work with different metal lathes, use common file types like .DXF or .STL. Check the sizes and shapes of other handwheels first. You can ask people who own different lathes about their needs. Lastly, always test your files with the lathes before using them. This way, you can be sure they fit!

What Materials Are Commonly Used In Fabricating Lathe Handwheels, And How Can This Affect The Cad Design?Lathe handwheels are often made from metal, plastic, or sometimes wood. Metal is strong and lasts a long time, while plastic is lighter and can be colorful. When we design in CAD (Computer-Aided Design), we need to think about these materials. If we use metal, we might need thicker parts. If we use plastic, we can make the shapes more fun and creative.

How Can I Optimize The Cad File For Printing A Metal Lathe Handwheel Prototype?To optimize your CAD file for printing a metal lathe handwheel prototype, first, check the size and shape. Make sure it fits the printer’s limits. Next, remove any extra details that won’t show up well. You can also use simple shapes to make it stronger. Finally, save it in the right file format for 3D printing, like STL.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Certainly! Here Are Five Related Questions On The Topic Of Lathe Cad Files For A Metal Lathe Handwheel:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can find CAD files for metal lathe handwheels on websites like Thingiverse or GrabCAD. These files are special designs you can use with a 3D printer. To use them, first download the file to your computer. Then, you can print it to make a real handwheel. It’s a fun way to create your own parts!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Design Features Should Be Considered When Creating Cad Files For A Metal Lathe Handwheel?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When creating CAD files for a metal lathe handwheel, you should think about size and shape. The handwheel needs to fit comfortably in your hand. You also want to make sure it has proper holes for screws. Lastly, think about making it strong enough to last and easy to hold onto. These features help the handwheel work better!”}},{“@type”: “Question”,”name”: “Are There Any Recommended Cad Software Tools Specifically Suited For Designing Lathe Handwheels?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are good CAD (Computer-Aided Design) software tools for designing lathe handwheels. You might like Tinkercad because it’s simple and free. SolidWorks is another option, but it can be more complex. SketchUp is user-friendly too. Choose one that feels right for you!”}},{“@type”: “Question”,”name”: “How Can I Ensure That My Cad Files For A Handwheel Are Compatible With Different Metal Lathe Models?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure your CAD files for a handwheel work with different metal lathes, use common file types like .DXF or .STL. Check the sizes and shapes of other handwheels first. You can ask people who own different lathes about their needs. Lastly, always test your files with the lathes before using them. This way, you can be sure they fit!”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used In Fabricating Lathe Handwheels, And How Can This Affect The Cad Design?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe handwheels are often made from metal, plastic, or sometimes wood. Metal is strong and lasts a long time, while plastic is lighter and can be colorful. When we design in CAD (Computer-Aided Design), we need to think about these materials. If we use metal, we might need thicker parts. If we use plastic, we can make the shapes more fun and creative.”}},{“@type”: “Question”,”name”: “How Can I Optimize The Cad File For Printing A Metal Lathe Handwheel Prototype?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To optimize your CAD file for printing a metal lathe handwheel prototype, first, check the size and shape. Make sure it fits the printer’s limits. Next, remove any extra details that won’t show up well. You can also use simple shapes to make it stronger. Finally, save it in the right file format for 3D printing, like STL.”}}]}