Have you ever watched a metal lathe at work? It’s fascinating! A metal lathe can shape metal into amazing designs. But how do makers create those perfect parts?

That’s where lathe CAD files come in! These digital files help designers plan and create exact shapes for their projects. One of the essential parts of a metal lathe is the saddle. This piece holds the work securely while the machine spins.

Imagine building your first metal project. You feel excited and a bit nervous. But with the right lathe CAD files, you can bring your ideas to life! Did you know that many hobbyists and engineers share their designs online? This sharing makes it easier for everyone to start creating.

In this article, we will explore how lathe CAD files for metal lathe saddles can help you become a better maker. Let’s dive into the world of metalworking and see what you can create!

Lathe Cad Files: Essential Metal Lathe Saddle Designs

Lathe CAD Files: Understanding Metal Lathe Saddles

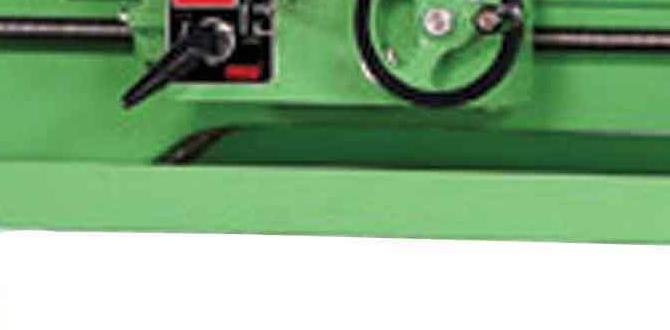

Lathe CAD files are essential tools for anyone working with metal lathes. They help in designing precise parts, especially the lathe saddle. The saddle holds the cutting head and allows smooth movement. Have you ever wondered how manufacturers create such detailed components? The magic lies in these CAD files. They provide exact measurements and shape outlines, making it easier to produce high-quality parts. Discovering how these files work opens a world of creativity and precision in metalworking!Understanding Lathe CAD Files

Definition and purpose of CAD files in lathe manufacturing.. Common formats and software used for lathe CAD files..CAD files are like magic blueprints for lathes. They show exactly how parts should be shaped and cut. This helps manufacturers create items accurately and quickly. Common software to make these files include AutoCAD and SolidWorks. They produce formats such as DWG and DXF. Each format keeps information neat and tidy, like a well-organized sock drawer! Here’s a quick peek at some popular formats:

| Format | Description |

|---|---|

| DWG | Used for 2D and 3D design drawings. |

| DXF | Great for sharing designs between different software. |

| STL | Popular for 3D printing and models. |

Using the right CAD file helps avoid mistakes, and let’s be honest, nobody likes a crooked part! So, choose your format wisely.

Importance of Lathe Saddles in Metalworking

Role of saddles in the functionality of a lathe.. Impact of saddle design on precision and efficiency..Lathe saddles play a crucial part in metalworking. They hold the workpiece securely while spinning, like a trusty friend who won’t let you fall off a bike! A well-designed saddle ensures smooth movements, enhancing precision and efficiency. If the saddle is wobbly, your cuts can be wonkier than a three-legged race! Just remember, better saddle design can lead to better results, making your projects shine like a freshly polished trophy. So, choosing the right lathe saddle matters!

| Feature | Impact |

|---|---|

| Precision | Improved accuracy in cuts |

| Stability | Reduces vibrations during operation |

| Design | Enhances overall efficiency |

Creating Effective Lathe CAD Files

Stepbystep guide to developing CAD files for lathe saddles.. Tips for ensuring accuracy and compatibility with lathe machines..Creating CAD files for lathe saddles can feel like building a Lego castle. Here’s a simple step-by-step guide to help you out. First, sketch your design on paper—imagination is key! Then, use CAD software to bring your drawing to life. Be sure to double-check your measurements to ensure everything fits like a glove. Lastly, save your files in a format compatible with most lathe machines, like .dxf or .dwg.

| Tip | Description |

|---|---|

| Accuracy | Always measure twice before locking in your designs. |

| Compatibility | Use widely accepted file formats to avoid tech headaches! |

Remember, creating CAD files can be fun! It’s like giving your lathe a new toy to play with. So, don’t stress too much—after all, even the best designers had to start somewhere!

Common Features of Metal Lathe Saddle Designs

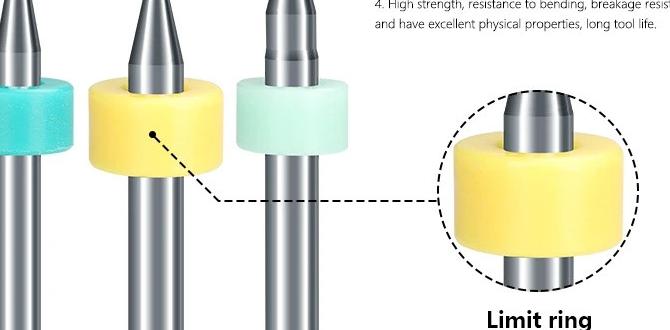

Key geometric and functional characteristics.. Innovative design elements that enhance performance..Metal lathe saddles come in various designs that help perform jobs better. They typically share key features like stability and precision, crucial for turning metal into smooth shapes. Many designs also include innovative features, like improved locking mechanisms that make them extra sturdy. It’s like giving your lathe a superhero cape! Below is a table that shows some common characteristics:

| Feature | Description |

|---|---|

| Stability | Ensures smooth operations without wobbles. |

| Precision | Helps in making accurate cuts every time. |

| Locking Mechanism | Keeps everything secure while you work. |

| Material Quality | Durable materials resist wear and tear. |

These features work together giving users a fantastic experience. So, next time your lathe seems extra smooth, thank its saddle for being so awesome!

Best Practices for Sharing and Using Lathe CAD Files

Platforms and resources for sharing CAD designs.. Guidelines for file versioning and updates..Sharing CAD files can feel like launching a rocket, but it doesn’t have to be complicated! Use platforms like GrabCAD or Thingiverse to make sharing easier. They allow you to upload and get feedback quickly. For updates, keep your files organized. Number them like a TV series—Season 1, Episode 2, and so on. This way, everyone knows which version is which.

| Platform | Benefits |

|---|---|

| GrabCAD | Great for collaboration and feedback. |

| Thingiverse | User-friendly and fun for sharing designs. |

Following these simple steps can turn a mountain of CAD files into a well-organized molehill. Who knew sharing files could be this fun?

Challenges in Designing Lathe Saddles

Common design pitfalls and troubleshooting tips.. Techniques for optimizing saddle designs for different types of lathes..Designing lathe saddles can be tricky. Many face common challenges. Poor design can lead to inaccurate cuts. Materials might not work well together. It is essential to check the fit and strength of parts. Some tips include:

- Choose the right material for your lathe.

- Ensure the saddle fits tight but moves smoothly.

- Test designs with small models first.

Optimizing saddle designs improves performance. Different lathes may need different designs. Knowing your lathe helps you create better saddles.

What are common pitfalls in lathe saddle design?

Common pitfalls include poor fit and material incompatibility. These problems can cause malfunction and affect the quality of work.

Resources for Further Learning and Inspiration

Recommended books, websites, and online courses.. Community forums and workshops for lathe enthusiasts..Learning about lathes can be fun and exciting! There are great resources to help you dive deeper into the world of metal working. Check out these recommendations:

- **Books:** Look for titles that cover metalworking basics and projects. They can be wonderful guides.

- **Websites:** Search for sites dedicated to lathes. They often have tips and tricks!

- **Online Courses:** These can help you learn step-by-step. Many are free or low-cost.

- **Community Forums:** Join discussions with other enthusiasts. Share ideas and ask questions.

- **Workshops:** Attend local workshops to practice hands-on skills. It’s a great way to meet others too!

These resources can inspire you to create amazing projects with your lathe. Having the right tools and knowledge makes all the difference!

What are some good online resources for lathe enthusiasts?

Recommended online resources include specialized websites and forums focused on metalworking. These platforms provide videos, articles, and even online communities to discuss tips and share experiences.

Conclusion

In summary, lathe CAD files for metal lathe saddles are useful tools for DIY projects. They help you design and create precise parts easily. You can find many free resources online. We encourage you to explore these files and start your own projects. Remember, practice makes perfect, so keep learning and building!FAQs

Sure! Here Are Five Related Questions On The Topic Of Cad Files For A Metal Lathe Saddle:Sure! Here are five questions about CAD files for a metal lathe saddle: 1. What is a CAD file? A CAD file is a drawing made on a computer. It shows how to create something, like a metal lathe saddle. 2. Why do we need CAD files? We need CAD files to design parts accurately. They help us see the shape and size before making things. 3. How do we use CAD files? We open them in special software. Then, we can see the design and make changes if needed. 4. Can anyone create CAD files? Yes! Anyone can learn to use CAD software. With practice, you can create your own designs. 5. What is a metal lathe saddle? The metal lathe saddle is a part that holds and moves the tool. It helps shape the metal into different forms.

Of course! Please provide the question you would like me to answer.

What Are The Essential Design Parameters To Consider When Creating Cad Files For A Metal Lathe Saddle?When making CAD files for a metal lathe saddle, focus on size and shape. You need to know how big it should be. Check the holes for screws and where parts fit together. Think about how strong it needs to be. Lastly, make sure it can be made from metal easily.

How Can Cad Software Be Effectively Utilized To Simulate The Performance Of A Metal Lathe Saddle Before Production?You can use CAD software to create a 3D model of the metal lathe saddle. This lets you see how it will look and work. You can test how it moves and fits with other parts. If you find problems, you can fix them in the software before making the real thing. This saves time and materials!

What Common Materials Are Recommended For Fabricating A Metal Lathe Saddle, And How Can These Be Represented In Cad Files?To make a metal lathe saddle, you can use materials like steel or aluminum. These materials are strong and durable. In CAD files, we can show these materials using colors and textures. This helps us see what the saddle will look like in real life.

Are There Specific Cad File Formats That Are Preferred For Sharing Designs Of Metal Lathe Saddles Among Engineers And Manufacturers?Yes, there are some popular file formats for sharing designs. We often use DXF (Drawing Exchange Format) and STL (Stereolithography) files. These formats work well when sharing designs because many people can open them. You can easily send these files to engineers and manufacturers to help them understand your design.

How Can Cad Files For Metal Lathe Saddles Be Optimized For Printing Or Cnc Machining Processes?To make CAD files for metal lathe saddles better for printing or CNC machining, we should keep the design simple. Use clear shapes and avoid small details that might be hard to print or cut. We can also check the sizes to make sure they fit well together. Lastly, we need to save the file in a format that the printer or machine can understand easily. This way, we get strong and accurate parts!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Cad Files For A Metal Lathe Saddle:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions about CAD files for a metal lathe saddle: 1. What is a CAD file? A CAD file is a drawing made on a computer. It shows how to create something, like a metal lathe saddle. 2. Why do we need CAD files? We need CAD files to design parts accurately. They help us see the shape and size before making things. 3. How do we use CAD files? We open them in special software. Then, we can see the design and make changes if needed. 4. Can anyone create CAD files? Yes! Anyone can learn to use CAD software. With practice, you can create your own designs. 5. What is a metal lathe saddle? The metal lathe saddle is a part that holds and moves the tool. It helps shape the metal into different forms.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Of course! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Essential Design Parameters To Consider When Creating Cad Files For A Metal Lathe Saddle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When making CAD files for a metal lathe saddle, focus on size and shape. You need to know how big it should be. Check the holes for screws and where parts fit together. Think about how strong it needs to be. Lastly, make sure it can be made from metal easily.”}},{“@type”: “Question”,”name”: “How Can Cad Software Be Effectively Utilized To Simulate The Performance Of A Metal Lathe Saddle Before Production?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use CAD software to create a 3D model of the metal lathe saddle. This lets you see how it will look and work. You can test how it moves and fits with other parts. If you find problems, you can fix them in the software before making the real thing. This saves time and materials!”}},{“@type”: “Question”,”name”: “What Common Materials Are Recommended For Fabricating A Metal Lathe Saddle, And How Can These Be Represented In Cad Files?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make a metal lathe saddle, you can use materials like steel or aluminum. These materials are strong and durable. In CAD files, we can show these materials using colors and textures. This helps us see what the saddle will look like in real life.”}},{“@type”: “Question”,”name”: “Are There Specific Cad File Formats That Are Preferred For Sharing Designs Of Metal Lathe Saddles Among Engineers And Manufacturers?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, there are some popular file formats for sharing designs. We often use DXF (Drawing Exchange Format) and STL (Stereolithography) files. These formats work well when sharing designs because many people can open them. You can easily send these files to engineers and manufacturers to help them understand your design.”}},{“@type”: “Question”,”name”: “How Can Cad Files For Metal Lathe Saddles Be Optimized For Printing Or Cnc Machining Processes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make CAD files for metal lathe saddles better for printing or CNC machining, we should keep the design simple. Use clear shapes and avoid small details that might be hard to print or cut. We can also check the sizes to make sure they fit well together. Lastly, we need to save the file in a format that the printer or machine can understand easily. This way, we get strong and accurate parts!”}}]}