Have you ever seen a metal lathe in action? It’s like watching a magic trick performed by a machine! A lathe can shape metal with amazing precision. But did you know that you can enhance your lathe experience with CAD files? These files help you design and create specific parts for your projects.

Many hobbyists and professionals use lathe CAD files to make their work much easier. Imagine being able to customize metal lathe tools just for your needs. How cool is that? You can turn ideas into reality at your fingertips.

In this article, we will explore the world of lathe CAD files and how they can take your metalworking to the next level. Join us as we uncover the benefits of using these innovative tools. Who knows? You might find a new project or even a hidden talent!

Lathe Cad Files: Essential Metal Lathe Tools For Precision

Exploring Lathe CAD Files and Metal Lathe Tools

Lathe CAD files are essential for creating precise tools. Imagine designing a perfect part for your project. Metal lathe tools make this possible by shaping materials accurately. These files help you visualize your designs before cutting metal. Did you know that using CAD can save time and reduce mistakes? By utilizing these files, you can enhance your skills and craft better projects. It’s a simple way to bring your ideas to life with metal lathe tools!Understanding Lathe CAD Files

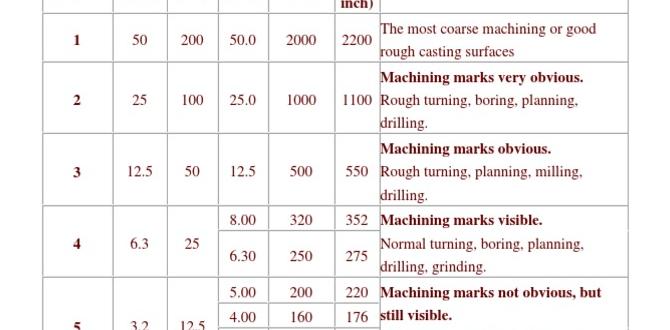

Definition and purpose of CAD files in metalworking. Benefits of using CAD files for lathe tool design.CAD files in metalworking are digital blueprints. They help create parts for machines, like lathes. Utilizing these files allows designers to see how things will fit together. The main benefits of using CAD files include:

- Accuracy: CAD makes precise designs.

- Time-saving: It speeds up the design process.

- Easy changes: Modify designs simply.

Using CAD for lathe tool design is smart. It helps workers become more efficient and creative.

What are the benefits of CAD files?

Benefits include saving time, increasing accuracy, and allowing easy modifications. Designing becomes fun and useful with these tools.

Popular CAD Software for Lathe Tool Design

Comparative analysis of software options (AutoCAD, SolidWorks, Fusion 360). Factors to consider when choosing CAD software for lathe projects.Choosing the right CAD software is important for designing lathe tools. Three popular options are AutoCAD, SolidWorks, and Fusion 360. Each has unique features. Consider your needs first. Here’s a quick comparison:

- AutoCAD: Great for 2D drawings.

- SolidWorks: Best for 3D modeling.

- Fusion 360: Combines design and collaboration easily.

Think about your project’s requirements and your skill level when selecting software. User-friendliness, cost, and features should guide your choice.

What should I consider when choosing CAD software?

Key factors include:

- Usability

- Cost-effectiveness

- Features

- Support and resources

How to Create CAD Files for Metal Lathe Tools

Stepbystep guide to designing lathe tools using CAD software. Common pitfalls to avoid during the design process.Creating CAD files for metal lathe tools can be fun! Start with these easy steps:

- Choose your CAD software.

- Draw basic shapes for your tool.

- Add details like dimensions and angles.

- Check for errors before saving your file.

Avoid these common mistakes:

- Skipping the design plan.

- Not double-checking measurements.

- Ignoring tool material properties.

With practice, you’ll design amazing tools!

What should I avoid when designing CAD files for metal lathe tools?

Avoid rushing your designs, skipping measurements, and using incorrect materials. Take your time to get it right!

Where to Find Lathe CAD Files Online

Recommended websites and repositories for downloading CAD files. Tips for assessing the quality and compatibility of downloaded files.Finding lathe CAD files online is easier than ever. Many websites offer free downloads. Popular sites include:

- GrabCAD

- Thingiverse

- CAD Blocks

- TurboSquid

Check if the files match your software. Look for reviews to assess their quality. Some files may need tweaks to work properly. Always download from trusted sources to avoid issues.

Where can I download free CAD files?

You can find free CAD files on many websites. GrabCAD and Thingiverse are great places to start. They have large collections for various needs.

Best Practices for Using CAD Files in Metalworking

Techniques for optimizing CAD files for production. Importance of reviewing and testing designs before machining.Using CAD files in metalworking can be both fun and a bit tricky. First, always review your designs. Think of it as double-checking your homework before turning it in—nobody wants a surprise test! Testing your CAD files can save time and materials, like avoiding that embarrassing walk of shame to the scrap bin. Here are some techniques to optimize those files:

| Technique | Description |

|---|---|

| Minimize Complexity | Keep designs simple to reduce errors and speed up production. |

| Layer Organization | Use layers wisely for better visibility and editing. |

| Check Units | Make sure you’ve set the correct units to avoid major hiccups. |

With these best practices, you can make your metalworking journey smoother and maybe even a bit more fun. Remember, a good design is the first step to a great project!

Case Studies: Successful Projects Using Lathe CAD Files

Examples of industry applications utilizing CADdesigned lathe tools. Lessons learned from these projects and their impact on efficiency.Many industries use lathe CAD files to improve their work. These projects have shown great results. For example, automotive companies use custom lathe tools to make parts faster. This saves time and reduces waste.

- In aerospace, lathe designs help create strong and lightweight components.

- Manufacturing businesses can increase production by 30% with effective lathe tools.

Learning from these cases means better designs. Improvements lead to less material use and faster results. Overall, using lathe CAD files boosts efficiency greatly.

What industries benefit from CAD-designed lathe tools?

Industries such as automotive, aerospace, and manufacturing benefit significantly from CAD-designed lathe tools. They help create precise parts and improve production speed.

Future Trends in Lathe Tools and CAD Technology

Emerging technologies impacting lathe tool design. Predictions for the evolution of CAD software in the metalworking industry.New tech is changing how we create lathe tools. 3D printing lets us make parts faster and more accurately. With better materials, tools can last longer without breaking. CAD software is getting smarter too. It will be easier to design and test tools before making them. Some say, “Before the end of this decade, CAD will be so advanced, it may just design itself!” Here’s how these trends could shape the future:

| Trend | Description |

|---|---|

| 3D Printing | Creates parts quickly with less waste. |

| Smart CAD Software | Uses AI to improve design accuracy. |

| Advanced Materials | Longer-lasting tools made from new compounds. |

Conclusion

In summary, lathe CAD files help you design and create tools for metalworking. These files make it easy to visualize your projects. With the right knowledge, you can enhance your skills and create amazing things. We encourage you to explore more about lathe tools and practices. Dive into resources or tutorials to start building your own projects today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Cad Files And Metal Lathe Tools:Sure! Lathe CAD files help us plan and design parts we want to make with a lathe. A lathe is a tool that spins metal to shape it. We use metal lathe tools like cutting tools to make precise shapes. These files help us know exactly how our finished piece will look. It’s like a blueprint for our project!

Sure! Just send me the question you’d like me to answer, and I’ll help you with that!

What Are The Best Cad Software Programs For Designing Metal Lathe Tools And Components?Some great CAD (Computer-Aided Design) software for making metal lathe tools are AutoCAD, SolidWorks, and Fusion 360. AutoCAD is easy to use for beginners. SolidWorks helps you build 3D models easily. Fusion 360 combines design and engineering, making it perfect for projects. You can choose any of these to create your metal tools!

How Can I Find Or Create Cad Files Specifically For Custom Metal Lathe Tool Fixtures?To find or create CAD files for metal lathe tool fixtures, you can start by searching online. Websites like Thingiverse and GrabCAD have free designs you can use. You can also use CAD software, like TinkerCAD or Fusion 360, to make your own. Just sketch your idea and save it as a CAD file. If you need help, ask a friend or watch tutorials online!

What Are The Common File Formats Used For Sharing Cad Designs Of Metal Lathe Tools?When sharing CAD designs of metal lathe tools, we often use file formats like DWG, DXF, and STL. DWG is a drawing file that helps with 2D and 3D designs. DXF stands for Drawing Exchange Format and is good for sharing drawings between different programs. STL is used mainly for 3D printing. These formats help everyone see and use the designs easily.

How Do I Convert A Cad Model Of A Metal Lathe Tool Into A Format Suitable For Cnc Machining?To convert a CAD model into a format for CNC machining, you can follow these steps. First, open your CAD software and load your model. Next, choose the option to export or save the file. Select a format like DXF or STL, which works well for CNC machines. Finally, save the file and make sure to check if it’s ready for the CNC machine.

What Features Should I Consider When Downloading Or Creating Cad Files For A Metal Lathe Tool Design?When you download or create CAD files for a metal lathe tool design, look for a few important features. Make sure the file is the right size and shape for your project. Search for designs that are clear and easy to understand. Check if the file is compatible with your CAD software. Lastly, ensure it shows how the tool will work and fit together.