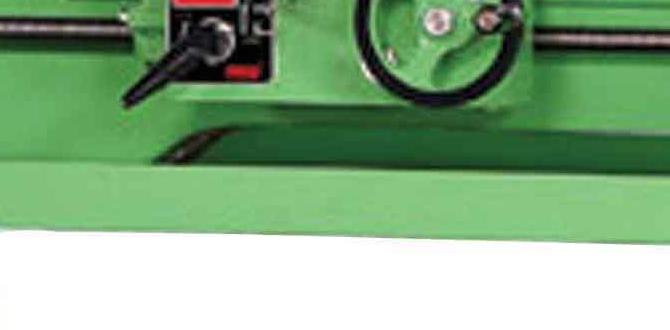

Have you ever wondered how precise tools are made? In the world of metalworking, lathe calibration plays a key role. A lathe is a machine that shapes metal into different forms. But how do we make sure it works perfectly every time?

Imagine trying to bake a cake. If your measurements are off, the cake won’t turn out right. The same idea applies to a lathe. Proper calibration ensures it cuts accurately. When a lathe is automated, this process becomes faster and easier.

Did you know that modern metal lathes can adjust themselves? That’s right! Automation helps reduce human error. This means better products and safer work. As we dive into the topic, you’ll learn more about why lathe calibration matters and how automation is changing the game.

Lathe Calibration: Optimizing Metal Lathe Automation Process

Lathe Calibration and Automation

Calibrating a metal lathe is essential for precision machining. Proper calibration ensures that the lathe functions accurately, preventing mistakes in production. Have you ever noticed how a tiny error can cause big problems in metal work? Automation takes this a step further by using technology to enhance efficiency. Imagine a lathe that adjusts itself automatically! This innovation saves time and reduces human error, making metalworking smarter and faster. Embracing lathe calibration and automation can truly elevate your projects.Understanding Lathe Calibration

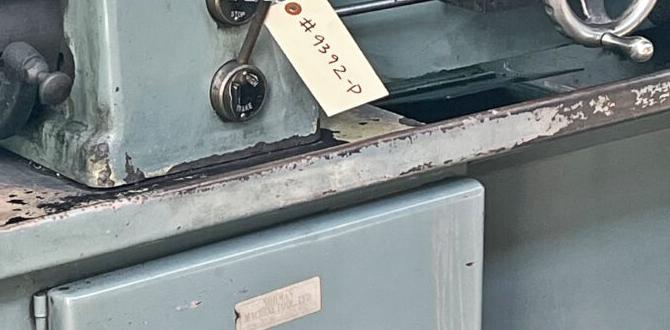

Definition and importance of lathe calibration in metalworking.. Key factors influencing precision and accuracy in lathe operation..Lathe calibration means adjusting the machine to work correctly. This step is key in metalworking as it ensures parts are made accurately. If the lathe is not calibrated well, pieces may be too big or too small. The right calibration can save time and materials.

Important factors influencing precision include:

- Machine setup

- Tool wear

- Material properties

- Environmental conditions

Together, these elements help create high-quality metal parts.

What is the benefit of lathe calibration?

Lathe calibration helps prevent mistakes, reduces waste, and enhances overall precision.

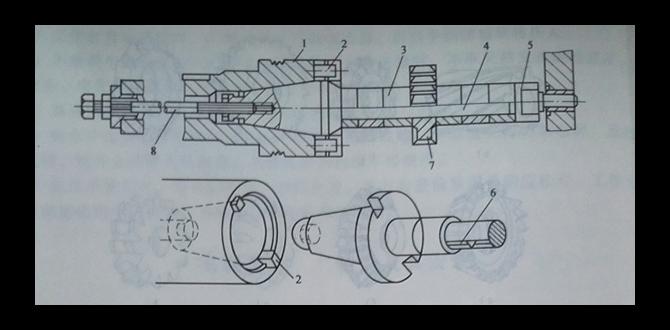

Tools and Equipment for Lathe Calibration

Essential tools required for effective lathe calibration.. Advanced equipment that enhances calibration accuracy..To calibrate a lathe effectively, you’ll need key tools and advanced equipment. Essential tools include:

- Micrometers for measuring small distances.

- Dial indicators to check accuracy.

- Calibration blocks for precise adjustments.

Advanced equipment can greatly enhance accuracy. Items like laser alignment tools and digital readouts offer precise measurements that help keep your lathe running smoothly.

What tools do I need for lathe calibration?

For lathe calibration, you need micrometers, dial indicators, and calibration blocks. These basic tools ensure that your lathe works correctly and maintains its accuracy.

The Calibration Process Step-by-Step

Detailed steps for performing lathe calibration.. Common pitfalls and how to avoid them..Calibrating a lathe can feel like solving a puzzle, but don’t worry, it’s straightforward! First, check the levels and align the lathe properly. Next, adjust the tool settings to ensure they fit snugly. Always measure your cuts carefully to guarantee precision. One common mistake is not checking the spindle rotation; it’s like trying to bake without the oven preheating! Avoid it by remembering: measure twice, cut once!

| Step | Tip |

|---|---|

| Level the lathe | Use a bubble level for accuracy. |

| Adjust tool settings | Fit tools snugly to avoid wobbles. |

| Measure your cuts | Be precise, like a cat stalking a mouse. |

Benefits of Regular Lathe Calibration

Impact on product quality and consistency.. Longterm cost savings and efficiency improvements..Regularly checking a lathe helps keep high quality in the products. It helps machines work better and create consistent results. This means fewer mistakes and less waste. Over time, this care saves money and boosts productivity. When machines run smoothly, they use energy wisely. This leads to better profits and a brighter future for the business.

How does regular lathe calibration impact product quality?

It ensures products are made correctly and with fewer errors. Calibration creates consistency, making sure every item meets the same standards.

What are the long-term cost savings and efficiency improvements?

- Fewer repairs and replacements.

- Less wasted material.

- Higher production rates.

These factors lead to significant savings and better overall performance.

Integrating Automation into Lathe Calibration

How automation tools can enhance calibration accuracy.. Case studies of successful automation in metal lathe calibration..Using automation tools can greatly improve the accuracy of lathe calibration. These tools help machines run more smoothly and make precise measurements. For instance, automated systems can quickly identify any errors. This means we can fix problems faster and keep machines working well.

Many companies have successfully integrated automation into metal lathe calibration. They report fewer mistakes and more consistent results. Here are a few examples:

- A factory reduced errors by 30% with automated calibration systems.

- A workshop increased its production speed by 40% after applying automation techniques.

Automation makes calibration easier and better. It gets machines back to work quickly, ensuring everyone stays productive.

How does automation improve lathe calibration accuracy?

Automation tools make measurements precise and fast, reducing human error and increasing reliability.

Best Practices for Lathe Calibration and Automation

Recommended practices to ensure optimal lathe performance.. Guidelines for regular maintenance and checks..To keep your lathe working its best, follow some easy practices. Regular checks help spot issues before they become big problems. Here are key tips:

- Check the spindle alignment often.

- Clean the machine after each use.

- Lubricate moving parts as needed.

- Inspect belts and gears regularly.

These steps keep your metal lathe accurate and running smoothly. Remember, a little care goes a long way in making your lathe last longer!

What is a quick way to improve lathe performance?

Regularly calibrate your lathe before use. This simple step helps maintain precision and reduces wear.

Trends and Innovations in Lathe Calibration and Automation

Emerging technologies shaping the future of lathe calibration.. Predictions for the evolution of metal lathe automation..New tools are shaking up lathe calibration and automation. With smart sensors, machines can now talk to each other! This means they calibrate themselves without human help. Imagine a robot saying, “I’m fine, thanks!” to a technician. Predictions show that as AI improves, metal lathes will work faster and with tiny errors. This could save factories loads of time and cash. Get ready for a robot takeover, but hopefully, they won’t ask for lunch breaks!

| Trend | Description |

|---|---|

| Smart Sensors | Improves self-calibration directly. |

| AI Integration | Enhances efficiency in metal lathes. |

| Remote Monitoring | Allows real-time adjustments from anywhere. |

Conclusion

In conclusion, lathe calibration improves accuracy in metal lathe automation. Proper calibration ensures your projects are precise and efficient. You can enhance your skills by practicing regular checks and exploring automation tools. Take time to learn more about these topics, and you’ll become a better machinist. Let’s keep improving together and make our work easier and more precise!FAQs

What Are The Key Steps Involved In Calibrating A Metal Lathe To Ensure Precision In Machining Operations?To calibrate a metal lathe, you first make sure it’s level on the ground. Next, check the tool holder and adjust it if needed. You then measure the distance from the tool to the workpiece to ensure it’s correct. After that, we test the lathe by running it and checking if it cuts straight. Finally, keep adjusting until everything works just right for precise machining.

How Can Automation Technologies Enhance The Calibration Process Of Metal Lathes?Automation technologies can make calibrating metal lathes easier and faster. They use machines to check and adjust the lathe settings automatically. This means you don’t have to do it by hand, which saves time. The machines can also help find mistakes and fix them right away. With automation, we get better results and can make things more accurately.

What Common Issues Can Arise During The Calibration Of A Metal Lathe, And How Can They Be Resolved?When you calibrate a metal lathe, you might face some common problems. One issue is that the machine may not cut straight. To fix this, you can adjust the alignment carefully. Another problem is the tool not fitting properly. You should check and tighten any loose parts. Lastly, make sure your measurements are accurate. Regularly check them to keep everything working well.

What Types Of Sensors And Measurement Tools Are Most Effective For Monitoring The Accuracy Of A Lathe During Automated Operations?To check a lathe’s accuracy, we can use different sensors and tools. First, we can use laser sensors to measure distances very precisely. Then, we can use dial indicators to see if parts are making the right shapes. There are also cameras that help us look closely at the work. Together, these tools help us ensure the lathe works correctly during automated tasks.

How Does Regular Calibration Contribute To The Overall Efficiency And Quality Of Production In Automated Metalworking Environments?Regular calibration helps machines work better and more accurately. When we calibrate, we make sure the tools are set correctly. This means the parts we make will fit perfectly and not waste materials. With better accuracy, production runs smoothly and quickly. In the end, we get high-quality products and save time!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Key Steps Involved In Calibrating A Metal Lathe To Ensure Precision In Machining Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate a metal lathe, you first make sure it’s level on the ground. Next, check the tool holder and adjust it if needed. You then measure the distance from the tool to the workpiece to ensure it’s correct. After that, we test the lathe by running it and checking if it cuts straight. Finally, keep adjusting until everything works just right for precise machining.”}},{“@type”: “Question”,”name”: “How Can Automation Technologies Enhance The Calibration Process Of Metal Lathes? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Automation technologies can make calibrating metal lathes easier and faster. They use machines to check and adjust the lathe settings automatically. This means you don’t have to do it by hand, which saves time. The machines can also help find mistakes and fix them right away. With automation, we get better results and can make things more accurately.”}},{“@type”: “Question”,”name”: “What Common Issues Can Arise During The Calibration Of A Metal Lathe, And How Can They Be Resolved? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you calibrate a metal lathe, you might face some common problems. One issue is that the machine may not cut straight. To fix this, you can adjust the alignment carefully. Another problem is the tool not fitting properly. You should check and tighten any loose parts. Lastly, make sure your measurements are accurate. Regularly check them to keep everything working well.”}},{“@type”: “Question”,”name”: “What Types Of Sensors And Measurement Tools Are Most Effective For Monitoring The Accuracy Of A Lathe During Automated Operations? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To check a lathe’s accuracy, we can use different sensors and tools. First, we can use laser sensors to measure distances very precisely. Then, we can use dial indicators to see if parts are making the right shapes. There are also cameras that help us look closely at the work. Together, these tools help us ensure the lathe works correctly during automated tasks.”}},{“@type”: “Question”,”name”: “How Does Regular Calibration Contribute To The Overall Efficiency And Quality Of Production In Automated Metalworking Environments? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Regular calibration helps machines work better and more accurately. When we calibrate, we make sure the tools are set correctly. This means the parts we make will fit perfectly and not waste materials. With better accuracy, production runs smoothly and quickly. In the end, we get high-quality products and save time!”}}]}