Have you ever struggled to turn a lathe carriage handwheel? It can be frustrating when the handwheel just doesn’t work right. Sometimes, this happens because it’s worn out or damaged. Imagine trying to finish an important project with a faulty tool. You might feel stuck and worried.

Replacing a lathe carriage handwheel can seem tricky. But it doesn’t have to be! Many people find that by learning a few simple steps, they can do it themselves. Want to know a fun fact? Most lathe handwheels are designed for easy replacement, making this task quicker than you think.

In this article, we’ll explore the process of lathe carriage handwheel replacement. You’ll learn why it’s important and how to do it right. So, are you ready to get started? Let’s dive in and make your lathe work like new again!

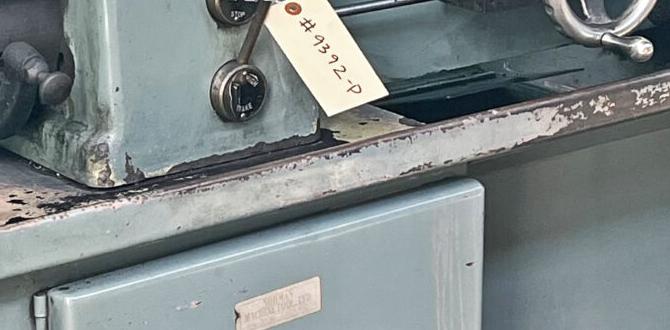

Lathe Carriage Handwheel Replacement: A Comprehensive Guide

Lathe Carriage Handwheel Replacement

Replacing a lathe carriage handwheel can be simple and rewarding. Have you ever struggled to turn a worn-out handwheel? This guide shows you how to choose the right replacement part easily. Proper tools and steps make the job faster. Did you know that a new handwheel can improve your machine’s precision? Learning to replace it can save time and frustration in your projects. Get your lathe running smoothly with a quick handwheel fix!Understanding the Lathe Carriage Handwheel

Definition and function of the handwheel in lathe operations. Importance of maintenance for optimal performance.The handwheel is a key part of a lathe machine. It helps you move the carriage smoothly. This movement is vital for shaping materials like wood and metal. Keeping the handwheel in good shape is essential. Regular maintenance ensures it works well and lasts longer. Proper care prevents problems during your projects, making your work easier and more enjoyable.

What does the lathe carriage handwheel do?

The handwheel controls the position of the cutting tool. It allows precise adjustments while working. Without it, the lathe would be hard to use. Users might struggle with accuracy and create poor quality work.

Why is maintenance important?

- It ensures smooth operation.

- It increases the lifespan of the lathe.

- It prevents costly repairs down the road.

Common Signs of Handwheel Wear and Tear

Identifying physical damage and operational issues. Impact of worn handwheels on lathe performance.When using a lathe, noticing some signs on the handwheel is important. If it feels wobbly or turns with a grating sound, it might be tired. Look for cracks or chips. These are clear signs of physical damage. Operational issues? If it’s tough to make precise adjustments, your lathe’s performance might splutter like a sputtering engine! Keeping an eye on these signs can save you from headaches and keep your machine running smoothly.

| Signs of Wear | Impact on Performance |

|---|---|

| Wobbly Handwheel | Poor Precision |

| Cracks or Chips | Increased Risk of Breakage |

| Noisy Operation | Difficulty in Adjustments |

Tools and Materials Needed for Replacement

List of essential tools (e.g., wrenches, screwdrivers). Types of replacement handwheels available in the market.Getting ready to replace your lathe carriage handwheel? First, gather your tools! You’ll need some basic wrenches and screwdrivers. Don’t forget your trusty pliers – they come in handy for those stubborn screws! It’s like preparing for a DIY adventure! But wait, what about the handwheels? There are different types available. Some are plastic, while others are made of metal. Check out the table below to see your options!

| Type | Material | Price Range |

|---|---|---|

| Standard Handwheel | Plastic | $10 – $20 |

| Heavy-Duty Handwheel | Metal | $20 – $50 |

| Custom Handwheel | Aluminum | $30 – $60 |

Step-by-Step Replacement Process

Detailed instructions on removing the old handwheel. Guidelines for installing the new handwheel.First, let’s tackle that old handwheel! You’ll need a wrench and maybe a snack for later—this is serious business! Start by unscrewing the bolts holding the handwheel in place. Make sure to keep them in a safe spot; they have a tendency to play hide and seek. Once it’s loose, give it a gentle wiggle and it should pop right off.

Now, it’s time for the new star of the show! Align your new handwheel with the spindle and get those bolts ready. Tighten them snugly, but don’t go all Hulk on it! A firm grip will do. Double-check to ensure everything is in place. Voila! You’ve replaced your handwheel like a pro. Time to show off those spinning skills!

| Step | Action |

|---|---|

| 1 | Unscrew old handwheel |

| 2 | Pop it off gently |

| 3 | Align new handwheel |

| 4 | Tighten the bolts |

| 5 | Check for snug fit |

Maintenance Tips for Longevity

Routine checks to prevent future issues. Best practices for cleaning and lubrication.Keeping your tools happy is key to smooth operations. Regular checks stop problems before they start! Look for any loose screws or worn-out parts. If something looks off, fix it right away. For cleaning, use a soft cloth and avoid harsh chemicals. A little soap and water never hurt anyone! Lubrication is like a spa day for your lathe. Oil the moving parts to keep things running smoothly. Remember, a well-maintained lathe is a happy lathe!

| Task | Frequency | Tip |

|---|---|---|

| Check Screws | Weekly | Look for wiggles! |

| Clean | Daily | Soft cloth only! |

| Lubricate | Bi-weekly | Oil is your friend! |

Choosing the Right Replacement Handwheel

Factors to consider (size, material, compatibility). Recommended brands and models.Choosing a new handwheel can be tricky, but it can also be fun—like picking toppings for pizza! Start with the size. Will it fit your lathe? Next, consider the material. You want something strong but not too heavy. Lastly, check compatibility. Not every wheel fits every machine, much like socks don’t fit on your pet gerbil. Recommended brands include Grizzly and Jet, known for their quality. Here’s a handy table to guide you:

| Brand | Model | Size | Material |

|---|---|---|---|

| Grizzly | H1748 | 6″ | Aluminum |

| Jet | 733900 | 8″ | Steel |

Frequently Asked Questions

Common concerns about handwheel replacement. Troubleshooting tips related to handwheel issues.Many people worry about replacing their lathe carriage handwheel. Here are common concerns and troubleshooting tips to guide you.

How do I know if my handwheel needs replacement?

If the handwheel feels loose or doesn’t turn smoothly, it might need a new one. Check for cracks or wear in the wheel.

What can I do if my handwheel is stuck?

If it’s stuck, try applying some oil around the area. This can help loosen it up. If that doesn’t work, check for debris blocking the wheel.

Common issues and tips:

- Worn bearings: Replace them if they are noisy or rough.

- Alignment problems: Make sure the handwheel is aligned correctly.

- Rust issues: Clean the area and oil to prevent rust.

Understanding these tips can help you maintain your lathe better. Taking care of your tools leads to smoother projects!

DIY vs. Professional Replacement: Pros and Cons

Advantages of doing it yourself. When to consider professional help.Doing a project yourself can be fun and rewarding. You might save money and learn new skills. Here are some good points:

- You gain experience that helps with future tasks.

- It can be more budget-friendly than hiring someone.

- You have the freedom to work on your own schedule.

However, sometimes it is better to ask for help. If the task is too hard or risky, consider getting a pro. Think about these times:

- If you lack the right tools.

- When time is tight and the job is tricky.

- If you care about a perfect look and finish.

When should I seek professional help?

If the task seems beyond your skill level, hiring an expert can save time and ensure the job is done right.

Additional Resources and References

Recommended reading and online tutorials for further assistance. Links to community forums and expert advice.Finding the right information can make your lathe carriage handwheel replacement easier. Here are some great places to learn more:

- Books: Look for guides on lathe maintenance.

- Online Tutorials: Check YouTube for step-by-step videos.

- Community Forums: Join forums like Reddit or woodworking sites for advice.

- Expert Blogs: Read blogs from experienced machinists for tips.

These resources can help you learn faster and solve problems with your project.

What are some recommended resources?

For learning, books and online tutorials are top choices. Also, consider joining a community forum for support.

Conclusion

In conclusion, replacing your lathe carriage handwheel can improve your tool’s performance. You should check for wear and tear regularly. If you notice issues, look for replacement parts soon. This will keep your lathe running smoothly. For more tips and guides, consider reading more articles on maintenance. Remember, a well-cared-for lathe lasts longer and works better!FAQs

What Are The Common Signs That Indicate The Need For A Lathe Carriage Handwheel Replacement?You can tell it’s time to replace the lathe carriage handwheel if it feels loose or wobbly. If it doesn’t move smoothly, that’s another sign. You might also notice strange noises when you turn it. Lastly, if it has cracks or damage, it’s best to replace it.

How Do I Properly Remove And Replace The Handwheel On A Lathe Carriage?To remove the handwheel, first, find the small screw or bolt that holds it in place. Use a wrench or screwdriver to take out the screw. Next, gently pull off the handwheel from the lathe carriage. To put it back, line it up and push it on. Finally, screw the bolt back to keep it secure.

What Tools And Materials Are Necessary For Replacing The Lathe Carriage Handwheel?To replace the lathe carriage handwheel, you need a few tools and materials. First, get a screwdriver. A wrench will help too. You will also need the new handwheel part. Make sure to have some clean rags for any dirt or oil. Finally, have a flashlight handy to see better!

Are There Specific Models Of Lathes That Require Unique Handwheel Replacement Procedures?Yes, some lathes need special steps to change the handwheel. Each model can be different. You should check the owner’s manual for exact instructions. This helps you do it safely and correctly. If you’re unsure, ask someone for help.

How Can I Ensure That The New Handwheel Is Compatible With My Lathe Model?To make sure the new handwheel fits your lathe, first check your lathe model. Look at the owner’s manual for details about size and design. You can also visit the manufacturer’s website or contact them for help. Finally, compare the measurements of the new handwheel to your lathe to see if they match.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate The Need For A Lathe Carriage Handwheel Replacement? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can tell it’s time to replace the lathe carriage handwheel if it feels loose or wobbly. If it doesn’t move smoothly, that’s another sign. You might also notice strange noises when you turn it. Lastly, if it has cracks or damage, it’s best to replace it.”}},{“@type”: “Question”,”name”: “How Do I Properly Remove And Replace The Handwheel On A Lathe Carriage? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To remove the handwheel, first, find the small screw or bolt that holds it in place. Use a wrench or screwdriver to take out the screw. Next, gently pull off the handwheel from the lathe carriage. To put it back, line it up and push it on. Finally, screw the bolt back to keep it secure.”}},{“@type”: “Question”,”name”: “What Tools And Materials Are Necessary For Replacing The Lathe Carriage Handwheel? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To replace the lathe carriage handwheel, you need a few tools and materials. First, get a screwdriver. A wrench will help too. You will also need the new handwheel part. Make sure to have some clean rags for any dirt or oil. Finally, have a flashlight handy to see better!”}},{“@type”: “Question”,”name”: “Are There Specific Models Of Lathes That Require Unique Handwheel Replacement Procedures? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, some lathes need special steps to change the handwheel. Each model can be different. You should check the owner’s manual for exact instructions. This helps you do it safely and correctly. If you’re unsure, ask someone for help.”}},{“@type”: “Question”,”name”: “How Can I Ensure That The New Handwheel Is Compatible With My Lathe Model? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To make sure the new handwheel fits your lathe, first check your lathe model. Look at the owner’s manual for details about size and design. You can also visit the manufacturer’s website or contact them for help. Finally, compare the measurements of the new handwheel to your lathe to see if they match.”}}]}