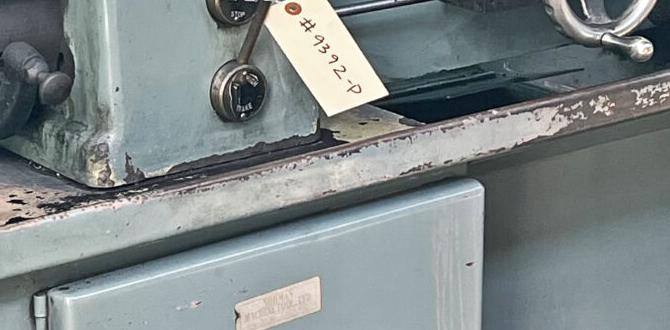

Have you ever wondered how machines stay so precise? One key part is the **lathe carriage**. It helps move tools smoothly while working on metal or wood. A problem can arise when the **rack gear** wears out. This wear can lead to mistakes in cutting, which no one wants.

Imagine trying to steer a bike with wobbly handlebars. It doesn’t feel good, right? That’s how a worn rack gear feels for a lathe. The machine can’t perform at its best, and it could even break down. But what causes this wear, and how can we test for it?

In this article, we will explore the **lathe carriage rack gear wear test**. We’ll learn how to spot problems and keep machines running smoothly. Let’s dive into the world of gears, tests, and how to prevent big issues!

Lathe Carriage Rack Gear Wear Test: Ensuring Precision Performance

Lathe Carriage Rack Gear Wear Test

Understanding how to test the wear on lathe carriage rack gears is vital for smooth machining. Regular wear can lead to misalignment and poor performance. You may wonder, what causes this wear? Factors like material quality and lubrication play a role. Interestingly, a simple scratch can lead to bigger problems later. By examining wear patterns, users can predict gear life and schedule maintenance. Keeping gears in top shape ensures safer and more efficient machining.Importance of Wear Testing for Rack Gears

Impact of gear wear on machining accuracy. Common issues caused by wornout gears.Wear testing is crucial for rack gears. Worn gears can have serious effects on machining accuracy. They may lead to:

- Inaccurate cuts

- Poor surface finish

- Increased vibrations

- Shortened tool life

These issues can slow down production and increase costs. Regular wear testing helps find problems early. This way, we can fix them before they cause major trouble.

Why is gear wear testing important?

Gear wear testing is vital. It helps maintain precision and quality in machining. By catching wear early, you can avoid expensive repairs and delays.

Setting Up a Wear Test

Required equipment and materials for testing. Stepbystep guide to preparing the lathe for testing.To begin the wear test, gather the right tools. You’ll need a lathe, a gear measuring device, and safety gear like goggles. Here’s how to prepare:

- Check the lathe’s condition.

- Clean the machine and remove any old gears.

- Install the new gear carefully.

- Set up the measuring device to monitor wear.

- Finally, calibrate the machine for accurate testing.

This setup ensures a smooth and effective wear test. Always remember safety first while you work.

What equipment do I need for the wear test?

For a successful lathe carriage rack gear wear test, you’ll need the following: lathe machine, measuring tools, lubricant, and safety gear.

Conducting the Wear Test

Detailed procedure for executing the wear test. Best practices for consistent and reliable results.To carry out the wear test, start with a clean lathe carriage. Ensure all parts are in good shape. Use a standard gear to check for any changes. Run the lathe at a normal speed for a set time. Measure wear using precise tools. Keep records of all results.

For consistent results, follow these best practices:

- Conduct tests in a controlled environment.

- Repeat tests to confirm findings.

- Use the same materials each time.

- Take measurements at the same spots.

What are the key benefits of conducting a wear test?

Conducting a wear test helps ensure your lathe functions well and lasts longer. It identifies issues early and saves you money in repairs.

Analyzing Wear Test Results

Methods for data collection and analysis. Interpreting wear patterns and their implications.Collecting and analyzing data is key to understanding gear wear in lathe carriages. One popular method is using optical measurement systems. They capture images of wear patterns, making it easier to see what’s really going on. Analyzing these patterns helps us figure out how to extend the gear’s life. For example, if we notice uneven wear on one side, we can tweak the setup or check for alignment issues. Think of it like finding out why your shoe wears out faster on one side – it helps to avoid “lopsided” problems in the future!

| Wear Pattern Type | Implication |

|---|---|

| Uniform Wear | Good maintenance. |

| Uneven Wear | Possible alignment issues. |

| Excessive Wear | Need for urgent inspection. |

Maintenance Strategies to Mitigate Gear Wear

Preventive maintenance practices. Recommended lubrication techniques and intervals.To keep your gears happy and working well, preventive maintenance is a must. Regular checks can stop issues before they start. Think of it as a yearly trip to the dentist, but for your machine! Make sure to wipe and lubricate your lathe every so often. Proper lubrication helps reduce friction and wear. Here’s a simple table for guidance on lubrication intervals:

| Component | Lubrication Interval |

|---|---|

| Gearbox | Every 50 hours |

| Carriage | Every 100 hours |

| Lead Screw | Every 25 hours |

By following these tips, you can help reduce gear wear and keep your lathe performing like a champ. Remember, a happy lathe is like a pet that doesn’t bite!

Case Studies on Gear Wear Testing

Examples of wear test outcomes in various industries. Lessons learned and improvements made.Many companies have tested gear wear in different areas. For example, in the automotive industry, wear tests showed that higher-quality materials last longer. In construction, tests helped improve equipment durability. Lessons learned included using better lubricants and design tweaks for gear systems. Here are some key points from studies:

- Improved gear shape reduced wear.

- Regular maintenance extended gear life.

- Advanced materials showed less wear.

These tests help companies reduce costs and improve machinery efficiency.

What are the outcomes of gear wear tests?

Gear wear tests reveal important data about material strength and lifespan, showing how to make gears last longer.

Future Trends in Gear Wear Testing

Emerging technologies in wear testing. Predictions for shifts in testing methodologies.New tools and methods are shaping the future of gear wear testing. Emerging technologies, like AI and machine learning, help in understanding how gears wear out. These tools can predict when a gear might fail. Experts believe testing methods will change in these ways:

- More automation in testing processes.

- Using sensors for real-time wear monitoring.

- More focus on environmental impacts.

With these trends, we can improve gear performance and safety.

What are the benefits of advanced methods in wear testing?

Advanced methods can help detect problems early and save money on repairs. They also increase gear lifespan and enhance overall equipment reliability.

Conclusion

In conclusion, the lathe carriage rack gear wear test helps ensure our machines work well. You learn how wear affects performance. This knowledge helps you maintain equipment better and avoid costly repairs. We encourage you to explore more about gear maintenance and watch for wear signs. Understanding these concepts makes you a more skilled user of machines. Happy learning!FAQs

Here Are Five Related Questions On The Topic Of Lathe Carriage Rack Gear Wear Testing:Lathe carriage rack gear wear testing checks how much the gear wears out over time. We use special tools to measure the gear and see if it still works well. This testing helps us know when to replace parts. It keeps machines running smoothly and safely. You help make sure everything is in good shape!

Sure! Please provide the question you would like me to answer, and I’ll help you with it.

What Are The Primary Indicators Of Wear In A Lathe Carriage Rack Gear During Testing?When testing a lathe carriage rack gear, you might notice some signs of wear. Look for missing teeth or grooves on the gear. You may also see uneven movement as the gear turns. Listen for strange sounds, like grinding or clanking, which can indicate problems. Finally, check for rough spots that can make it hard for the gear to turn smoothly.

How Can The Accuracy And Precision Of Lathe Operations Be Affected By The Wear Of Carriage Rack Gears?When the carriage rack gears wear out, they do not fit together as well. This can cause the lathe, a tool that shapes metal or wood, to move less smoothly. If the lathe doesn’t move correctly, it can make mistakes, leading to parts that are not always the same size or shape. This means your work may be less accurate and precise, which is important for good results. Taking care of the gears helps keep your work looking great!

What Methods Are Commonly Used To Assess The Wear Characteristics Of Rack Gears In Lathe Carriages?We can check how much rack gears in lathe carriages wear out using a few methods. First, we look for signs of damage, like scratches or dents. Then, we might measure the gears to see if they still fit together well. We also listen for weird sounds when the lathe runs. Lastly, we can use a special tool to see how tightly the gears grip each other.

How Does The Material Composition Of A Rack Gear Influence Its Wear Resistance And Longevity In Lathe Applications?The material of a rack gear is very important. If it’s strong and tough, it lasts longer. Good materials resist wear, which means they don’t break down easily. For lathe machines, this helps everything work smoothly. So, choosing the right material helps you keep using the gear without problems for a long time.

What Preventative Maintenance Practices Can Be Implemented To Reduce Wear On Lathe Carriage Rack Gears?To help keep lathe carriage rack gears from wearing out, we can take some simple steps. First, always clean the gears regularly to remove dust and dirt. Next, we should oil the gears to keep them moving smoothly. We can also check for any loose parts and tighten them. Finally, use the lathe carefully to avoid putting too much pressure on the gears.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Carriage Rack Gear Wear Testing:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe carriage rack gear wear testing checks how much the gear wears out over time. We use special tools to measure the gear and see if it still works well. This testing helps us know when to replace parts. It keeps machines running smoothly and safely. You help make sure everything is in good shape!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer, and I’ll help you with it.”}},{“@type”: “Question”,”name”: “What Are The Primary Indicators Of Wear In A Lathe Carriage Rack Gear During Testing?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When testing a lathe carriage rack gear, you might notice some signs of wear. Look for missing teeth or grooves on the gear. You may also see uneven movement as the gear turns. Listen for strange sounds, like grinding or clanking, which can indicate problems. Finally, check for rough spots that can make it hard for the gear to turn smoothly.”}},{“@type”: “Question”,”name”: “How Can The Accuracy And Precision Of Lathe Operations Be Affected By The Wear Of Carriage Rack Gears?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When the carriage rack gears wear out, they do not fit together as well. This can cause the lathe, a tool that shapes metal or wood, to move less smoothly. If the lathe doesn’t move correctly, it can make mistakes, leading to parts that are not always the same size or shape. This means your work may be less accurate and precise, which is important for good results. Taking care of the gears helps keep your work looking great!”}},{“@type”: “Question”,”name”: “What Methods Are Commonly Used To Assess The Wear Characteristics Of Rack Gears In Lathe Carriages?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can check how much rack gears in lathe carriages wear out using a few methods. First, we look for signs of damage, like scratches or dents. Then, we might measure the gears to see if they still fit together well. We also listen for weird sounds when the lathe runs. Lastly, we can use a special tool to see how tightly the gears grip each other.”}},{“@type”: “Question”,”name”: “How Does The Material Composition Of A Rack Gear Influence Its Wear Resistance And Longevity In Lathe Applications?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The material of a rack gear is very important. If it’s strong and tough, it lasts longer. Good materials resist wear, which means they don’t break down easily. For lathe machines, this helps everything work smoothly. So, choosing the right material helps you keep using the gear without problems for a long time.”}},{“@type”: “Question”,”name”: “What Preventative Maintenance Practices Can Be Implemented To Reduce Wear On Lathe Carriage Rack Gears?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To help keep lathe carriage rack gears from wearing out, we can take some simple steps. First, always clean the gears regularly to remove dust and dirt. Next, we should oil the gears to keep them moving smoothly. We can also check for any loose parts and tighten them. Finally, use the lathe carefully to avoid putting too much pressure on the gears.”}}]}