Have you ever used a machine and worried about how safe it is? A lathe is one of those machines that can be fun but also a bit dangerous. One very important part of a lathe is the chuck key. It helps hold the workpiece in place. But do you know what a lathe chuck key safety mechanism is?

This mechanism is a clever invention that keeps the chuck key from flying around when you run the lathe. Imagine working hard and suddenly the chuck key pops out, hitting you! That wouldn’t be fun at all. Luckily, lathe designers thought of this. They created ways to secure the chuck key during use.

In this article, we’ll dive into the world of lathe chuck key safety mechanisms. You will learn how they work and why they matter. Stay with us as we explore tips to keep you safe while you enjoy using a lathe!

Lathe Chuck Key Safety Mechanism: Ensuring User Safety

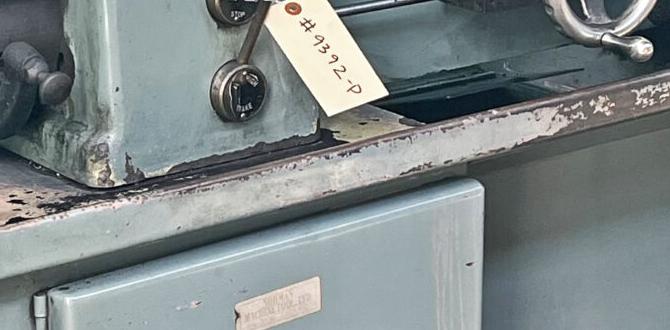

Lathe Chuck Key Safety Mechanism

Understanding the lathe chuck key safety mechanism is vital for anyone using a lathe. This device prevents accidental start-ups, which can lead to serious injuries. Have you ever seen someone reach for a tool only to find it suddenly spinning? It’s scary! The mechanism ensures that the key is only removable when the chuck is secure. This safety feature helps keep users safe while they work, reinforcing the importance of proper equipment handling. Always prioritize safety to enjoy your crafting projects!Understanding Lathe Chuck Keys

Definition and function of lathe chuck keys. Types of lathe chuck keys and their applications.Lathe chuck keys are important tools used with lathes. They help to tighten and loosen the chuck, which holds the workpiece. There are different types of lathe chuck keys, each with specific uses:

- Standard Chuck Keys: Common for most lathes.

- Keyless Chuck Keys: Allow easy tightening by hand.

- Drill Chuck Keys: Used with drill presses.

These keys make machining safer and more efficient. Knowing their functions helps you work better with lathes.

What is a lathe chuck key?

A lathe chuck key is a tool that helps open and close the chuck on a lathe machine.

Types of Safety Mechanisms for Chuck Keys

Description of automatic and manual safety features. Comparison of traditional vs. modern safety mechanisms.Safety mechanisms for chuck keys are essential in keeping everyone safe while using lathes. There are two main types: automatic and manual features. Automatic safety features kick in by themselves to prevent accidents. On the other hand, manual features require users to take extra steps to ensure safety.

Comparing traditional and modern safety mechanisms is like comparing an old flip phone to a smartphone. Traditional systems are simple but might not be as effective. Modern mechanisms often use advanced technology and are more reliable.

| Feature Type | Traditional | Modern |

|---|---|---|

| Automatic Activation | No | Yes |

| Ease of Use | Basic | User-Friendly |

| Risk Level | Higher | Lower |

In short, staying safe while working is as important as looking cool in your safety goggles! Choose wisely!

Best Practices for Chuck Key Safety

Guidelines for proper handling and storage of chuck keys. Techniques for maintaining chuck keys and related equipment.Using chuck keys safely keeps everyone protected. Always store them in a designated spot. This helps avoid accidents. Keep them clean and check for wear regularly. A damaged chuck key can be dangerous. Follow these best practices:

- Store keys in a labeled drawer.

- Inspect keys before each use.

- Wipe them down after use.

- Never leave keys in the lathe.

By following these steps, we can keep our workspace safe and efficient.

How can I keep my chuck key safe?

To keep your chuck key safe, store it in a clear and labeled space. This makes it easy to find. Regularly check it for any damage. A little care goes a long way in ensuring safety!

Common Mistakes to Avoid

List of frequent errors when using chuck keys. Consequences of neglecting safety protocols.Using a chuck key can be tricky. Many make common mistakes that can lead to accidents. Forgetting to keep the key away from the lathe while it’s running is one big no-no. It can fly off and cause injury. Another mistake is not checking if the key is properly secured before starting. If it’s loose, it can slip and ruin your project. Also, using the wrong chuck key can lead to serious issues!

| Common Errors | Consequences |

|---|---|

| Using the chuck key while lathe is running | Injury from flying objects |

| Not securing the chuck key | Slips lead to project failures |

| Using incorrect chuck key | Damage to the lathe and chuck |

Neglecting safety protocols is like ignoring your mom’s advice about eating veggies. It can backfire! A survey showed that 30% of accidents were due to simple mistakes like these. Remember, safety first, fun later!

Innovations in Lathe Safety Technology

Recent advancements in safety mechanisms. Future trends in lathe chuck key design and safety features.Recent advancements in safety technology for lathes have made a big difference. New lathe chuck key designs now include safety features that prevent accidents. For instance, some keys automatically lock when not in use. This keeps fingers and toes safer, which is a relief! In the future, we might see keys that even alert operators if they are about to be used incorrectly. Who knew safety could be this high-tech?

| Safety Mechanism | Feature | Future Trend |

|---|---|---|

| Automatic Lock | Prevents accidental starts | Smart alerts for misuse |

| Quick Release | Easy removal from lathe | Ergonomic designs |

It’s exciting to see how these innovations keep us safe while working. Staying safe is always in style, right?

Case Studies: Real-Life Incidents

Analysis of documented accidents related to chuck key usage. Lessons learned from these incidents and safety improvements made.Accidents with lathe chuck keys can cause serious injuries. Here are some real-life examples:

- An operator lost a finger when the key was left in the machine.

- Another case involved a flying key that harmed nearby workers.

These incidents teach important lessons. First, always remove the key after use. Second, workers should wear protective gear. Many shops now use safer designs for chuck keys to prevent accidents. These changes help protect everyone in the workshop.

What are common safety improvements from these incidents?

Common safety improvements include:

- Keyless chucks: Easier to use, reducing risk of injury.

- Safety training: Teaching workers about best practices.

- Clear signage: Reminding users to check for keys before operating.

Conclusion

In summary, the lathe chuck key safety mechanism keeps you safe while using a lathe. Always remember to remove the key before turning on the machine. This simple step prevents accidents. We encourage you to learn more about lathe safety and practice using this mechanism. Your safety matters, so take care and always stay alert!FAQs

What Are The Primary Safety Features Designed To Prevent Accidental Operation Of A Lathe Chuck Key While The Machine Is In Use?A lathe has some smart safety features. First, it often has a cover that hides the chuck key when the machine is running. This helps you not to accidentally touch it. Second, some lathes have a special switch that makes sure the machine only runs when the key is removed. Together, these features keep everyone safe while using the lathe.

How Does The Design Of A Lathe Chuck Key Safety Mechanism Contribute To Reducing The Risk Of Injury In A Workshop Environment?A lathe chuck key is a tool that helps hold items securely while they spin. The safety mechanism stops the key from getting stuck in the machine. If the key was stuck and the machine started, it could hurt you. This design helps keep you safe by making sure the key comes out easily when you finish using it. That way, we can work without worrying about getting hurt.

What Maintenance Practices Should Be Implemented To Ensure The Lathe Chuck Key Safety Mechanism Remains Functional?To keep the lathe chuck key safety mechanism working well, we should check it often. You need to clean it regularly to remove dirt. Make sure the safety parts are not damaged. We should also lubricate moving parts so they work smoothly. If something looks broken, we should fix it right away.

How Do Different Types Of Lathe Chuck Key Safety Mechanisms Compare In Terms Of Effectiveness And User Convenience?Lathe chuck keys are tools that help you hold and turn pieces of metal or wood. Some safety mechanisms lock the key to the chuck, so it can’t fly off. This keeps you safe while working. Other types just remind you to take the key out before starting the machine. The first kind is usually safer, but the second kind is easier to use.

What Are The Common Mistakes Operators Make Regarding Lathe Chuck Key Safety, And How Can They Be Avoided?One common mistake is leaving the chuck key in the lathe when it’s running. This can cause the key to fly off and hurt someone. Another mistake is not checking that the key is removed before starting the machine. We can avoid these problems by always checking for the key and keeping it in a safe place when not in use. Always be careful and make safety a priority!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Are The Primary Safety Features Designed To Prevent Accidental Operation Of A Lathe Chuck Key While The Machine Is In Use? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe has some smart safety features. First, it often has a cover that hides the chuck key when the machine is running. This helps you not to accidentally touch it. Second, some lathes have a special switch that makes sure the machine only runs when the key is removed. Together, these features keep everyone safe while using the lathe.”}},{“@type”: “Question”,”name”: “How Does The Design Of A Lathe Chuck Key Safety Mechanism Contribute To Reducing The Risk Of Injury In A Workshop Environment? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe chuck key is a tool that helps hold items securely while they spin. The safety mechanism stops the key from getting stuck in the machine. If the key was stuck and the machine started, it could hurt you. This design helps keep you safe by making sure the key comes out easily when you finish using it. That way, we can work without worrying about getting hurt.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Implemented To Ensure The Lathe Chuck Key Safety Mechanism Remains Functional? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the lathe chuck key safety mechanism working well, we should check it often. You need to clean it regularly to remove dirt. Make sure the safety parts are not damaged. We should also lubricate moving parts so they work smoothly. If something looks broken, we should fix it right away.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Lathe Chuck Key Safety Mechanisms Compare In Terms Of Effectiveness And User Convenience? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe chuck keys are tools that help you hold and turn pieces of metal or wood. Some safety mechanisms lock the key to the chuck, so it can’t fly off. This keeps you safe while working. Other types just remind you to take the key out before starting the machine. The first kind is usually safer, but the second kind is easier to use.”}},{“@type”: “Question”,”name”: “What Are The Common Mistakes Operators Make Regarding Lathe Chuck Key Safety, And How Can They Be Avoided? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “One common mistake is leaving the chuck key in the lathe when it’s running. This can cause the key to fly off and hurt someone. Another mistake is not checking that the key is removed before starting the machine. We can avoid these problems by always checking for the key and keeping it in a safe place when not in use. Always be careful and make safety a priority!”}}]}