Have you ever watched a lathe in action? It’s a fascinating process that can create beautiful shapes from metal. Many people love metalworking, but choosing the right tools is key. One important tool is a lathe collet system. This system holds pieces of metal tightly while they spin. When using the best metal lathe with a great collet system, you can achieve amazing results.

Imagine starting a project and knowing you have the best setup available. Wouldn’t that make your work easier and more enjoyable? A good collet system helps keep your metal secure, reducing mistakes. It’s like having a firm grip on a slippery object. Many beginners and experts agree on this.

Did you know that the right lathe collet system can save you time? That’s why choosing the best metal lathe is so important. You want tools that make your projects not just possible, but fun. So, let’s explore what makes a lathe collet system stand out and how it can change your metalworking game.

Lathe Collet System: The Best Metal Lathe Solutions

Discovering the Best Metal Lathe Collet System

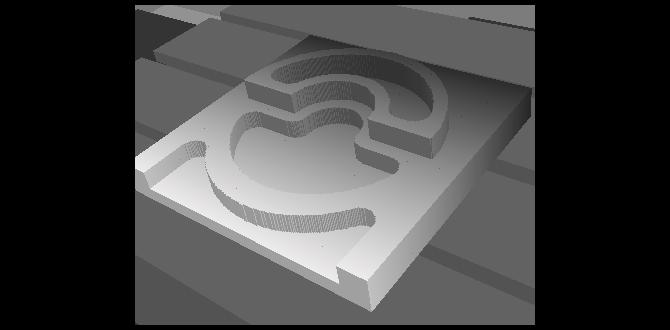

Imagine having a metal lathe that works seamlessly and holds your materials tightly. A lathe collet system is crucial for this. It offers better precision than standard chucks. Readers learn that the best systems can hold various sizes, making them versatile. This tool can help create intricate designs easily. Choosing the right collet system enhances efficiency and reduces setup time. So, are you ready to improve your metalworking projects? A good collet system could be your next best friend!What is a Lathe Collet System?

Definition and function of lathe collet systems. Key components and types of collet systems available.A lathe collet system grips workpieces tightly. It helps keep them steady while a lathe does its job. The main parts of this system include the collet, spindle, and nut. There are different types of collet systems like:

- 3-jaw collet: Holds round and hex shapes.

- 4-jaw collet: Allows for more precise clamping.

- Spinner collet: Quick change for different pieces.

This system is key for making parts accurately on a metal lathe. With the right collet setup, you improve your machining skills.

What is the purpose of a lathe collet system?

The purpose of a collet system is to secure the workpiece firmly during machining. It ensures precision and reduces errors, which leads to better results in metalworking.

Benefits of Using a Lathe Collet System

Enhanced precision and repeatability in machining. Increased versatility compared to traditional chuck systems.A lathe collet system offers many benefits for machining. It improves precision and repeatability, allowing parts to be made exactly the same way each time. This is great for big projects where accuracy matters. Collets also increase versatility when compared to traditional chucks. They can hold different shapes and sizes of materials, which makes switching tasks quicker and easier.

What are the advantages of using a lathe collet system?

The lathe collet system is very useful. It provides better accuracy in creating parts. This means less time fixing mistakes. Plus, it can hold various items securely, making it a more flexible option than regular chucks.

- High precision for consistent results

- Ability to work with diverse materials

- Faster job changes

- Less setup time

How to Choose the Best Lathe Collet System for Your Metal Lathe

Factors to consider (size, material, clamping force). Matching collet systems to specific metal lathe models.Choosing the right lathe collet system is like finding the perfect shoe size—it needs to fit just right! First, consider the size of the collet. It should match your metal lathe to hold your materials securely. Next, think about the material. A strong material ensures durability, so you don’t have to replace it every month—unless you’re looking to make your wallet lighter! Finally, check the clamping force to ensure the collet grips firmly without slipping. And remember, not all collets fit all lathes, so match them correctly. Here’s a quick lookup table for your reference:

| Lathe Model | Recommended Collet Size | Material Type |

|---|---|---|

| Model A | ER32 | Steel |

| Model B | ER40 | Aluminum |

| Model C | MT3 | Steel |

Remember, finding the right collet means your projects will turn out as smooth as your new favorite dance moves!

Top Recommendations for Lathe Collet Systems

Review of leading collet systems on the market. Detailed comparison of features, pricing, and user feedback.Many lathe collet systems stand out for their quality and value. A few top choices include:

- ER Collet System: Known for versatility, it offers a range of sizes. Users praise its strong grip.

- 5C Collet System: Affordable and straightforward. Many find it easy to use.

- DA Collet System: Features precision and reliability. Ideal for fine work.

Prices vary, so check reviews for feedback. Most users value performance and ease of use over cost. Choose a system that fits your needs best.

What is the best lathe collet system?

The best lathe collet system depends on your needs. The ER and 5C systems are top choices due to their flexibility and affordability. Always consider user feedback when selecting.

Installation and Maintenance of Lathe Collet Systems

Stepbystep installation guide. Best practices for maintenance to ensure longevity and performance.Installing a lathe collet system is simple. First, gather your tools like a wrench and cleaning cloth. Next, follow these steps:

- Secure the lathe in place.

- Attach the collet chuck to the spindle.

- Insert the collet into the chuck and tighten.

- Check alignment before use.

For maintenance, keep these tips in mind:

- Clean your collet after each use.

- Lubricate moving parts regularly.

- Inspect for wear or damage.

- Store in a dry place.

This way, your lathe collet system will last longer and work better. Proper care helps your tools stay in top shape!

How do I maintain my lathe collet system?

To maintain your lathe collet system, clean, lubricate, and inspect regularly. Keeping it in good shape will ensure it lasts a long time and performs well.

Common Issues and Troubleshooting with Lathe Collet Systems

Identification of frequent problems users encounter. Tips for resolving issues quickly and efficiently.Users of lathe collet systems often face some common issues. These can affect how well the machine works. Here are some frequent problems and quick fixes:

- Collet slipping during use.

- Difficulty when inserting or removing workpieces.

- Inaccurate cutting due to misalignment.

- Excessive vibration while operating.

To resolve these issues, check if the collet is clean and properly tightened. Adjust the alignment for better accuracy. Regular maintenance can also help keep your lathe running smoothly.

What are common issues with lathe collet systems?

Common issues include collet slippage, difficulty in handling workpieces, and misalignment leading to inaccurate cuts.

Future Trends in Lathe Collet Technologies

Innovations in collet design and materials. The impact of technology on precision machining and productivity.Many exciting changes are happening in collet technology. New designs are making collets lighter and stronger. Advanced materials help them last longer. This means less time fixing tools and more time making things. Technology is also improving precision machining. It makes machines work faster and better. This rise in efficiency boosts productivity in workshops everywhere.

What are the latest trends in collet technologies?

The latest trends focus on better materials and smarter designs. 3D printing opens doors for unique shapes and sizes. Manufacturers use high-performance alloys for durability. This helps achieve tighter tolerances and smoother finishes.

Key Innovations:

- Lightweight materials for easy handling

- Advanced designs for maximum grip

- Smart technology for real-time adjustments

These innovations promise to improve the lathe collet system best metal lathe experience for everyone. They make machining safer, quicker, and more precise.

Conclusion

In summary, a lathe collet system is crucial for using the best metal lathe. It holds workpieces tightly, improving precision and quality. Choosing the right collet enhances your work experience. Now that you know its benefits, consider exploring different options and brands. Dive deeper into lathe systems to find what suits you best for your projects. Happy turning!FAQs

Sure! Here Are Five Questions Related To The Lathe Collet System And The Best Metal Lathes:Sure! Here are five simple answers to questions about lathes. A lathe is a machine that spins metal to shape it. A collet is a tool that holds the metal tightly while you work. You want a good lathe because it helps you make better projects. Some popular lathes are small and easy to use, which makes them great for beginners!

Sure! Please ask your question, and I’ll be happy to help.

What Advantages Does A Collet System Offer Over Traditional Chuck Systems In Metal Lathes?A collet system grips the metal part more tightly than a traditional chuck. This helps make cleaner cuts and smoother pieces. You can change the size of the collet easily for different parts. Also, collets give you better accuracy, which means your work looks nicer. Overall, they can help you work faster and more efficiently.

What Are The Key Features To Look For When Selecting A Metal Lathe With A Collet System?When picking a metal lathe with a collet system, you should check a few important things. First, look for the size of the collet so it fits your projects. Next, consider how easy it is to change the collets. You want it to be simple! Also, think about the lathe’s power. A stronger motor helps with tough jobs. Finally, check the lathe’s build quality for long-lasting use.

How Do Different Types Of Collets (E.G., Er, Tg, And 5C) Compare In Terms Of Versatility And Precision For Metalworking?Collets are special tools that hold things tightly in machines. ER collets are very versatile, meaning they can hold many sizes of tools. TG collets are great for really precise work, making sure everything fits perfectly. 5C collets are also precise, but not as flexible as ER. So, if you want to use many tools, go for ER; if you need exactness, TG or 5C are better.

Which Brands Or Models Are Considered The Best Metal Lathes Equipped With A Collet System For Hobbyists And Professionals Alike?Some great metal lathes with a collet system for hobbyists and professionals include the Sherline 4410 and the Grizzly G0602. They are popular because they are easy to use and make precise parts. The Taig Micro Lathe is also a good choice for small projects. If you want something bigger, check out the Jet JWL-1442VS. These lathes help you create cool stuff easily!

How Can You Properly Set Up And Maintain A Collet System In A Metal Lathe For Optimal Performance?To set up a collet system on a metal lathe, first choose the right size collet for your workpiece. Next, clean the collet and the spindle to remove any dirt. Then, carefully insert the workpiece into the collet and tighten it securely. Make sure everything is aligned properly to avoid problems. To maintain it, always clean it after use and check for any damage regularly. This way, your collet system will work great!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Lathe Collet System And The Best Metal Lathes:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five simple answers to questions about lathes. A lathe is a machine that spins metal to shape it. A collet is a tool that holds the metal tightly while you work. You want a good lathe because it helps you make better projects. Some popular lathes are small and easy to use, which makes them great for beginners!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please ask your question, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Advantages Does A Collet System Offer Over Traditional Chuck Systems In Metal Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system grips the metal part more tightly than a traditional chuck. This helps make cleaner cuts and smoother pieces. You can change the size of the collet easily for different parts. Also, collets give you better accuracy, which means your work looks nicer. Overall, they can help you work faster and more efficiently.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For When Selecting A Metal Lathe With A Collet System?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When picking a metal lathe with a collet system, you should check a few important things. First, look for the size of the collet so it fits your projects. Next, consider how easy it is to change the collets. You want it to be simple! Also, think about the lathe’s power. A stronger motor helps with tough jobs. Finally, check the lathe’s build quality for long-lasting use.”}},{“@type”: “Question”,”name”: “How Do Different Types Of Collets (E.G., Er, Tg, And 5C) Compare In Terms Of Versatility And Precision For Metalworking?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Collets are special tools that hold things tightly in machines. ER collets are very versatile, meaning they can hold many sizes of tools. TG collets are great for really precise work, making sure everything fits perfectly. 5C collets are also precise, but not as flexible as ER. So, if you want to use many tools, go for ER; if you need exactness, TG or 5C are better. “}},{“@type”: “Question”,”name”: “Which Brands Or Models Are Considered The Best Metal Lathes Equipped With A Collet System For Hobbyists And Professionals Alike?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Some great metal lathes with a collet system for hobbyists and professionals include the Sherline 4410 and the Grizzly G0602. They are popular because they are easy to use and make precise parts. The Taig Micro Lathe is also a good choice for small projects. If you want something bigger, check out the Jet JWL-1442VS. These lathes help you create cool stuff easily!”}},{“@type”: “Question”,”name”: “How Can You Properly Set Up And Maintain A Collet System In A Metal Lathe For Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a collet system on a metal lathe, first choose the right size collet for your workpiece. Next, clean the collet and the spindle to remove any dirt. Then, carefully insert the workpiece into the collet and tighten it securely. Make sure everything is aligned properly to avoid problems. To maintain it, always clean it after use and check for any damage regularly. This way, your collet system will work great!”}}]}