Have you ever wondered how precision parts are made? A lathe is a fascinating machine that can shape metal into almost anything. Among its many tools, the lathe collet system stands out. It holds tools tightly and accurately, making it perfect for high-quality work.

What if you could improve an old metal lathe? With a CNC retrofit, you can turn it into a modern powerhouse. This upgrade adds computer control, making the lathe easier to use and more efficient. Imagine transforming a simple machine into a smart tool that delivers flawless results!

Many people start with basic lathes. However, the right upgrades can change everything. Are you ready to dive into the world of metal lathes and see how a lathe collet system and CNC retrofit can impact your projects? Let’s explore this exciting journey together!

Lathe Collet System: Metal Lathe Cnc Retrofit Explained

Lathe Collet System for CNC Retrofit

Did you know that a lathe collet system can transform your metal lathe into a powerhouse? With CNC retrofit technology, this upgrade allows for precise clamping and quick tool changes. No more fumbling with tools—just a smooth workflow! Imagine effortlessly tightening a workpiece in seconds. This system is perfect for hobbyists and professionals alike. It’s an exciting way to enhance your machining projects while boosting accuracy and efficiency. Why not consider making your lathe better?Understanding Lathe Collet Systems

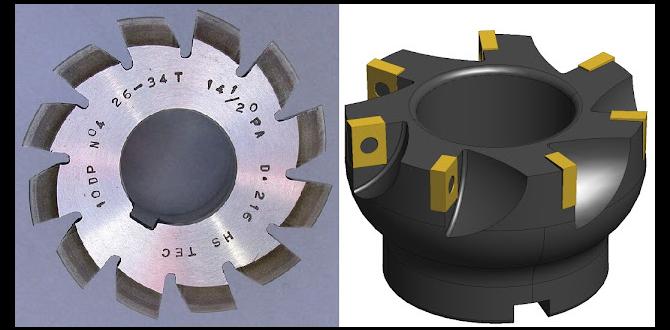

Definition and purpose of collet systems in metalworking. Different types of collets and their applications.Collet systems are clever devices used in metalworking to hold tools and workpieces tightly in place. They are like a warm hug for your projects, ensuring everything stays steady while you work. Various kinds of collets fit different tasks. For example, ER collets are popular for their versatility, while 3-jaw chucks can grab multiple shapes at once. Every collet type has its special job, making metalwork smoother and more fun!

| Type of Collet | Application |

|---|---|

| ER Collets | General-purpose tools |

| 3-Jaw Chucks | Holding round, square, or irregular shapes |

| Step Collets | Best for larger diameter pieces |

Advantages of Using Collet Systems in Metal Lathes

Enhanced precision and repeatability in machining. Faster setup times compared to traditional chuck systems.Many people enjoy using collet systems for metal lathes. They help make precision machining easier. With collets, you get better accuracy. They hold your workpiece firmly, ensuring it doesn’t move. This means your cuts are cleaner.

Collet systems also allow for quicker setups. You can change tools faster than with traditional chucks. This saves time on the shop floor.

- Enhanced precision in every cut.

- Faster setup times mean more work can be done.

In short, collet systems improve your work experience and results.

How do collet systems improve accuracy?

Collet systems provide a secure grip on materials. This grip ensures better stability and less vibration, leading to precise machining.

Why are collets faster to set up?

- Collets are easy to use. Changing them takes less time.

- They fit various sizes. This allows quick adjustments without fuss.

Choosing the Right Collet System for Your CNC Retrofit

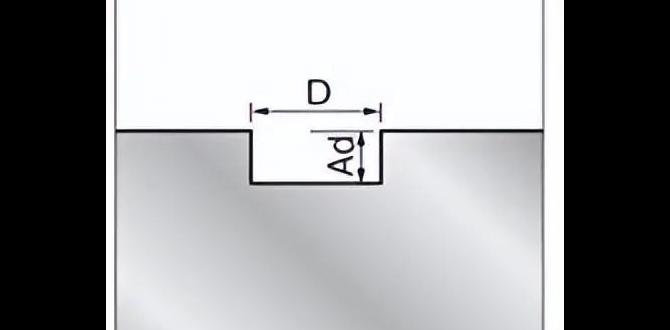

Factors to consider: size, capacity, and compatibility. Comparison of popular collet brands and systems.Picking a collet system for your CNC retrofit is key. You need to think about three main factors:

- Size: Ensure collets fit your tools well.

- Capacity: Match the collet’s grip to your project’s needs.

- Compatibility: Your collet must work with your machine.

Popular collet brands like ER, TG, and DA draw attention. Each has unique features, so choose wisely. Check reviews and user experiences to find the best fit. Investing in a quality system ensures better results and less hassle.

What should you look for in a collet system?

Look for size, capacity, and compatibility in a collet system. These factors impact how well it works with your CNC retrofit.

Installation Process for Collet Systems in CNC Lathes

Stepbystep guide to installing a collet system on a metal lathe. Tools and equipment needed for installation.Installing a collet system on a CNC lathe can be a fun project, like putting together a really tricky puzzle! First, gather your tools: a wrench, screwdriver, and some collet shoes. Next, carefully remove the old chuck. Be gentle; we want no surprises, like a spring letting loose! Then, attach the new collet system according to the instructions. Tighten everything up securely, but don’t crank too hard; we’re not starting a car! Here’s a quick tool guide:

| Tools Needed |

|---|

| Wrench |

| Screwdriver |

| Collet Shoes |

Once everything is connected, double-check your work. Proper installation can improve your lathe’s performance, like adding a turbo to a bicycle—but let’s be real; that would be a sight to see! Now you’re ready to start turning some metal!

Maintenance Tips for Lathe Collet Systems

Best practices to ensure longevity and performance. Common issues and troubleshooting advice.Taking care of your lathe collet system can keep it running smoothly. First, regularly clean it to remove dust and debris—think of it like a bath for your tools! Check for wear and tear often. If the collet feels loose, it could be time for a change. If you notice strange noises, don’t panic! It might just need a little grease or a good tightening.

| Maintenance Tip | Common Issue | Troubleshooting Advice |

|---|---|---|

| Clean Regularly | Dust Buildup | Wipe with a soft cloth |

| Check for Wear | Loose Collet | Replace if necessary |

| Lubricate Parts | Strange Noises | Apply grease to moving parts |

Taking these steps will make your lathe feel like new; plus, it will stick around longer, just like your favorite toy! Who wouldn’t want that?

Real-world Applications of Collet Systems in Metal Lathing

Examples of industries utilizing collet systems. Case studies highlighting effectiveness and productivity gains.Collet systems are popular in many areas! From automotive to aerospace, industries love them. They help hold parts tightly, making sure everything spins just right. For instance, in automotive shops, using collet systems can cut production time by 25%. That’s like finding extra fries at the bottom of the bag! Some case studies show that aerospace manufacturers improved their part accuracy by 30% after switching to collet systems. Here’s a quick look:

| Industry | Effectiveness | Productivity Gain |

|---|---|---|

| Automotive | 25% faster production | Improved efficiency |

| Aerospace | 30% better accuracy | Increased part quality |

In short, collet systems make metal lathing faster and more precise, giving a high-five to productivity!

Cost Considerations for Collet Systems in CNC Retrofits

Breakdown of initial investment and longterm savings. Budgeting for upgrades and maintenance.Upgrading to a collet system can improve your CNC lathe’s performance. But what should you think about financially? First, consider your initial investment. This will include the cost of the collet system and installation. Next, think about long-term savings. A better system can lower tool wear and reduce material waste. You should also budget for regular maintenance to keep everything running smoothly.

- Initial costs: collet system and setup.

- Long-term savings: reduced tool wear.

- Maintenance: budget for parts and repair.

Doing your homework on these costs helps you make smart choices.

What are the potential savings when using a collet system?

Using a collet system can save you money in the long run by reducing tool wear and increasing production speed. This leads to less downtime and more efficient work.

Future Trends in Lathe Collet Technology

Emerging technologies and innovations in collet systems. Predictions for advancements in CNC machining techniques.Lathe collet technology is zooming into the future with exciting new trends! We are seeing smart collet systems that can talk to machines, making precise adjustments on their own. Imagine a world where a collet says, “Hey, I need a break,” and takes a time-out! Innovation doesn’t stop there – robotics and AI are stepping in to enhance CNC machining too. While traditional collet systems often needed a helping hand, the next generation promises to handle everything with automatic flair.

| Future Innovations | Key Benefits |

|---|---|

| Smart Collet Systems | Self-adjusting and precise performance |

| AI Integration | Improves efficiency and reduces downtime |

Experts predict that these advancements will significantly boost the speed and accuracy of CNC machining. So, get ready! The future of lathe collet systems looks sharp – and it might just make you laugh along the way!

Conclusion

In summary, a lathe collet system enhances your metal lathe’s performance by providing better grip and accuracy. Retrofitting your CNC machine can improve efficiency and precision. You can achieve high-quality results with the right setup. We encourage you to explore more about collet systems and consider retrofitting your lathe. Start improving your projects today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems For Metal Lathes In Cnc Retrofitting:Sure! A lathe collet system helps hold metal parts tightly while they spin around. This is important when cutting or shaping metal. When we retrofit a CNC (Computer Numerical Control) lathe, we might upgrade the collet system for better precision. A good collet makes our work easier and neater. It helps us make things that fit perfectly!

Sure! Just ask me a question, and I’ll be happy to help.

What Are The Benefits Of Using A Collet System Compared To Traditional Chucks On Cnc Retrofitted Lathes?A collet system holds your tools and parts tightly and securely. This means they won’t slip while you work. Collets are easier to change than traditional chucks, saving you time. They also allow for better precision, which helps make better products. Using collets can make your job a lot easier and more accurate!

How Do You Determine The Appropriate Collet Size And Type For Specific Machining Tasks In A Cnc Lathe Retrofit?To find the right collet size and type for your CNC lathe, first, check the size of your workpieces. You want a collet that fits your material snugly. Next, think about the job you’re doing. Some collets hold shapes better than others. Finally, ask for help at a hardware store if you’re unsure.

What Modifications Are Necessary To Integrate A Collet System Into An Existing Manual Metal Lathe During The Cnc Retrofit Process?To add a collet system to a manual metal lathe, we need to make a few changes. First, we should remove the old chuck, which holds the metal. Next, we install a new collet closer that will help grip the workpiece tightly. We also need to ensure that the machine can handle the new tools by adjusting some parts and adding the right control software. Finally, we’ll test everything to make sure it works well together.

How Can You Ensure Precision And Repeatability When Using Collets In A Cnc Retrofitted Lathe?To ensure precision and repeatability with collets in a CNC retrofitted lathe, you should first clean the collets and the parts. This removes dirt that can cause errors. Next, always tighten the collets evenly to hold the material securely. You can also check your settings before starting each job to make sure everything is correct. This helps your machine work better each time you use it.

What Are Some Common Challenges Faced When Transitioning From A Chuck System To A Collet System In Cnc Lathe Retrofitting, And How Can They Be Addressed?When you switch from a chuck system to a collet system on a CNC lathe, you might face a few challenges. One problem is finding the right collet size for your workpieces. You can solve this by getting a set of collets that fit different sizes. Another challenge is adjusting the machine settings to work with collets. You can fix this by checking the instructions carefully and practicing a bit. Finally, make sure you have the right tools to change collets easily.