Have you ever wondered how metal parts are shaped with such precision? The magic often lies in the lathe collet system. This system holds the metal securely while the lathe spins it. But what does this mean for you? Imagine creating your own metal designs!

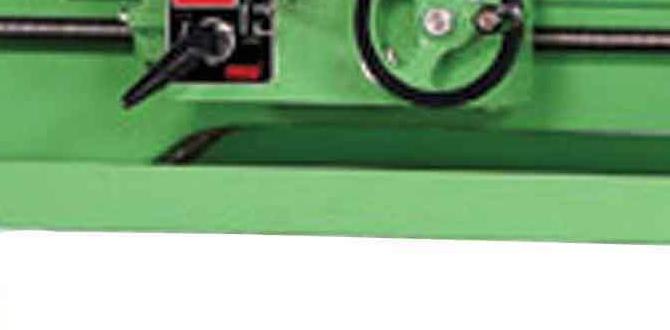

Using a metal lathe can seem tricky, but it doesn’t have to be. With a simple control panel, anyone can start machining. Just think about it: with the right tools, you could make unique items, from furniture to art pieces.

Did you know that a lathe can be an artist’s best friend? People across the world use these machines to turn their ideas into reality. The combination of a solid collet system and a friendly control panel makes it easier than ever!

Join us as we explore the world of metal lathes. Let’s dive into how the lathe collet system works and how the control panel makes all the difference. You’ll be amazed by what you can create!

Lathe Collet System: Optimizing Your Metal Lathe Control Panel

Understanding the Lathe Collet System and Control Panel

The lathe collet system is a handy tool for holding workpieces securely while they spin. This system comes with different collet sizes, allowing for easy swapping of tools. Have you ever had trouble keeping your workpiece steady? A reliable collet can solve that issue! Controlling a metal lathe involves understanding the control panel. It’s where you adjust speed and settings. Knowing how to use it can dramatically improve your results. Overall, mastering these tools makes metalworking easier and more enjoyable.What is a Lathe Collet System?

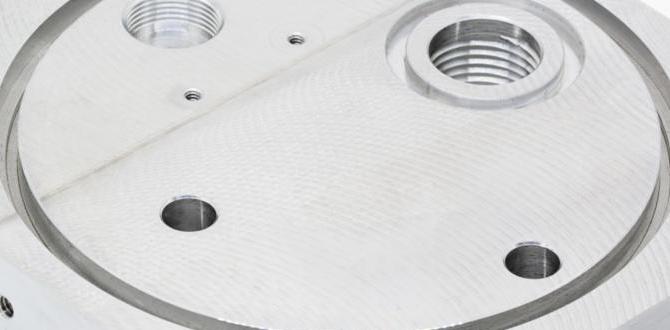

Definition and purpose of lathe collets. Types of collets used in lathe systems.A lathe collet system is a tool that helps hold round objects tightly on a lathe. It grips workpieces securely, allowing for smoother and more precise cuts. Collets are small parts that can expand or contract to fit different sizes. Their main purpose is to keep materials steady during machining.

There are several types of collets used:

- Elastic Collets: Flexible and can hold various sizes.

- Step Collets: Provide multiple gripping points.

- Hex Collets: Secure hex-shaped objects tightly.

What are the main purposes of lathe collets?

The main purposes of lathe collets are to securely hold workpieces and allow precise machining. They ensure that materials do not move, resulting in better quality work.

Advantages of Using a Collet System in Metal Lathes

Increased precision and accuracy in machining. Quick changeover and setup times.Using a collet system in metal lathes brings many benefits. First, it improves precision and accuracy in machining work. This means parts fit better and work properly. Second, changing tools is quick and easy. This leads to faster setup times.

- Better clamping holds workpieces tightly.

- Less setup time boosts productivity.

Many machinists love collets for these reasons. They help make great products efficiently.

What are the main benefits of using a collet system?

Collet systems allow for precise machining and fast tool changes. This saves time and ensures accuracy, making your work easier and quicker.

How to Choose the Right Collet for Your Project

Factors to consider: size, type, and material compatibility. Common applications for various collet types.Choosing the right collet is important for your project. Consider these factors:

- Size: Ensure the collet fits your workpiece tightly.

- Type: Different collets work better for different jobs.

- Material Compatibility: Make sure it’s suitable for your material.

Common applications include:

- Cylindrical collets: Ideal for round objects.

- Hex collets: Great for hexagonal shapes.

- Square collets: Used for square materials.

What key factors should I think about?

Think about size, type, and material when selecting a collet for your tasks. It’s essential to pick what works best for your project for good results.

Programming and Operating the Control Panel

Basic programming concepts for lathe control panels. Stepbystep guide for setting up a machining job.Understanding your control panel is like finding the cheat code to video games! First, you’ll want to grasp basic programming concepts. Think of it as speaking the machine’s language. Start with simple commands and settings.

Next, here’s a quick guide to set up your machining job:

| Step | Description |

|---|---|

| 1 | Turn on the lathe and check the display. |

| 2 | Select your material type using buttons. |

| 3 | Input your desired measurements carefully. |

| 4 | Start the machine and watch it work! |

Remember, practice makes perfect! And don’t worry if you press the wrong button. Just pretend you were testing the “dance feature”! Happy machining!

Maintenance Tips for Collet Systems and Control Panels

Regular maintenance practices for longevity and performance. Troubleshooting common issues with collet systems and control panels.Taking care of your collet system and control panel is key to keeping them working well. Regular checks help prevent problems. Here are some tips:

- Clean dust and chips regularly.

- Check for signs of wear or damage.

- Lubricate moving parts to ensure smooth operation.

If you notice issues, try these solutions:

- For a stuck collet, gently tap it to release.

- Check connections if the control panel isn’t responding.

Taking these steps can improve performance and extend the parts’ life.

How can I troubleshoot common collet issues?

To troubleshoot common collet issues, ensure it is clean, check for damage, and confirm it’s tightly fitted. Regular checks can solve many problems before they start!

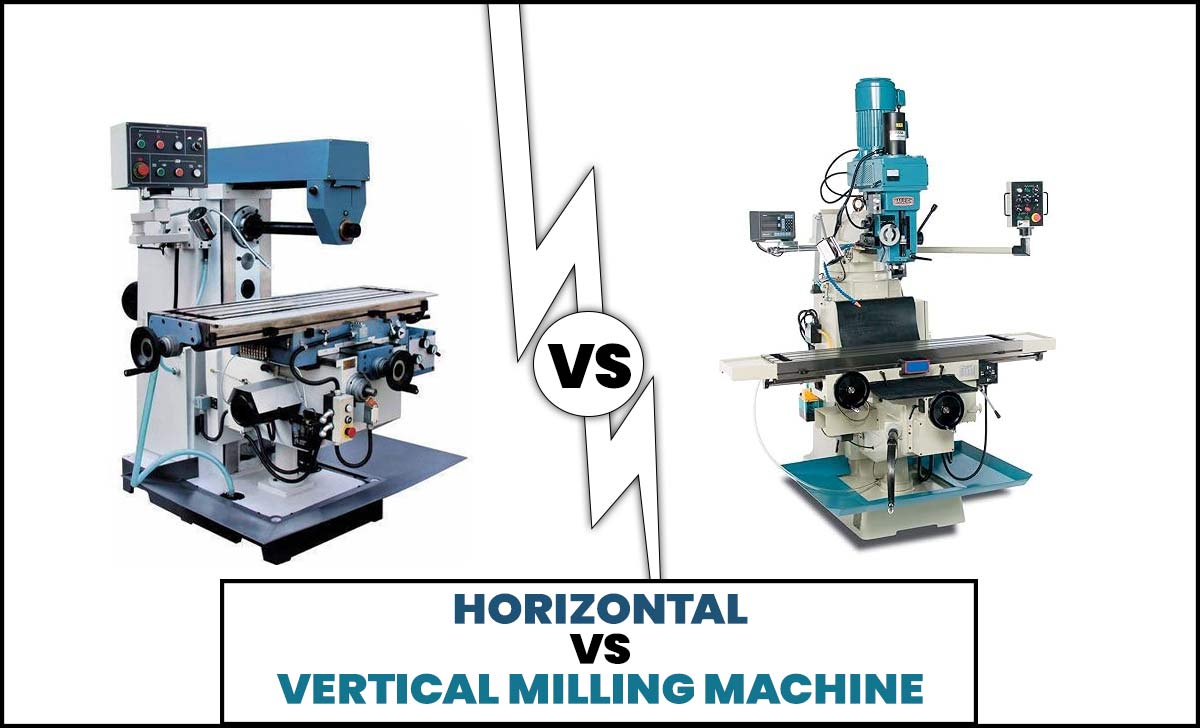

Comparing Manual vs. CNC Metal Lathe Control Panels

Differences in operation and functionality. Pros and cons of each type in various applications.Manual and CNC metal lathes are quite different in how they work. A manual lathe needs a person to control it carefully. Operators turn knobs and move parts by hand. In contrast, CNC lathes follow computer instructions, making them faster and more precise. Here are some key differences:

- Operation: Manual lathes require more hands-on effort, while CNC lathes are automated.

- Functionality: CNC lathes perform complex tasks easily, but manual lathes offer total control.

- Pros of Manual: Lower cost, quick adjustments.

- Cons of Manual: More skill needed, often slower.

- Pros of CNC: High precision, less operator fatigue.

- Cons of CNC: Higher initial cost, requires programming skills.

Choosing between the two depends on the project needs. Do you need speed and precision? Go CNC. Want to keep it simple? A manual lathe works fine!

What is the main difference between manual and CNC lathes?

The main difference is that manual lathes rely on human control, while CNC lathes use computers for operation. This affects precision and speed greatly.

What are the pros and cons of each?

Manual lathes are cheaper and allow for quick changes but need skilled operators. CNC lathes offer high accuracy and are user-friendly but come with a higher cost.

Future Trends in Lathe Technologies

Innovations in collet systems and control panel designs. Potential impact of automation and smart technology on lathe operations.New ideas in the lathe world are exciting! Collet systems are becoming easier to use, making work faster and smoother. Control panels are being redesigned for better visibility and more features. Automation is changing everything. Machines can now do tasks with less help from people. This not only saves time but also boosts precision. Smart technology is the future. It helps machines work together, making production quicker and smarter. Ready for this change?

What are the benefits of smart technology in lathe operations?

Smart technology improves accuracy, reduces errors, and speeds up production in lathe operations.Key Benefits:

- Increased efficiency

- Less waste

- Enhanced safety

Conclusion

In summary, the lathe collet system holds workpieces securely for precise cutting. The metal lathe control panel lets you adjust settings easily. Understanding these tools helps you improve your projects. We encourage you to explore more about lathe operations. Try hands-on practice to build your skills. Let’s keep learning and making amazing things together!FAQs

Certainly! Here Are Five Questions Related To The Lathe Collet System And The Metal Lathe Control Panel:Sure! The lathe collet system holds the metal piece tightly while we work on it. It helps us make the metal smooth and shaped just right. The metal lathe control panel has buttons and knobs we turn to make the machine work. You use it to change speeds or start and stop the lathe. This way, we can create cool shapes from metal safely and easily!

Sure! Please let me know what question you would like me to answer.

What Are The Advantages Of Using A Collet System Over A Three-Jaw Chuck In A Metal Lathe?Using a collet system is better than a three-jaw chuck for some reasons. First, collets hold the metal more tightly. This means your workpiece won’t slip. Second, collets fit more different shapes and sizes. They help us make more accurate pieces. Finally, changing collets is faster and easier. This saves you time!

How Do You Properly Set Up A Collet System On A Metal Lathe For Optimal Precision And Performance?To set up a collet system on a metal lathe, start by cleaning the collet and the chuck. Next, choose the right size collet for your workpiece. Slide the collet into the chuck and tighten it securely. Make sure the workpiece is straight and sits properly in the collet. Finally, check everything for tightness before you begin using the lathe.

What Are The Key Features To Look For In A Control Panel For A Metal Lathe Equipped With A Collet System?When choosing a control panel for a metal lathe with a collet system, look for clear buttons. Easy-to-read labels help us understand the settings. A digital display shows speed and settings, making work easier. Safety features are important to protect us while we use the lathe. Finally, adjustable controls let you change settings based on the job.

How Can A Lathe Operator Troubleshoot Common Issues That Arise With Collet Gripping Or Collet Alignment?If you’re a lathe operator and your collet isn’t gripping well, first check if it’s clean. Dirt or chips can stop it from working right. Next, look to see if the collet is aligned properly. You can adjust it to make sure it fits snug. Lastly, if it’s still not working, try using a different size collet that matches your piece better.

What Safety Precautions Should Be Taken When Operating A Metal Lathe With A Collet System To Prevent Accidents And Injuries?When using a metal lathe with a collet system, always wear safety goggles to protect your eyes. Keep your hair tied back and wear tight-fitting clothes. Never reach into the machine while it’s running. Make sure to have your hands clear of the moving parts. Finally, read the manual and follow all safety instructions carefully.