Have you ever struggled to hold work pieces firmly while using a metal lathe? Then you might appreciate the importance of a lathe collet system. This system can make your projects smoother and more efficient.

Imagine working on a cool metal project. You have a vision, but your tools aren’t cooperating. Frustrating, isn’t it? A lathe collet system can change that. It secures your materials tightly, so you can focus on creating.

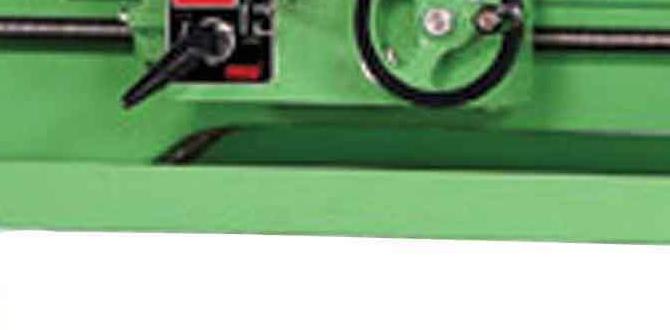

The cross slide on a metal lathe is another essential part. It helps you move your cutting tool side to side with precision. When connected with the right collet system, you can achieve impressive results.

Did you know that using the right setup can save you time and materials? Many hobbyists and professionals swear by it. So, let’s dive deeper into how a lathe collet system and the cross slide can boost your metalworking skills!

Lathe Collet System: Enhancing Metal Lathe Cross Slide Performance

Understanding the Lathe Collet System for Metal Lathes

The lathe collet system plays a crucial role in metal lathes. It holds the workpiece firmly while allowing precise machining. This system makes it easy to change tools quickly, saving time and effort. Did you know that using a good collet can improve accuracy? The cross slide feature also allows you to move the workpiece smoothly and control the cutting tool’s position better. Together, they enhance efficiency and quality in metalworking projects.What is a Lathe Collet System?

Definition and purpose of a lathe collet system. Types of collets commonly used in metal lathes.A lathe collet system is a tool that helps hold different pieces of metal tightly while they are cut or shaped. It uses special clamps called collets to grip the metal. This makes sure the metal stays still for precise work.

Common types of collets are:

- **Hex Collets**: For holding hex-shaped items.

- **Round Collets**: For round shapes, giving a good grip.

- **Square Collets**: Perfect for square items, ensuring stability.

This system is important for better accuracy in metal lathes. It allows for smooth and quick changes of pieces without losing tightness.

What is the purpose of a lathe collet system?

The primary purpose of a lathe collet system is to hold materials securely while they are being worked on. Strong grips lead to better, safe results.

What types of collets are commonly used?

Collets come in various shapes. Round collets and hex collets are the most popular. Each one serves a special need in metalwork.

Benefits of Using a Collet System in Metal Lathes

Enhanced precision and repeatability in workpieces. Advantages in setups for different materials and shapes.Using a collet system in metal lathes offers many benefits. It greatly improves precision and repeatability for workpieces. This means parts fit better and work well over and over. A collet system also makes it easier to set up for different materials and shapes. Here are some key advantages:

- Quick and easy changes between jobs.

- Holds various shapes tightly and securely.

- Minimizes errors during production.

This is why many machinists prefer using collets over other methods!

What are the main benefits of a collet system?

The main benefits include better accuracy and quick setups. This helps machinists save time and produce high-quality work.

How to Choose the Right Collet for Your Metal Lathe

Factors to consider: size, type, and application. Popular collet types for various machining tasks.Choosing a collet for your metal lathe can feel like picking your favorite ice cream flavor. You have many options! First, check the size. It should match your lathe’s specifications. Next, think about the type; common varieties include ER, collet chuck, and 5C collets. Each type has its own charm, like a superhero with different powers! Finally, consider the application. Will you be carving wood or shaping metal? Your task will guide your choice. Here’s a quick table to help you out:

| Collet Type | Best For |

|---|---|

| ER Collet | General machining |

| 5C Collet | Precision work |

| Collet Chuck | Heavy-duty tasks |

Remember, choosing the right collet will make your machining tasks smoother than a buttered biscuit!

Setting Up the Collet System on a Metal Lathe

Stepbystep guide to installing and aligning a collet. Common pitfalls and how to avoid them during setup.To install a collet on your metal lathe, start by removing the old chuck. Next, place the collet into the spindle, making sure it fits snugly. Tighten it gently, but don’t go all Hulk on it! Use an alignment tool to check if it’s straight. Common mistakes include not cleaning the spindle and using the wrong size collet. Avoid these and everything should spin smoothly! Below is a quick setup guide:

| Step | Action |

|---|---|

| 1 | Remove the old chuck. |

| 2 | Insert the collet into the spindle. |

| 3 | Tighten it. |

| 4 | Check alignment. |

Remember, comedy is key, so if something goes wrong, just laugh it off. You’re learning!

Maintaining Your Lathe Collet System

Best practices for cleaning and lubricating collets. Signs of wear and how to replace damaged components.Keeping your collet system in good shape is key. Start by cleaning collets often. Use a soft cloth to remove dirt. For lubrication, use light oil to keep parts moving smoothly. Check for signs of wear like cracks or chips. If you find any, replace those parts immediately. This will help your machine run better.

How often should I clean my lathe collet system?

Clean your lathe collet system every time you use it or at least once a month. Regular cleaning keeps it in top shape!

- Wipe the collets with a soft cloth.

- Apply light oil to moving parts.

- Check for cracks or damage.

Applications of the Collet System in Metal Turning

Common uses in different industries (automotive, aerospace, etc.). Examples of intricate projects that benefit from collet systems.The collet system has many uses in different industries. In the automotive sector, it helps create precise parts like engine components. In aerospace, collets make intricate fixtures for planes and rockets.

Some detailed projects that benefit from collet systems include:

- Manufacturing custom tools

- Creating small medical devices

- Forming detailed jewelry pieces

These systems provide strong grip and accuracy, making them vital for high-precision work. With their help, many industries can produce top-quality products safely and efficiently.

Why use collets in metal turning?

Collets provide strong holding power and accuracy, making machining easier. They reduce the chances of part damage and improve overall productivity.

Comparing Collet Systems to Other Workholding Methods

Advantages and disadvantages compared to chucks and vises. Situations where collets are preferred over alternatives.Collet systems hold workpieces tight and steady. They have some advantages over chucks and vises. For example, they provide better accuracy and quick changes when moving from part to part. However, they can be more expensive. Chucks and vises might be easier to find and use for some tasks but may not grip as well. Use collets if you need precision and speed.

What are the pros and cons of using collets?

Advantages:

- Better grip on small parts.

- Fast tool changes.

- High accuracy in cutting.

Disadvantages:

- More costly than other methods.

- Limited to specific sizes.

- Can be tricky for beginners.

Future Trends in Lathe Collet Systems

Innovations and advancements in collet technology. The impact of automation and smart technology on collet systems.Future innovations in collet technology are about to take us into a fun new world. Imagine collets that adapt like chameleons! New materials make them stronger and lighter. Plus, automation is joining the party, making adjustments smoother than your favorite dance moves. Smart technology is like your robot sidekick, helping to prevent errors and save time. Isn’t it time for lathe work to become a bit more high-tech?

| Innovation Type | Impact |

|---|---|

| Advanced Materials | Stronger and lighter collets |

| Automation | Smoother adjustments |

| Smart Technology | Reduces errors, saves time |

With these advancements, the future looks bright and exciting for lathe collet systems. More efficiency means more time for creativity! So, get ready to say goodbye to boring lathes and hello to a fun, tech-savvy workshop!

Conclusion

In conclusion, a lathe collet system is essential for precision machining on a metal lathe. It holds workpieces firmly, helping you achieve accurate cuts. The cross slide allows smooth movement for detailed adjustments. To get started, explore basic lathe operation guides. Practicing these skills will make you more confident in using a lathe effectively. Happy machining!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Cross Slides:Sure! Here are five questions you might ask about lathe collet systems and metal lathe cross slides: 1. What is a collet system? A collet system helps hold things tightly in place on a lathe. It keeps items steady while you work. 2. How does a lathe cross slide work? The cross slide is a part that moves side to side. It helps position the tool where you need it on the workpiece. 3. Why do we use collets instead of a chuck? Collets hold the material more securely than a regular chuck. They can also be faster to change. 4. Can I use different size collets? Yes! You can use different collets for different sizes of materials. Just change the collet to match what you’re using. 5. How do I care for my cross slide? Keep it clean and oiled. This helps it move smoothly and last longer.

Sure! Please provide the question you would like me to answer.

What Are The Advantages Of Using A Collet System Compared To A Standard Three-Jaw Chuck On A Metal Lathe?Using a collet system is better for some jobs than a three-jaw chuck. Collets hold the metal tightly, giving you more accuracy. They also change quickly, saving you time. You get less chance of making mistakes because of how securely they grip. Overall, collets can make your work easier and cleaner.

How Do You Properly Set Up And Align A Cross Slide On A Metal Lathe For Precise Machining?To set up a cross slide on a metal lathe, start by cleaning the slide. Make sure it moves smoothly. Next, use a square tool to check if the slide is straight. You can adjust it by loosening the screws a bit. Finally, tighten the screws and double-check the alignment again to ensure it’s perfect.

What Factors Should Be Considered When Selecting A Specific Collet Size For A Particular Job On A Lathe?When choosing a collet size for a lathe, think about the size of the material you will work with. You want the collet to fit snugly around the item, so it doesn’t slip. Also, check the shape of the material. It should match the collet type for a good grip. Lastly, consider how much force you will need. A bigger collet can hold larger pieces more securely.

How Can Wear Or Misalignment In The Cross Slide Affect The Overall Precision Of Machining Operations On A Metal Lathe?If the cross slide on a metal lathe is worn out or not lined up correctly, it can make your cuts uneven. This means that the shapes we create may not be the right size or fit together properly. You might end up with parts that don’t match or work as they should. It’s important to keep the cross slide in good shape so we can make things accurately.

What Maintenance Practices Are Recommended For Keeping Both The Collet System And The Cross Slide In Optimal Working Condition?To keep the collet system and cross slide working well, you should clean them regularly. Use a soft cloth to wipe off dust and dirt. Apply a light oil to keep them moving smoothly. Check for any loose parts and tighten them if needed. Always keep everything dry to prevent rust.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems And Metal Lathe Cross Slides:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions you might ask about lathe collet systems and metal lathe cross slides: 1. What is a collet system? A collet system helps hold things tightly in place on a lathe. It keeps items steady while you work. 2. How does a lathe cross slide work? The cross slide is a part that moves side to side. It helps position the tool where you need it on the workpiece. 3. Why do we use collets instead of a chuck? Collets hold the material more securely than a regular chuck. They can also be faster to change. 4. Can I use different size collets? Yes! You can use different collets for different sizes of materials. Just change the collet to match what you’re using. 5. How do I care for my cross slide? Keep it clean and oiled. This helps it move smoothly and last longer.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Compared To A Standard Three-Jaw Chuck On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a collet system is better for some jobs than a three-jaw chuck. Collets hold the metal tightly, giving you more accuracy. They also change quickly, saving you time. You get less chance of making mistakes because of how securely they grip. Overall, collets can make your work easier and cleaner.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Cross Slide On A Metal Lathe For Precise Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a cross slide on a metal lathe, start by cleaning the slide. Make sure it moves smoothly. Next, use a square tool to check if the slide is straight. You can adjust it by loosening the screws a bit. Finally, tighten the screws and double-check the alignment again to ensure it’s perfect.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Specific Collet Size For A Particular Job On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a collet size for a lathe, think about the size of the material you will work with. You want the collet to fit snugly around the item, so it doesn’t slip. Also, check the shape of the material. It should match the collet type for a good grip. Lastly, consider how much force you will need. A bigger collet can hold larger pieces more securely.”}},{“@type”: “Question”,”name”: “How Can Wear Or Misalignment In The Cross Slide Affect The Overall Precision Of Machining Operations On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the cross slide on a metal lathe is worn out or not lined up correctly, it can make your cuts uneven. This means that the shapes we create may not be the right size or fit together properly. You might end up with parts that don’t match or work as they should. It’s important to keep the cross slide in good shape so we can make things accurately.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Recommended For Keeping Both The Collet System And The Cross Slide In Optimal Working Condition?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the collet system and cross slide working well, you should clean them regularly. Use a soft cloth to wipe off dust and dirt. Apply a light oil to keep them moving smoothly. Check for any loose parts and tighten them if needed. Always keep everything dry to prevent rust.”}}]}