Lathe Collet System: Essential Metal Lathe For Beginners

Lathe Collet System: A Beginner’s Guide

Are you new to metal lathes? A lathe collet system can make your work easier. Collets securely hold your tools. They come in different sizes. This means you can use various tools without hassle. Did you know many professionals prefer collets for their precision and speed? They help you achieve better results. Learning about lathe collets can boost your skills. It’s a fun way to dive into the world of metalworking!What is a Lathe Collet System?

Definition and purpose of a lathe collet system. Differences between collets and other holding devices.A lathe collet system holds materials during machining. It helps keep pieces steady and secure. A collet is a type of clamp that molds around the workpiece. This is different from other tools like chucks. Chucks can be bulkier and less precise.

- Collets: Lightweight, fast, and precise.

- Chucks: Heavier, holds larger pieces, but less accurate.

Collet systems are great for beginners. They make using a metal lathe easier and more effective.

What are the advantages of using a lathe collet system?

Collet systems allow for better grip and accuracy, which is important in metalworking. They also make switching tools faster.

Benefits of Using a Collet System with a Metal Lathe

Increased precision and repeatability in machining. Ease of use and quick tool changes for beginners.Using a collet system with a metal lathe is like having a trusty sidekick in your workshop! It helps make machining more precise, which means your parts fit perfectly every time. Beginners love it because changing tools is super quick and easy. No more struggling with stubborn clamps! You’ll be spinning your projects faster than you can say “lathe.” Plus, a collet system can turn those tricky tasks into smooth sailing!

| Benefits | Description |

|---|---|

| Precision | Helps produce exact parts that fit together nicely. |

| Easy Tool Changes | Switching tools is fast, keeping your workflow fun and smooth. |

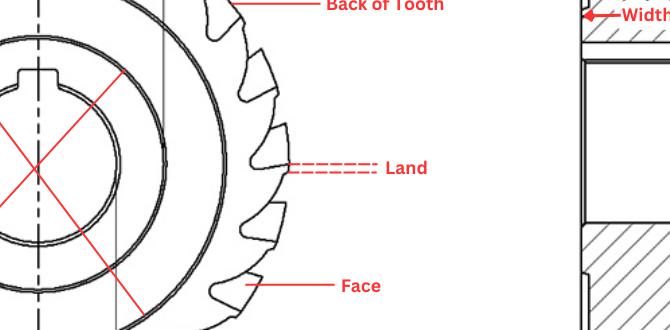

Components of a Lathe Collet System

Detailed breakdown of key components (collets, collet chuck, drawbar). Explanation of how each component contributes to the system’s function.A lathe collet system has a few important parts that work together. Collets hold the workpiece tightly. They can fit different shapes and sizes. Next is the collet chuck. This part connects the lathe to the collet. It keeps everything stable. Lastly, the drawbar pulls the collet into the chuck when secure. Each part ensures the tool works well. Without these, the lathe wouldn’t function properly.

What are the key components of a lathe collet system?

The main parts are collets, collet chuck, and drawbar.Understanding Each Component:

- Collets: They grip the workpiece.

- Collet Chuck: Holds the collet in place.

- Drawbar: Tightens the collet for a secure fit.

How to Choose the Right Collet for Your Metal Lathe

Factors to consider (size, type of workpiece, machine compatibility). Tips for beginners on selecting the best collet system.Choosing the right collet for a metal lathe can seem tricky. Start by considering the size and type of your workpiece. Next, check compatibility with your machine. Here are some tips:

- Measure your workpiece accurately.

- Pick the right collet type for your project, like ER or 5C.

- Ensure it fits your lathe model.

These steps help you find a collet that works well, making your metal lathe experience easier and more enjoyable.

What factors should I consider when choosing a collet?

The main factors to consider are size, type of workpiece, and machine compatibility. Measure everything carefully. Make sure the collet fits snugly and matches your project’s needs.

Setting Up Your Lathe Collet System

Stepbystep instructions for installation and calibration. Common mistakes to avoid during setup.Setting up a lathe collet system can be easy! Follow these steps for success:

- Remove the old chuck carefully.

- Clean the lathe’s spindle and surface.

- Mount the collet closer securely.

- Insert the collet and test for a good fit.

- Calibrate by checking alignment with a dial gauge.

Avoid common mistakes: don’t force the collet, check for dirt, and ensure tightness. These tips can save you time and frustration!

How do I avoid mistakes while setting up?

To avoid mistakes during setup, be sure to check that parts fit correctly and align properly. Clean surfaces first. Take your time to avoid rushing.

Maintenance Tips for Collet Systems

Best practices for cleaning and maintaining collets. How to troubleshoot common issues with collet systems.Taking care of collet systems is important for a smooth operation. Here are some easy tips:

- Clean them regularly: Use a soft brush and cloth to keep collets free from dust.

- Check for damage: Look for cracks or wear before use.

- Use lubrication: A little oil helps keep parts moving smoothly.

- Store properly: Keep collets in a dry, clean place.

If you face issues, here’s how to fix them:

- Slipping parts? Tighten them securely.

- Difficulty removing collets? Clean the threads.

- Warped collet? Replace it for safety.

By following these tips, you can keep your collet system in great shape. A well-maintained machine works better and lasts longer.

How do you maintain a lathe collet system?

To maintain a lathe collet system, regularly clean the collets, check for any damages, and apply lubrication to keep everything working smoothly.

What should you do if your collet is stuck?

If your collet is stuck, try cleaning the threads or lightly tapping it to loosen it.

Real-Life Applications of Collet Systems in Metalworking

Examples of projects and tasks suitable for beginners. Success stories or testimonials from users of collet systems.If you’re a newbie in metalworking, collet systems can be your best buddy. They’re great for holding various tools tightly, making them perfect for projects like creating small parts or making custom tools. Beginners often tackle fun tasks like making simple brackets or unique keychains. Many users rave about how collets made their work easier. One happy beginner said, “My projects don’t fly off the machine anymore!”

| Project | Task | Success Story |

|---|---|---|

| Keychain | Shaping and engraving | A teen made one for every friend! |

| Bracket | Cutting and fitting | A beginner fixed his bike! |

Conclusion

In summary, a lathe collet system is a great tool for beginners using a metal lathe. It holds workpieces tightly and accurately. Understanding how to use it can improve your projects. Start practicing with simple tasks and explore more resources to learn. Remember, the more you work with it, the better you’ll become. Happy turning!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Collet Systems For Metal Lathes, Particularly Aimed At Beginners:Sure! Here’s a simple explanation about lathe collet systems. A collet is a tool that holds things tight. It grips the metal piece you want to work on. Using a collet helps you make precise cuts. It’s faster than other methods because you can change pieces quickly. Remember to choose the right size collet for your work!

Sure! Please provide the question you’d like me to answer, and I’ll help you with that.

What Is A Lathe Collet System, And How Does It Differ From Traditional Chuck Systems Used In Metal Lathes?A lathe collet system is a tool used to hold and grip metal pieces tightly. It is like a hug for the metal, keeping it steady while you work. This system is usually smaller and can hold different sizes of pieces better than a traditional chuck. A chuck is another tool that holds metal, but it’s bigger and can be less precise. So, collets can help us make better and more detailed shapes!

What Are The Advantages Of Using A Collet Chuck System For Holding Workpieces In A Metal Lathe?Using a collet chuck system is great for holding workpieces tightly and securely. It grips the pieces evenly, so they won’t move around. This helps us make accurate cuts. Collet chucks are easy to change, saving us time when we switch pieces. Plus, they can hold different shapes and sizes well, making our work more flexible.

How Do I Choose The Right Size And Type Of Collet For My Metal Lathe And The Materials I Am Working With?To pick the right collet for your metal lathe, start by checking the size of your lathe’s spindle. Next, look at the size of the material you will work with. If you’re using small pieces, choose a smaller collet. For larger materials, go for a bigger collet. Make sure to match the collet type to the material, like wood or metal, for the best grip.

What Is The Proper Procedure For Setting Up And Using A Collet System On A Metal Lathe To Ensure Accuracy And Safety?To set up a collet system on a metal lathe, start by turning off the machine. Next, take the right collet size for your workpiece and fit it into the spindle. Make sure it is tight and secure. Then, insert your piece into the collet and tighten it evenly. Always wear safety gear like goggles, and keep your hands away from moving parts. Before you start the lathe, double-check everything to ensure it’s safe and ready.

Are There Specific Maintenance Tips Or Best Practices For Keeping A Lathe Collet System In Good Working Condition?To keep a lathe collet system working well, you should clean it regularly. Remove any dust or chips after each use. Check for any wear or damage and replace parts if needed. Make sure to lubricate moving parts to help them work smoothly. Lastly, store the collets in a safe, dry place to avoid rust.