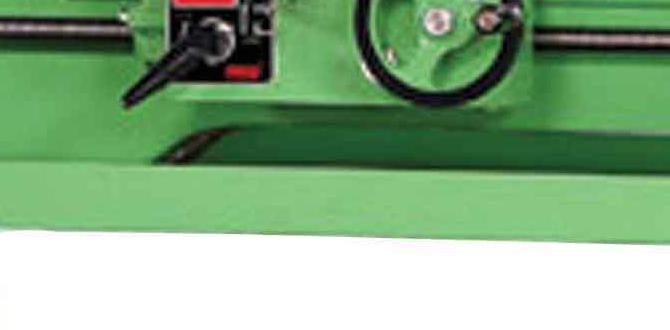

Have you ever watched a machine create shapes from metal? It’s fascinating! One key part of that process is the lathe collet system. This system plays a big role in how a metal lathe works, especially when it comes to the spindle.

Imagine you want to make a perfectly round piece of metal. How do you keep it steady? The answer lies in a good collet system. Collets help hold the metal tightly in place while the lathe shapes it. They make sure everything stays secure, leading to better results.

Did you know that using a collet can improve accuracy? It’s true! A metal lathe spindle with a strong collet system can turn out amazing products. So, if you’re interested in metalworking, understanding this system is key.

In this article, we will explore the lathe collet system and its importance in metal lathe spindles. Get ready to discover how this simple piece of equipment makes a big difference in machining!

Lathe Collet System: Essential For Metal Lathe Spindle Performance

Lathe Collet System for Metal Lathe Spindle

A lathe collet system is vital for metal lathes. It holds workpieces securely while spinning. This feature allows for greater precision and better finishes on projects. Did you know that using a collet can improve your lathe’s speed and reduce vibrations? Many hobbyists appreciate how easy it is to change tools with a collet system. It’s a game-changer for anyone looking to enhance their metalworking experience!What is a Lathe Collet System?

Definition and purpose of a collet system in metal lathes. Comparison between collets and other clamping systems.A collet system holds round objects tightly in place. It grips workpieces better than regular clamps. The benefits of a collet system include:

- Quick changes: Easily swap tools or materials.

- Better grip: It holds items more securely.

- Less runout: More precision while working.

Compared to other clamping systems, collets are usually smaller and can fit in tighter spaces. This makes them useful for detailed work on metal lathes.

What is a collet system used for?

A collet system is mainly used to hold and rotate metal pieces accurately. It helps in making precise cuts and shapes. This system makes tasks like turning and drilling much easier.

Benefits of Using a Collet System for Metal Lathes

Increased precision and accuracy in machining. Improved workpiece clamping and versatility.Using a collet system with metal lathes is like having a magic wand for your projects! First, it offers increased precision and accuracy, helping you create flawless pieces. Your work will fit together as snugly as a puzzle, without those annoying gaps. Plus, these collets improve workpiece clamping and add versatility. You can easily switch between tasks, making it feel like you’re the superhero of machining!

| Benefits | Description |

|---|---|

| Increased Precision | Ensures accurate cuts and smooth finishes |

| Improved Clamping | Holds pieces securely for better results |

| Versatility | Quickly adapt to different tasks and sizes |

How to Choose the Right Collet for Your Metal Lathe

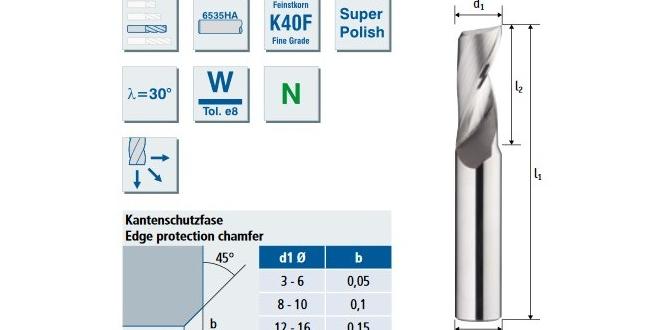

Factors to consider (size, material, application). Tips for matching collets with lathe specifications.Choosing the right collet for your metal lathe is important. Here are key factors to think about:

- Size: Ensure the collet fits your workpiece perfectly.

- Material: Consider what your job needs. Steel or aluminum might be best.

- Application: Use the right collet for the task at hand.

To match collets with lathe specifications, check the dimensions closely. Make sure the type of collet is compatible with your machine. A proper fit leads to smoother operation and better results.

Why is the right collet important?

Using the right collet can improve precision in your projects. It ensures safety and efficiency. Better fitting tools help you achieve a clean finish on your work.

Quick tips for choosing collets:

- Check your lathe’s manual for specifications.

- Consult experts for recommendations.

- Always try collets before making a final choice.

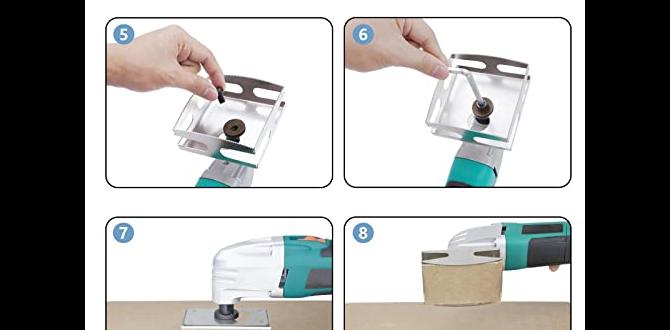

Setting Up a Collet System on Your Lathe Spindle

Stepbystep guide on installation and alignment. Common mistakes to avoid during setup.To set up your collet system on the lathe spindle, follow these steps. First, clean all parts thoroughly. Next, attach the collet to the spindle with a wrench. Tighten it snugly but do not overdo it. Align the spindle carefully to avoid any misplacement. Common mistakes include not cleaning parts or overtightening the collet. These issues can lead to problems later. Always double-check alignment for smooth operation.

What are the common mistakes during setup?

Here are some mistakes to avoid:

- Not cleaning parts carefully.

- Overtightening the collet.

- Misaligning the spindle.

- Forgetting to check part compatibility.

Remember, careful setup ensures better performance. A well-aligned system can boost the efficiency of your lathe.

Maintenance Tips for Collet Systems

Best practices for cleaning and maintaining collets. Signs of wear and how to replace collets properly.Keeping your collet system in great shape is key for smooth work. To clean your collets, use a soft cloth and mild cleaner. Avoid using metal tools, as they can scratch. Inspect for signs of wear, like cracks or deformation. Replace any worn collets as soon as possible. Follow the steps below for proper replacement:

- Turn off the lathe.

- Remove the old collet carefully.

- Insert the new collet into the spindle.

- Secure it tightly.

By following these steps, your metal lathe will run better and last longer!

How do you know when collets need to be replaced?

You should replace a collet if it shows signs of serious wear, like cracks or loss of grip. Regular checks help you catch problems early.

Applications of Collet Systems in Metalworking

Examples of industries and projects that benefit from collet systems. Case studies showcasing successful implementations.Many industries use collet systems in metalworking. These systems help hold workpieces tightly and accurately. Industries like aerospace, automotive, and manufacturing benefit greatly. For instance:

- Aerospace: Collets secure intricate parts for planes.

- Automotive: They help create precise engine components.

- Manufacturing: Collets improve production speed and quality.

Companies report that using collet systems leads to less waste and fast production. A case study showed a 30% boost in efficiency for a car parts maker. This shows how collets make work easier and better.

What industries benefit from collet systems?

Aerospace, automotive, and manufacturing industries benefit from collet systems. These systems enhance precision and speed in production tasks, leading to improved results.

Frequently Asked Questions About Lathe Collet Systems

Common queries and detailed answers on collets and usage. Clarifications on myths and misconceptions related to collet systems.Many people wonder about collet systems and their magic. One common question is: “What is a collet?” A collet is a handy tool that grips materials tight, helping the lathe work smoothly. Another question might be: “Can any tool fit any collet?” Nope! Each collet has a specific size, just like shoes! Now, about the myth that all collets are the same: not true! Good collets can hold things very tightly without slipping. If you’re confused, just remember: the right collet makes the job easier!

| Question | Answer |

|---|---|

| What does a collet do? | It holds tools in place on the lathe. |

| Are collets universal? | No, each type fits specific sizes! |

| Do collets wear out? | Yes, but with good care, they last longer! |

Conclusion

In summary, a lathe collet system helps hold metal pieces securely while you work. It fits snugly into the spindle of your lathe, making your projects more precise. You can choose different sizes based on your needs. Remember to consider your specific tasks when selecting a collet. For more tips, keep exploring resources on lathe tools and techniques!FAQs

Here Are Five Related Questions On The Topic Of Lathe Collet Systems For Metal Lathe Spindles:Lathe collet systems help hold parts in place while you work. They fit snugly around the piece you’re shaping. This keeps everything steady and prevents it from moving. Using collets can make your work more precise and easier. They are especially great for small items.

Sure! Please provide the question you want answered, and I’ll be happy to help.

What Are The Advantages Of Using A Collet System Over A Three-Jaw Chuck In A Metal Lathe Spindle?A collet system holds things tighter than a three-jaw chuck. This means your workpiece won’t slip while you’re shaping it. Collets are easier to change, so you can switch quickly between different sizes. They also make a cleaner cut, giving you smoother results. Overall, using a collet helps you work better and faster!

How Do Different Types Of Collets, Such As Er Collets And Collets, Compare In Terms Of Clamping Force And Versatility?ER collets and other types of collets help hold tools tightly. ER collets provide strong clamping force, so they keep tools from slipping. They are also very versatile, meaning you can use them with many different tool sizes. Other collets might not grip as tightly or fit as many tools. So, ER collets are often the better choice for many jobs.

What Factors Should Be Considered When Selecting A Collet System For A Specific Metal Lathe Application?When choosing a collet system for a metal lathe, think about the size you need. You should also consider the type of metal you will work with. Different collets hold different shapes and sizes of metal. Make sure the collet system fits your lathe well. Lastly, think about how easy it is to use and change the collets.

How Do You Properly Maintain And Troubleshoot Collet Systems In Metal Lathes To Ensure Optimal Performance?To keep collet systems in metal lathes working well, you should clean them often. Use a soft cloth to wipe off dust and dirt. Check if the collet grips the metal piece tightly. If it feels loose, try adjusting or replacing it. If something isn’t working right, look for any cracks or wear. Fix or change broken parts to keep everything running smoothly.

What Are Some Common Materials Used For Collets, And How Do They Affect The Precision And Durability Of The Lathe Setup?Collets are often made from metal, like steel or aluminum. Steel collets are strong and last a long time. Aluminum collets are lighter but not as strong. The material you choose affects how well the lathe works. Better materials help the machine hold parts tightly and cut more accurately.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Collet Systems For Metal Lathe Spindles:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Lathe collet systems help hold parts in place while you work. They fit snugly around the piece you’re shaping. This keeps everything steady and prevents it from moving. Using collets can make your work more precise and easier. They are especially great for small items.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want answered, and I’ll be happy to help.”}},{“@type”: “Question”,”name”: “What Are The Advantages Of Using A Collet System Over A Three-Jaw Chuck In A Metal Lathe Spindle?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A collet system holds things tighter than a three-jaw chuck. This means your workpiece won’t slip while you’re shaping it. Collets are easier to change, so you can switch quickly between different sizes. They also make a cleaner cut, giving you smoother results. Overall, using a collet helps you work better and faster!”}},{“@type”: “Question”,”name”: “How Do Different Types Of Collets, Such As Er Collets And Collets, Compare In Terms Of Clamping Force And Versatility?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “ER collets and other types of collets help hold tools tightly. ER collets provide strong clamping force, so they keep tools from slipping. They are also very versatile, meaning you can use them with many different tool sizes. Other collets might not grip as tightly or fit as many tools. So, ER collets are often the better choice for many jobs.”}},{“@type”: “Question”,”name”: “What Factors Should Be Considered When Selecting A Collet System For A Specific Metal Lathe Application?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a collet system for a metal lathe, think about the size you need. You should also consider the type of metal you will work with. Different collets hold different shapes and sizes of metal. Make sure the collet system fits your lathe well. Lastly, think about how easy it is to use and change the collets.”}},{“@type”: “Question”,”name”: “How Do You Properly Maintain And Troubleshoot Collet Systems In Metal Lathes To Ensure Optimal Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep collet systems in metal lathes working well, you should clean them often. Use a soft cloth to wipe off dust and dirt. Check if the collet grips the metal piece tightly. If it feels loose, try adjusting or replacing it. If something isn’t working right, look for any cracks or wear. Fix or change broken parts to keep everything running smoothly.”}},{“@type”: “Question”,”name”: “What Are Some Common Materials Used For Collets, And How Do They Affect The Precision And Durability Of The Lathe Setup?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Collets are often made from metal, like steel or aluminum. Steel collets are strong and last a long time. Aluminum collets are lighter but not as strong. The material you choose affects how well the lathe works. Better materials help the machine hold parts tightly and cut more accurately.”}}]}