Lathe Compound Rest Custom Scale: Enhance Your Precision

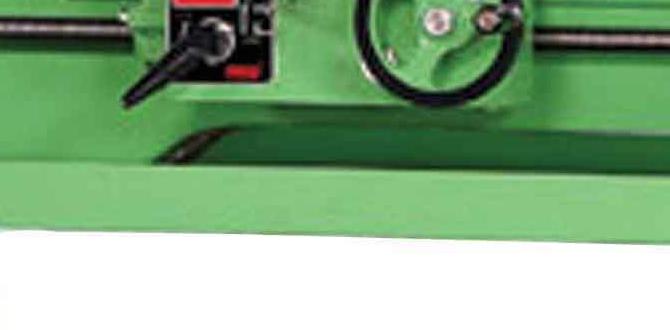

Lathe Compound Rest Custom Scale

Custom scales on a lathe’s compound rest enhance precision. What if you could measure with perfect accuracy? This upgrade allows for better control when shaping materials. Users find that custom scales simplify complex projects. Imagine effortlessly adjusting your settings for intricate designs! Many woodworkers and metalworkers enjoy this feature for its time-saving benefits. Plus, did you know that a simple scale can transform your workspace? Custom scales unlock new possibilities for creativity and efficiency in lathe work.What is a Lathe Compound Rest?

Definition and function of the compound rest in a lathe. Importance of the compound rest in machining processes.A lathe compound rest is a key part of a lathe machine. It allows the tool to move smoothly in different directions. This is important for making accurate cuts. Think of it like a magic carpet for tools—smooth and precise!

The compound rest helps shape materials by letting you adjust the angle and depth of cuts. Without it, making complex shapes would be like trying to bake without a pan—messy and hard!

| Function | Importance |

|---|---|

| Lets tool move freely | Ensures accuracy |

| Adjusts cutting angles | Creates precise shapes |

So, remember, the compound rest isn’t just a fancy name—it’s essential for every mini machinist out there!

Benefits of Installing a Custom Scale

Enhanced precision in measurements and adjustments. Improved workflow and efficiency during operations.Adding a custom scale to your lathe can work wonders! First, it brings greater precision to your measurements and adjustments. You won’t believe how this little change can make such a big difference. Second, it streamlines your workflow, boosting efficiency during operations. Less time guessing means more time creating. And remember: “Why measure twice when you can measure once and still get it right?”

| Benefit | Description |

|---|---|

| Precision | Improves accuracy in every cut and adjustment. |

| Efficiency | Enhances speed, letting you focus on design instead of number crunching. |

How to Measure and Mark for Custom Scale Installation

Tools required for accurate measurement. Stepbystep guide to marking and preparing surfaces.To get started with your custom scale, you need a few handy tools. Grab a measuring tape, a marker, and a square. These will help you measure accurately and mark well. Ready? Let’s break it down!

First, measure the area where the scale goes. Use your measuring tape and ensure it’s straight—no one wants a wiggly scale! Next, use your square to mark straight lines on the surface. Remember, a good line is like a good joke—perfectly straight!

| Tools Needed | Purpose |

|---|---|

| Measuring Tape | To measure distance |

| Marker | To mark your measurements |

| Square | To create straight lines |

With your tools ready, mark where your custom scale will go. Double-check those measurements! If you mess up, it’s like telling a bad joke—you’ll have to fix it.

Installation Process of a Custom Scale on Compound Rest

Detailed instructions on installation steps. Common mistakes to avoid during installation.Setting up a custom scale on your lathe’s compound rest is like following a fun treasure map! First, gather your tools: a screwdriver, ruler, and maybe a donut for energy. Start by measuring the rest accurately to avoid errors. Attach the scale carefully using the right screws. A common mistake is skipping the alignment step—don’t be that person! Double-check that everything is level. Lastly, wipe that donut glaze off your hands before you touch tools! Stay focused, and soon you’ll be measuring like a pro.

| Installation Steps | Common Mistakes |

|---|---|

| Measure the compound rest. | Forgetting to align the scale properly. |

| Attach the scale securely. | Using the wrong screws. |

| Ensure everything is level. | Skipping the double-check. |

Adjusting and Calibrating the Custom Scale

Importance of calibration for accuracy. Stepbystep calibration process.Calibrating your custom scale is important for getting accurate measurements on your lathe. Without proper calibration, you might end up with incorrect cuts. Here’s a simple process to calibrate your scale:

- Check the scale against a known measurement.

- Adjust the scale until it matches exactly.

- Test it several times to ensure accuracy.

Regular calibration keeps your lathe running smoothly and saves time in the long run. Remember, accuracy leads to better projects!

Why is calibration important?

Calibration ensures that your measurements are correct, leading to better results. Accurate measurements can make a big difference in your work.

Maintenance Tips for Longevity of Custom Scales

Recommended cleaning methods and schedule. Best practices to avoid wear and tear.Keeping custom scales clean and safe helps them last longer. Here are simple tips:

- Use a soft cloth to wipe off dust weekly.

- Apply a tiny amount of oil every month to keep parts moving smoothly.

- Avoid dropping or hitting the scale.

- Store it in a dry place to prevent rust.

- Check for damage regularly and fix it right away.

With proper care, your lathe compound rest custom scale will work well for many years.

How often should I clean my custom scale?

You should clean your custom scale at least once a week. This keeps it dust-free and ready to use!

Cleaning Methods:

- Soft cloth for dust.

- Gentle soap if needed.

Common Issues and Troubleshooting with Custom Scales

Identifying typical problems faced by users. Solutions and fixes for common issues.Every tool has its quirks, and custom scales are no exception. Users often face issues like inaccurate readings or stuck adjustments. Thankfully, many problems have simple fixes! For inaccurate measurements, ensure the scale is zeroed. If it won’t move, check for debris. A good cleaning can work magic. Here’s a quick table for common issues:

| Problem | Solution |

|---|---|

| Inaccurate reading | Re-zero the scale |

| Stuck adjustment | Clean debris around the mechanism |

| Difficulty reading scale | Ensure good lighting |

Remember, a bit of patience goes a long way. With these tricks, your lathe will run smoother than a sliding penguin on ice!

Real-Life Applications and Case Studies

Examples of industries utilizing custom scales on lathes. Success stories highlighting precision improvements.Many businesses use custom scales on lathes. For example, the automotive industry relies on precision parts for safety and performance. The electronics sector needs tiny components manufactured accurately. Companies report great success with these tools. They achieve better measurements, which leads to improved quality. This can save money and time. Here are some success stories:

- Company A decreased errors by 30%.

- Company B cut production time by half.

- Company C improved customer satisfaction significantly.

What industries use custom scales on lathes?

Industries like automotive, electronics, and machinery rely on custom scales to enhance precision and efficiency.

Conclusion

In summary, a custom scale on a lathe’s compound rest helps you make precise cuts. It improves accuracy and eases measurements. If you’re working with lathes, consider creating one for your projects. You can enhance your skills and make your work easier. Explore more about lathe techniques and custom tools to elevate your craftsmanship!FAQs

Sure! Here Are Five Questions Related To The Topic Of A Lathe Compound Rest Custom Scale:Sure! Here are five questions related to a lathe compound rest custom scale. 1. What is a lathe compound rest? A lathe compound rest is a part of a lathe machine. It helps you move and hold tools for cutting. 2. Why do we need a custom scale? We need a custom scale to measure distances accurately. It helps you set the tool where you want it. 3. How do you use the custom scale? You use the custom scale by reading its measurements. This tells you how far to move your tools. 4. Can we make our own scale? Yes, you can create your own custom scale. Just measure carefully and mark the distance. 5. How does the scale help with projects? The scale helps you be precise in your work. This means your projects will turn out better.

Sure! Please provide the question you would like me to answer.

What Materials Are Commonly Used For Creating A Custom Scale For A Lathe Compound Rest, And How Do They Affect Durability And Accuracy?You can make a custom scale for a lathe compound rest using materials like aluminum, steel, or plastic. Aluminum is lightweight and strong, making it easy to work with. Steel is very durable and helps the scale stay accurate over time. Plastic can be good too, but it might not last as long. Choosing the right material helps your scale last and give precise measurements.

How Can I Accurately Measure And Mark A Compound Rest To Install A Custom Scale Without Compromising The Lathe’S Precision?To measure and mark a compound rest on your lathe, first clean the area well. Then, use a ruler to find the center point. Carefully mark this spot with a fine, sharp pencil. Make sure to double-check your measurements to keep everything accurate. Finally, when you install the scale, make sure it is level and straight. This helps keep your lathe working precisely!

What Are The Benefits Of Having A Custom Scale On A Lathe Compound Rest Compared To Using The Standard Scale Provided By The Manufacturer?Having a custom scale on a lathe compound rest helps you measure more accurately. You can see the numbers clearly, making it easier to set things right. Custom scales can fit better with your projects, so you don’t waste time. They may also show measurements that matter more for your work. Overall, it helps you make better parts faster!

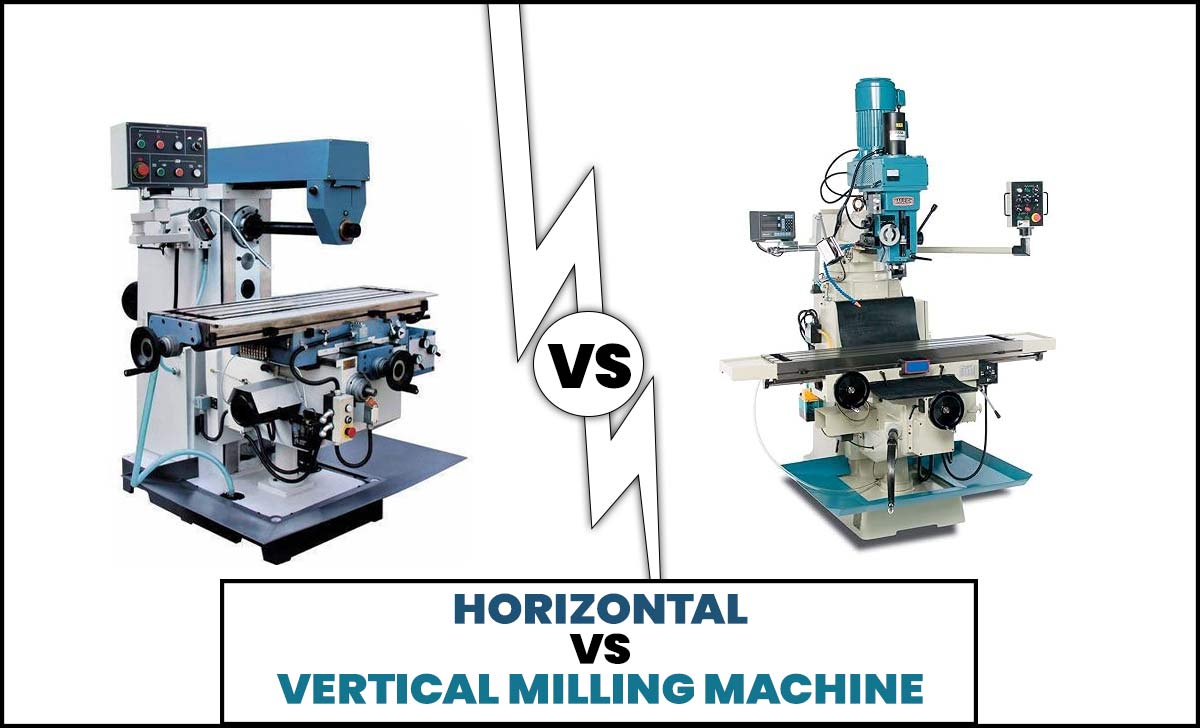

What Types Of Measuring Systems (E.G., Digital Vs. Manual) Can Be Integrated Into A Custom Scale For Lathe Compound Rests, And What Features Should I Consider?You can use digital measuring systems or manual measuring tools on a lathe compound rest. Digital systems show numbers on a screen, making it easy to read. Manual systems use traditional rulers or sliding scales, which you read yourself. When choosing, think about ease of use, how accurate the measurements are, and whether it’s easy to install. You want something that helps you work better and is simple to understand.

How Can I Ensure That My Custom Scale Remains Calibrated Over Time, And What Maintenance Practices Should I Implement To Prevent Wear And Misalignment?To keep your custom scale working well, you should check it regularly. We can do this by weighing known weights to see if it measures correctly. You should also clean it often to prevent dirt from causing problems. Store your scale in a safe place, away from heavy objects. Finally, make sure it’s on a flat surface so it doesn’t get misaligned.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To The Topic Of A Lathe Compound Rest Custom Scale:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five questions related to a lathe compound rest custom scale. 1. What is a lathe compound rest? A lathe compound rest is a part of a lathe machine. It helps you move and hold tools for cutting. 2. Why do we need a custom scale? We need a custom scale to measure distances accurately. It helps you set the tool where you want it. 3. How do you use the custom scale? You use the custom scale by reading its measurements. This tells you how far to move your tools. 4. Can we make our own scale? Yes, you can create your own custom scale. Just measure carefully and mark the distance. 5. How does the scale help with projects? The scale helps you be precise in your work. This means your projects will turn out better.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you would like me to answer.”}},{“@type”: “Question”,”name”: “What Materials Are Commonly Used For Creating A Custom Scale For A Lathe Compound Rest, And How Do They Affect Durability And Accuracy?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can make a custom scale for a lathe compound rest using materials like aluminum, steel, or plastic. Aluminum is lightweight and strong, making it easy to work with. Steel is very durable and helps the scale stay accurate over time. Plastic can be good too, but it might not last as long. Choosing the right material helps your scale last and give precise measurements.”}},{“@type”: “Question”,”name”: “How Can I Accurately Measure And Mark A Compound Rest To Install A Custom Scale Without Compromising The Lathe’S Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To measure and mark a compound rest on your lathe, first clean the area well. Then, use a ruler to find the center point. Carefully mark this spot with a fine, sharp pencil. Make sure to double-check your measurements to keep everything accurate. Finally, when you install the scale, make sure it is level and straight. This helps keep your lathe working precisely!”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Having A Custom Scale On A Lathe Compound Rest Compared To Using The Standard Scale Provided By The Manufacturer?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Having a custom scale on a lathe compound rest helps you measure more accurately. You can see the numbers clearly, making it easier to set things right. Custom scales can fit better with your projects, so you don’t waste time. They may also show measurements that matter more for your work. Overall, it helps you make better parts faster!”}},{“@type”: “Question”,”name”: “What Types Of Measuring Systems (E.G., Digital Vs. Manual) Can Be Integrated Into A Custom Scale For Lathe Compound Rests, And What Features Should I Consider?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You can use digital measuring systems or manual measuring tools on a lathe compound rest. Digital systems show numbers on a screen, making it easy to read. Manual systems use traditional rulers or sliding scales, which you read yourself. When choosing, think about ease of use, how accurate the measurements are, and whether it’s easy to install. You want something that helps you work better and is simple to understand.”}},{“@type”: “Question”,”name”: “How Can I Ensure That My Custom Scale Remains Calibrated Over Time, And What Maintenance Practices Should I Implement To Prevent Wear And Misalignment?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep your custom scale working well, you should check it regularly. We can do this by weighing known weights to see if it measures correctly. You should also clean it often to prevent dirt from causing problems. Store your scale in a safe place, away from heavy objects. Finally, make sure it’s on a flat surface so it doesn’t get misaligned.”}}]}