If you work with lathes, you know how important the compound rest position is. Have you ever struggled to get it just right? You’re not alone. Many beginners face this challenge. One small mistake can affect the whole project!

Imagine crafting a beautiful piece of wood. You carefully set everything up. But then, your tool slips because the compound rest isn’t positioned well. Frustrating, isn’t it?

Here’s a fun fact: the compound rest can make or break your project. A good position leads to smoother cuts and cleaner finishes. It really does help!

In this article, we’ll share some useful tips on the lathe compound rest position. You’ll learn how to adjust it like a pro. Get ready to improve your skills and have more fun working with lathes!

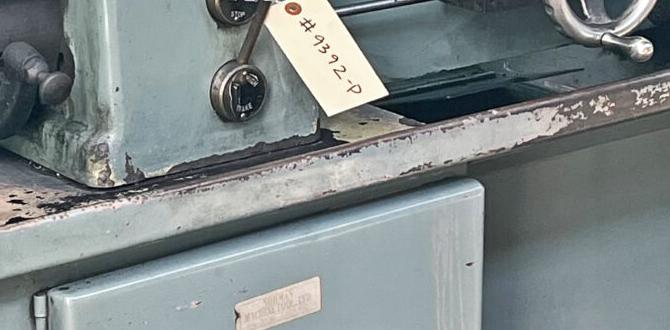

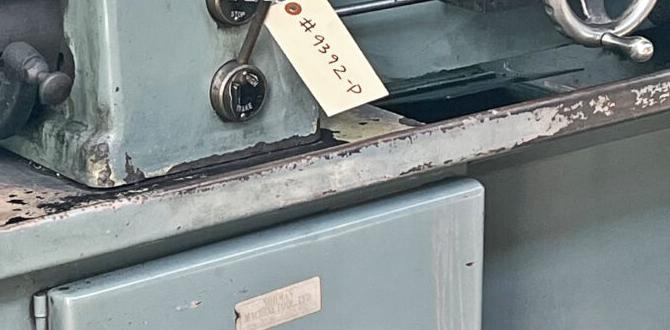

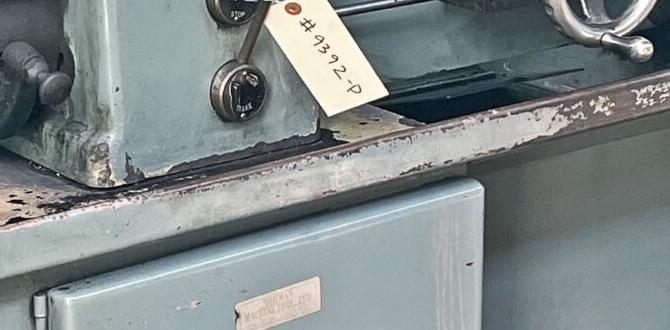

Lathe Compound Rest Position Tips For Precision Machining

Lathe Compound Rest Position Tips

Positioning the lathe compound rest correctly is crucial for successful turning. Adjusting its angle can enhance cutting precision. Always ensure the rest supports your workpiece securely. Did you know that a slight misalignment can lead to uneven cuts? It’s like drawing with a wobbly pencil! Using a good reference point helps in achieving accuracy. Remember, take your time to make adjustments. Simple tweaks can make a big difference in your projects. Happy turning!Key Factors Influencing Compound Rest Positioning

Discuss the role of workpiece size and shape. Importance of cutting tool angle and height in positioning.Workpiece size and shape are key in setting the compound rest. Bigger pieces need more space. Odd shapes may require different angles for cutting. A correct tool angle helps make smoother cuts. Height matters too; it ensures the tool fits well with the workpiece. This balance is crucial for successful machining.

What should I consider for positioning?

Many factors affect positioning, like :

- Workpiece dimensions: Larger pieces need adjustments.

- Tool angle: It determines the cut’s quality.

- Tool height: Appropriate height aids precision.

Using the right settings boosts efficiency. Good positioning leads to clean cuts and better results. Remember, small changes can make a big difference!

Tips for Accurate Positioning of the Compound Rest

Stepbystep guide to setting the compound rest correctly. Common mistakes to avoid when positioning.Getting the compound rest set up right is like finding the perfect slice of cake—nobody wants to mess that up! Start by loosening the compound rest lock. Move it to the desired angle using the dials. Always double-check with a protractor for precision; even a degree off can lead to disaster! Keep an eye out for common mistakes like forgetting to tighten the lock. Don’t be that guy who has to redo everything!

| Common Mistakes | Tips to Avoid Them |

|---|---|

| Not checking angles | Use a protractor! |

| Loose adjustments | Tighten everything securely. |

| Ignoring measurements | Always measure twice. |

With this guide, your compound rest positioning will be spot on. Now, go forth and make some marvelous pieces of art! Or at least, try not to turn your project into a mystery science experiment.

Tools and Techniques for Enhanced Precision

Recommended tools for measuring and aligning the compound rest. Techniques to achieve fine adjustments for better results.Getting the right tools makes a big difference. For measuring and aligning the compound rest, here are some must-haves:

- **Calipers** – They help measure distances accurately.

- **Dial Indicators** – These show tiny movements and help with precise adjustments.

- **Leveling Gages** – Ensures everything is straight and true.

- **Alignment Jigs** – These can guide your setup smoothly.

To achieve fine adjustments, try these techniques:

- **Small Movements** – Make tiny changes at a time.

- **Check Often** – Measure regularly to stay on track.

- **Use Visual Cues** – Keep an eye on markings for better alignment.

With the right tools and some practice, you can master your lathe setup.

What tools help in lathe setup?

For lathe setup, use tools like **calipers, dial indicators**, and **leveling gages**. These tools help measure and align parts accurately for better results.

Common Problems and Solutions with Compound Rest Positioning

Typical issues faced when positioning the compound rest. Troubleshooting tips to resolve positioning errors.Positioning the compound rest can feel tricky, like trying to solve a Rubik’s cube blindfolded. Common problems arise when it’s not aligned correctly, which can lead to uneven cuts. If you notice that your workpiece isn’t smooth, it’s time to check that positioning. Use the table below for quick troubleshooting tips:

| Problem | Solution |

|---|---|

| Compound rest wobbling | Tighten all adjusting screws. |

| Misalignment | Use a dial indicator to check angles. |

| Chatter marks on workpiece | Adjust speed and tool pressure. |

Remember, practice makes perfect! The more you adjust and learn, the less you’ll resemble a toddler trying to color inside the lines.

Best Practices for Maintenance of the Compound Rest

Regular maintenance tips to ensure longevity. Recommended cleaning methods and lubrication practices.Keeping the compound rest in good shape is essential for your lathe. Regular checks help it last longer. Clean it often with a soft cloth and some oil. This keeps parts smooth and prevents rust. Use the right lubricant on the moving parts; it helps them work better. Here are some tips to keep everything running well:

- Clean regularly to remove dust.

- Lubricate moving parts monthly.

- Check for wear and tear often.

How often should you clean your lathe?

You should clean your lathe after every use or at least once a week. Regular cleaning helps avoid dirt buildup and keeps it running smoothly.

Conclusion

In conclusion, properly positioning your lathe compound rest is crucial for precise machining. Remember to adjust it for better control and accuracy. Check your alignment often and practice adjusting it. You can improve your skills with hands-on experience. For more tips and tricks, consider reading more about lathe operations online. Happy turning!FAQs

Sure! Here Are Five Questions Related To Lathe Compound Rest Position Tips:Sure! Here are some tips for using a lathe’s compound rest. First, always ensure the compound rest is locked in place before you start. This helps keep everything steady. Second, adjust the angle carefully to get the cut you want. Third, check the tool height to make sure it’s just right. Lastly, remember to practice safety by wearing goggles and keeping hands clear of the cutting area.

Sure! Please provide me with the question you want answered.

What Is The Optimal Angle To Set The Compound Rest For Turning Tapered Workpieces On A Lathe?To turn tapered pieces on a lathe, you should set the compound rest at an angle. This angle is usually around 1 to 2 degrees for each inch you want to taper. If the taper is long, you might need a bigger angle. Keep it small and steady for nicer shapes. Make sure to measure carefully for the best results!

How Can Adjusting The Compound Rest Position Improve The Accuracy Of Cuts On A Lathe?Adjusting the compound rest on a lathe helps you make better cuts. When you change its angle, you can cut at more precise spots. This makes the shapes you create fit together better. Better cuts mean your projects turn out just how you want them. It’s like being a craftsman who knows exactly what to do!

What Are The Common Mistakes To Avoid When Positioning The Compound Rest For A Specific Machining Operation?When you set up the compound rest, avoid these mistakes. First, don’t forget to check the angle. If it’s wrong, your cut won’t be straight. Second, make sure it’s tight so it doesn’t move while you work. Third, remember to measure carefully before starting. These steps help you make better cuts and keep everything safe!

How Does The Position Of The Compound Rest Affect The Tool’S Cutting Action And Surface Finish?The compound rest is a part of a machine tool that holds the cutting tool. When you change its position, it can tilt the tool. This helps the tool cut in different ways. If you angle it right, the tool makes a smoother finish on the surface. So, the way you set the compound rest really matters for how well the cutting tool works!

What Techniques Can Be Used To Secure The Compound Rest In Place For Enhanced Stability During Machining?To keep the compound rest stable during machining, you can use several techniques. First, make sure to tighten all screws and bolts securely. Second, you can use clamps to hold it in place tightly. Third, check for any loose parts and fix them. Lastly, keeping your machine clean helps it work better and stay stable.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Compound Rest Position Tips:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are some tips for using a lathe’s compound rest. First, always ensure the compound rest is locked in place before you start. This helps keep everything steady. Second, adjust the angle carefully to get the cut you want. Third, check the tool height to make sure it’s just right. Lastly, remember to practice safety by wearing goggles and keeping hands clear of the cutting area.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you want answered.”}},{“@type”: “Question”,”name”: “What Is The Optimal Angle To Set The Compound Rest For Turning Tapered Workpieces On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To turn tapered pieces on a lathe, you should set the compound rest at an angle. This angle is usually around 1 to 2 degrees for each inch you want to taper. If the taper is long, you might need a bigger angle. Keep it small and steady for nicer shapes. Make sure to measure carefully for the best results!”}},{“@type”: “Question”,”name”: “How Can Adjusting The Compound Rest Position Improve The Accuracy Of Cuts On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Adjusting the compound rest on a lathe helps you make better cuts. When you change its angle, you can cut at more precise spots. This makes the shapes you create fit together better. Better cuts mean your projects turn out just how you want them. It’s like being a craftsman who knows exactly what to do!”}},{“@type”: “Question”,”name”: “What Are The Common Mistakes To Avoid When Positioning The Compound Rest For A Specific Machining Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When you set up the compound rest, avoid these mistakes. First, don’t forget to check the angle. If it’s wrong, your cut won’t be straight. Second, make sure it’s tight so it doesn’t move while you work. Third, remember to measure carefully before starting. These steps help you make better cuts and keep everything safe!”}},{“@type”: “Question”,”name”: “How Does The Position Of The Compound Rest Affect The Tool’S Cutting Action And Surface Finish?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest is a part of a machine tool that holds the cutting tool. When you change its position, it can tilt the tool. This helps the tool cut in different ways. If you angle it right, the tool makes a smoother finish on the surface. So, the way you set the compound rest really matters for how well the cutting tool works!”}},{“@type”: “Question”,”name”: “What Techniques Can Be Used To Secure The Compound Rest In Place For Enhanced Stability During Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the compound rest stable during machining, you can use several techniques. First, make sure to tighten all screws and bolts securely. Second, you can use clamps to hold it in place tightly. Third, check for any loose parts and fix them. Lastly, keeping your machine clean helps it work better and stay stable.”}}]}