Have you ever wondered how to make your own metal lathe even better? Converting a regular lathe into a more powerful tool is an exciting project. A lathe conversion can be simple if you have the right controller board. These boards help control the lathe’s movements with precision.

Imagine turning a rough piece of metal into a smooth, perfect shape. It sounds cool, right? With the right lathe conversion, you can do just that! A good metal lathe controller board can change everything.

Did you know that many hobbyists and beginners achieve stunning results with lathe conversions? They create amazing projects, from custom parts to art pieces. This article will guide you through the process and show you how easy and rewarding it can be.

Are you ready to dive into the world of lathe conversions? Let’s explore how the right controller board can enhance your lathe experience!

Lathe Conversion: Upgrade Your Metal Lathe Controller Board

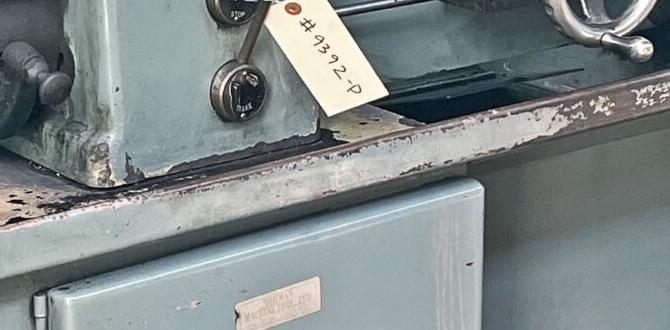

Lathe Conversion Metal Lathe Controller Board

Lathe conversion kits offer a great way to upgrade your metal lathe. They include a controller board, which helps you run your lathe with precision. With a good controller, you can easily adjust speeds and settings. This makes it easier to create accurate cuts. Imagine turning your aging machine into a high-tech tool! Many users find these conversions rewarding, leading to better projects and greater satisfaction. Why settle for less when you can elevate your lathe experience?Understanding Lathe Conversion

Definition and purpose of lathe conversion. Benefits of converting a standard lathe to a CNC lathe.Lathe conversion means changing a regular lathe into a Computer Numerical Control (CNC) lathe. This upgrade helps in making precise and complex cuts in metal or wood. By using a metal lathe controller board, users can automate tasks. Benefits of CNC lathes include:

- Improved accuracy

- Faster production

- Less manual effort

- Ability to create detailed designs

This conversion opens a world of creativity. Hobbyists and professionals can work with special features that make crafting easier and fun.

What are the benefits of converting to a CNC lathe?

Converting to a CNC lathe offers greater speed, accuracy, and efficiency. It allows for complex shapes and designs that would be hard to achieve with a manual lathe.

Key Features to Look for in a Controller Board

Responsiveness and precision. Compatibility with different lathe models. Software support and ease of use.Choosing the right controller board can really make or break your lathe experience. You’ll want something that offers responsiveness and precision, so cuts are clean and smooth, not like a wobbly dance! Make sure it’s compatible with your lathe model—nobody wants a board that says, “I’m sorry, I don’t speak your machine’s language.” Also, look for software that’s user-friendly because no one has time for a tech puzzle. Remember, keeping things simple can save you from a lathe-related headache!

| Feature | Importance |

|---|---|

| Responsiveness | Ensures smooth operation and precise cuts |

| Compatibility | Works with various lathe models for flexibility |

| Software Support | Simplifies operation and enhances user experience |

Installation Process for Controller Boards

Stepbystep guide to installing a controller board. Common challenges and troubleshooting tips.Installing a controller board can be fun and exciting! Follow these simple steps to get started:

- First, gather your tools. You’ll need a screwdriver and some wires.

- Next, disconnect old parts carefully to avoid damage.

- Then, attach the new controller board using screws. Make sure it is secure!

- After that, connect all wires according to the instructions.

- Finally, test the setup to ensure everything works.

If you face challenges, don’t worry! Common issues include loose connections and wrong wiring. Tightening connections often helps. If the board doesn’t turn on, double-check the power supply.

What should I do if my controller board won’t turn on?

First, check the power supply. Make sure it’s plugged in and working. Next, examine the wiring for any loose connections. Lastly, reset the board by disconnecting and reconnecting it.

Upgrading Your Controller Board: When and Why

Signs that it’s time for an upgrade. Potential improvements in functionality and output quality.Noticing strange sounds or slow movements from your machine? It may be time for an upgrade. A new controller board can solve many issues. Look for these signs:

- Poor accuracy in cuts

- Frequent errors during operation

- Difficulty in programming tasks

Upgrading can also improve your machine’s functionality. You may notice:

- Smoother operation

- Better precision

- Enhanced speed

Your projects will look and feel much better!

How do I know if I need an upgrade?

Look for performance problems, strange noises, or delays in your machine. These signs often suggest it’s time for a new controller board!

Cost Considerations for Lathe Conversion

Breakdown of expenses involved in controller board conversion. Costeffectiveness compared to purchasing a new CNC lathe.Convert your lathe without breaking the bank! The costs can vary, but let’s break it down. Usually, you’ll need a controller board, cables, and maybe some sensors. Think of it like a lathe’s makeover—adding bling without the hefty price tag of a new CNC lathe. Sometimes, a conversion could save you up to 50% of the cost. That’s like finding a bonus cookie in your lunch! Check out the table below for a quick expense overview:

| Expense Item | Estimated Cost |

|---|---|

| Controller Board | $100 – $300 |

| Cables and Connectors | $20 – $50 |

| Sensors | $30 – $100 |

| Total for Conversion | $150 – $450 |

In comparison, a new CNC lathe can cost thousands! So, why not give your old lathe a modern twist? It’s cost-effective and pretty fun!

Best Practices for Maintaining Your CNC Lathe

Regular maintenance tips specific to upgraded lathe systems. Importance of software updates and hardware checks.To keep your CNC lathe in top shape, regular care is key. Check parts often for wear. Clean the machine regularly to avoid dust buildup. Make sure to update your software for improved performance. Don’t forget to inspect all hardware for any loose connections. Here are some simple tips:

- Lubricate moving parts regularly.

- Calibrate settings after upgrades.

- Replace worn components quickly.

Staying on top of these tasks helps your lathe run smoothly and last longer. It prevents issues and keeps your work accurate.

Why is regular software updating important?

Updating software fixes bugs and adds new features. It makes your lathe more efficient and safe to use. Regular updates help avoid machine failures too.

Real-World Examples of Successful Lathe Conversions

Case studies showcasing various projects. Lessons learned and key takeaways from experienced users.Many DIY enthusiasts share stories of their lathe conversion projects. One user turned a rusty old lathe into a modern tool, learning that patience is key. Another discovered that a little creativity can solve big problems. The important lesson? Mistakes happen, and they often lead to great ideas! Below is a table showing various projects and the lessons learned from them:

| Project | Key Takeaway |

|---|---|

| Old Lathe Restoration | Patience pays off! |

| Custom Controller Setup | Think outside the box! |

| Speed Upgrade | Don’t rush, double-check! |

Users found that sharing experiences helps others. It’s like a big, nerdy support group for lathe lovers! So, if you think your lathe isn’t worth it, remember: every great tool starts with a little love and a lot of tinkering.

Resources for Further Learning

Recommended books, websites, and forums. Online communities for advice and support.Want to explore more about lathe conversion? Here are some great resources:

- Books: Look for books on CNC lathes at your library or bookstore. They can give you hands-on projects.

- Websites: Visit sites like Instructables or WikiHow for tutorials.

- Forums: Join online forums like Reddit’s CNC community for tips and advice.

- Online Communities: Check out Facebook groups dedicated to machining and lathes. They can offer support and friendship.

These places are great for learning and connecting. Start your journey today!

Where can I find helpful videos on lathe conversion?

YouTube is a fantastic resource. Search for lathe conversion tutorials. Many experts share tips and tricks there.

Conclusion

In conclusion, a lathe conversion metal lathe controller board upgrades your machine for better control. It enhances precision and efficiency. You can transform your manual lathe into a CNC machine. This opens new possibilities for your projects. We encourage you to explore more about these controllers and consider trying a conversion. Learning more can lead to exciting new skills!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Conversion And Metal Lathe Controller Boards:A lathe is a machine that helps shape metal or wood. When we talk about lathe conversion, we mean changing a regular lathe to a better one. Metal lathe controller boards are like the brains of the lathe. They help control how fast it spins and what it does. If you want to upgrade your lathe, these boards can make it easier and more fun to use!

Sure! Please provide the specific question you’d like me to answer.

What Are The Essential Components Needed For Converting A Manual Lathe Into A Cnc (Computer Numerical Control) Lathe?To change a manual lathe into a CNC lathe, you need a few important parts. First, you need a computer that can control the lathe. Next, you’ll need motors to move the tools and the workpiece. You also need a controller that connects the computer and motors. Lastly, don’t forget software that helps you design and control the cuts. With these parts, you can make precise shapes!

How Do Different Types Of Controller Boards (Such As Arduino, Grbl, Or Machcompare For Use In Lathe Conversions?Different controller boards help us control machines like lathes. Arduino is a simple board that you can use to create your own projects. GRBL is software that runs on Arduino, making it easier to move the machine smoothly. Mach3 is another popular option that works on computers. Each one has different features, so you can choose based on what you need for your lathe.

What Factors Should Be Considered When Choosing A Stepper Motor Or Servo Motor For My Lathe Conversion Project?When choosing a stepper motor or servo motor for your lathe, think about how much power you need. You should also consider how precise you want your machine to be. Check your budget because some motors are more expensive than others. Finally, look at how easily you can control the motor with your tools. These factors will help you pick the right motor for your project!

How Can I Interface Limit Switches And Other Safety Features With A Lathe Controller Board?To connect limit switches and safety features to a lathe controller board, you start by checking the board’s manual. This will show you where to connect the wires from the switches. You can use simple wires to link the switches to the board. Limit switches help stop the lathe if it goes too far. Always make sure to test everything before you use it, so you stay safe!

What Software Options Are Available For Programming And Controlling A Converted Metal Lathe, And How Do They Differ In Functionality?You can use different programs to control a metal lathe. Some popular options are Mach3, LinuxCNC, and GRBL. Mach3 is easy to use and great for beginners. LinuxCNC is more advanced and good for serious projects. GRBL works well on small machines and is free. Each program has unique features, so you can pick one that fits your needs!