Have you ever wondered how a simple machine can create amazing things? A lathe is one of those machines. It spins materials like wood or metal to shape them into useful tools or beautiful pieces. But did you know you can turn an old lathe into a powerful metal lathe? That’s where lathe conversion comes in. It allows you to take an old machine and upgrade it.

Wiring is a big part of this upgrade. Understanding the lathe wiring diagram can feel tough, but it’s like following a treasure map. Each wire connects parts to create magic! Imagine taking something old and making it even better.

This article will show you how to look at wiring diagrams. It will help you understand the process of converting a lathe into a metal lathe. With the right knowledge, you can handle this project like a pro. Are you ready to dive into the world of lathes?

Lathe Conversion: Metal Lathe Wiring Diagram Explained

Understanding Lathe Conversion Metal Lathe Wiring Diagram

Lathe conversion involves transforming a basic lathe into a metal lathe. A metal lathe wiring diagram helps users connect motors and controls correctly. Knowing how to wire your lathe can boost performance and safety. Did you know that a simple wiring mistake can lead to costly repairs? By following a clear diagram, you can avoid these issues and ensure smooth operation. Don’t underestimate the power of proper wiring! It’s key to achieving great results in your machining projects.Understanding Lathe Conversion

Definition and importance of lathe conversion. Benefits of converting traditional lathes to CNC.Lathe conversion is like giving your old friend a new pair of shoes. It upgrades a traditional lathe into a CNC machine, making it smarter and faster. Why bother? Well, converting traditional lathes to CNC can save time and improve accuracy! And let’s be honest, who wouldn’t want a machine that can do the hard work while you snack on cookies? The benefits are clear. Let’s break them down:

| Benefit | Description |

|---|---|

| Increased Efficiency | Speed up production like a race car! |

| Improved Precision | Make those cuts sharper than your dad’s jokes! |

| Ease of Use | Less fuss, more fun! |

In short, lathe conversion makes machining a breeze, and who wouldn’t want to work smarter, not harder?

Creating a Metal Lathe Wiring Diagram

Stepbystep guide for designing a wiring diagram. Importance of labeling and organizing connections.Designing a wiring diagram is an important step in converting a metal lathe. Here’s a simple guide to help you.

- Start by sketching the layout.

- Identify all parts like the motor and switch.

- Draw lines to show connections.

- Use different colors for clarity.

- Label each connection clearly.

Why is labeling important in wiring diagrams?

Labeling ensures everyone understands the connections. It also saves time during repairs. A well-organized diagram keeps your project running smoothly. Remember, clear labels can prevent confusion.

Wiring Diagrams Explained

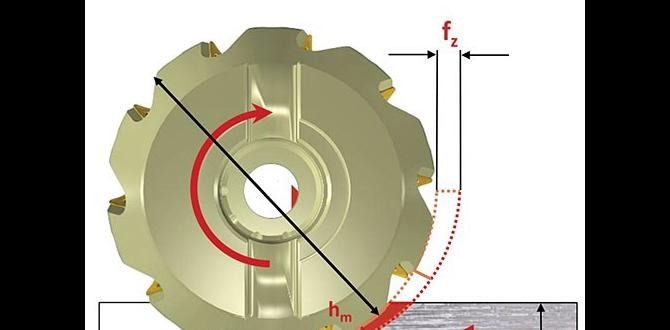

Breakdown of different wiring configurations. Understanding the role of power supply and motor connections.Wiring diagrams help you understand how to connect your lathe properly. Let’s break down the key parts:

- Power Supply: This gives the energy to run your lathe.

- Motor Connections: This links the motor to the power supply, enabling movement.

Using a wiring diagram will show you different configurations. Each setup can affect how the lathe operates. Knowing these details ensures your lathe works efficiently and safely.

What is the importance of understanding wiring diagrams?

Understanding wiring diagrams is essential for safe and effective lathe operation. They prevent mistakes that could damage your equipment or cause accidents.

Key Aspects of Wiring Diagrams:

- Clear layout of connections

- Identification of components

- Basic troubleshooting guide

Safety Precautions During Conversion

Common safety hazards associated with lathe conversion. Recommended safety gear and practices.Working with lathes can be fun, but safety is a must! Common hazards include flying debris, sharp tools, and electrical shock. To stay safe during lathe conversion, wear protective gear and follow these practices:

- Always wear safety glasses to protect your eyes.

- Use ear protection to guard against loud noise.

- Wear gloves to avoid cuts, but remove them when working near moving parts.

- Keep the area clean and free of clutter.

- Ensure that all guards and safety devices are in place before starting.

What are the safety hazards of lathe conversion?

Common hazards include sharp edges, spinning parts, and electrical risks. Always be careful and stay alert!

Troubleshooting Common Wiring Issues

Identifying common problems in wiring setups. Tips for effective troubleshooting and solutions.Wiring problems can cause headaches for anyone. Look for these common issues: frayed wires, loose connections, or incorrect colors. These problems can mess up your machine. To fix issues easily, follow these steps:

- Check all connections to ensure they are tight.

- Inspect wires for damage or wear.

- Use a multimeter to test for power.

- Refer to your lathe conversion metal lathe wiring diagram for guidance.

Don’t let wiring issues stop you! With some patience, you can get everything running smoothly again.

What are the signs of wiring problems?

Watch for sparking, burning smell, or equipment not working. These signs often mean something is wrong with the wiring.

How can I resolve wiring issues quickly?

- Start with the simplest fixes first.

- Consult manuals or guides for advice.

Case Studies: Successful Lathe Conversions

Examples of successful lathe conversion projects. Lessons learned from each case.Many people have turned old machines into useful tools with successful lathe conversions. Here are some inspiring examples:

- Vintage Lathe to CNC: A user upgraded a manual lathe to a CNC machine. This allowed for more precise cuts and designs.

- Small Lathe Transformation: Someone changed a mini-lathe into a powerful, versatile tool, making small projects easier.

- DIY Electric Conversion: A user added a new motor to a classic lathe. This boosted its efficiency, making the machine run smoother.

From these projects, many lessons emerged:

- Research is vital for successful upgrades.

- Quality materials make a big difference.

- Patience helps in learning new skills.

Resources for Further Learning

Recommended books, websites, and forums. Community resources and networking opportunities.Learning about lathe conversion can be extra fun with the right resources! There are books like “*Lathe Workshop*” that break down complex ideas into simple steps. Websites such as lathes.co.uk offer tons of diagrams, including helpful metal lathe wiring diagrams. Don’t forget to check out forums like Reddit’s r/metalworking for real-life tips from users who have “been there, done that”. Connecting with others in your community can also provide valuable advice and support. Networking with local clubs can turn your projects into epic tales of creativity!

| Resource Type | Name | Link |

|---|---|---|

| Book | Lathe Workshop | Available at bookstores |

| Website | Lathes UK | lathes.co.uk |

| Forum | Reddit r/metalworking | reddit.com/r/metalworking |

| Networking | Local Maker Clubs | Search in your area! |

Conclusion

In summary, a lathe conversion wiring diagram helps you understand how to set up your metal lathe. It guides you through essential connections and safety tips. You can improve your skills by practicing with the diagram and exploring online resources. Remember, clear wiring is critical for safe and efficient work. Dive into your project and enjoy learning more!FAQs

What Are The Essential Components Needed For Converting A Metal Lathe To A Different Power Source, And How Should They Be Wired Together In The Diagram?To change a metal lathe’s power source, you need a new motor, a switch, and wires. First, connect the motor to the power supply. Then, attach the switch in between, so you can turn the lathe on and off. Make sure all wires are secure and follow the instructions carefully. Don’t forget to double-check your connections before powering it up!

How Can I Create A Wiring Diagram For A Variable Speed Control System On My Metal Lathe?To create a wiring diagram for your metal lathe’s speed control, start by drawing the parts. You’ll need the motor, speed controller, and power source. Connect them with lines to show the wiring. Make sure to label each part clearly so you know what it is. Finally, double-check your drawing to ensure everything matches how the parts connect.

What Safety Precautions Should I Consider When Wiring A Converted Metal Lathe For A New Motor?When wiring your metal lathe, safety is important. First, always unplug the lathe before you start working. Use safety goggles to protect your eyes from sparks. Make sure your workspace is clean and dry to avoid slips. Lastly, double-check your connections to prevent any short circuits.

Are There Any Specific Wiring Diagrams Available For Popular Metal Lathe Models, And Where Can I Find Them?Yes, there are wiring diagrams for popular metal lathe models. You can usually find them in the user manuals. Websites like the manufacturer’s site or hobbyist forums also share these diagrams. If you’re having trouble, you can ask someone who knows more about lathes to help.

How Can I Troubleshoot Common Wiring Issues That May Arise After Converting A Metal Lathe?To troubleshoot wiring issues after converting a metal lathe, start by checking all connections. Make sure wires are tight and not damaged. Next, look for any frayed or broken wires that might need fixing. You can also use a multimeter, a tool that checks electricity, to find any problems. If something doesn’t work, ask for help or check the manual.