Have you ever wondered how machines like lathes work? They need different parts to move smoothly and accurately. One important part is the cross slide. This piece helps control the tool’s movements. Sometimes, the cross slide needs attention, and that means disassembling it. But how do you do that safely and easily?

In this article, we’ll explore the lathe cross slide disassembly steps together. Imagine taking apart a puzzle to see how each piece fits. With the right steps, you can master this task! It might seem tricky, but we’ll break it down into simple actions.

Taking a part apart can be fun and rewarding. Did you know that many hobbyists find joy in fixing their lathes? They feel proud once they complete the job. Are you ready to learn something new? Let’s dive into the disassembly process and make your lathe work better!

Lathe Cross Slide Disassembly Steps: A Complete Guide

Lathe Cross Slide Disassembly Steps

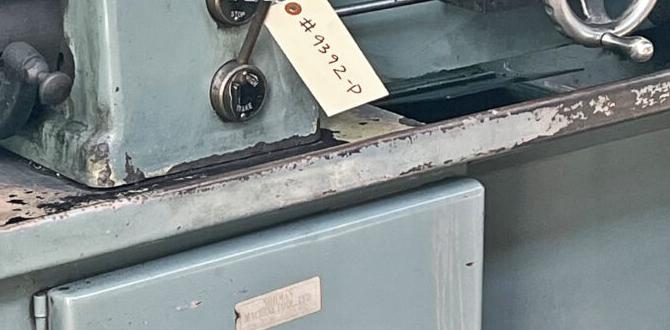

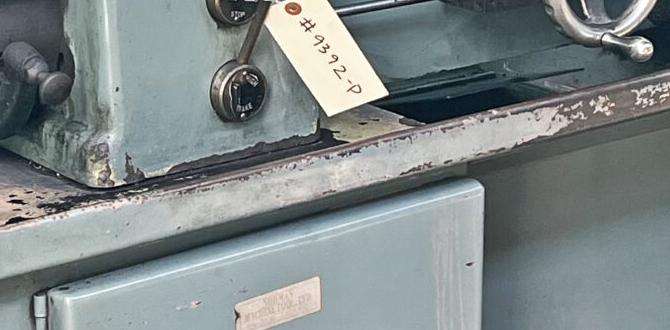

Disassembling a lathe cross slide can seem tricky, but it’s often simpler than you think. First, ensure the lathe is turned off and unplugged. Remove any bolts that secure the cross slide in place. Next, pay close attention to the way parts fit together. Taking pictures during disassembly helps with reassembly later. Did you know that proper cleaning during this process can prolong your lathe’s life? Following these steps carefully ensures effective maintenance for your machine.Tools Required for Disassembly

List of essential tools for safe and effective disassembly.. Safety gear and precautions to consider during the process..To take apart a lathe cross slide safely, gather these tools:

- Wrenches for loosening bolts

- Screwdrivers for removing screws

- Pliers for gripping parts

- Safety glasses to protect eyes

- Work gloves to keep hands safe

Before starting, remember to follow safety measures. Wear your safety gear to avoid accidents. Keep your workspace tidy and free of distractions. Being prepared can make disassembly easier.

What tools do you need for disassembly?

You need wrenches, screwdrivers, pliers, safety glasses, and work gloves.Preparation for Disassembly

Steps to ensure the lathe is properly powered down and secured.. Assessing the condition of the cross slide before starting..Before diving into the lathe cross slide disassembly, make sure your lathe is powered down. Double-check that it’s not plugged in. Safety first, right? Then, take a close look at your cross slide. Is it stuck? Any odd sounds? Treat it like a car; you wouldn’t start disassembling it without a quick vehicle check!

| Preparation Step | Description |

|---|---|

| Power Down | Turn off the lathe and disconnect it from the power source. |

| Inspect Cross Slide | Look for damage or wear before starting the disassembly. |

With these steps, you’re setting yourself up for success. Just like baking, preparation is key! Happy disassembling!

Step-by-Step Disassembly Process

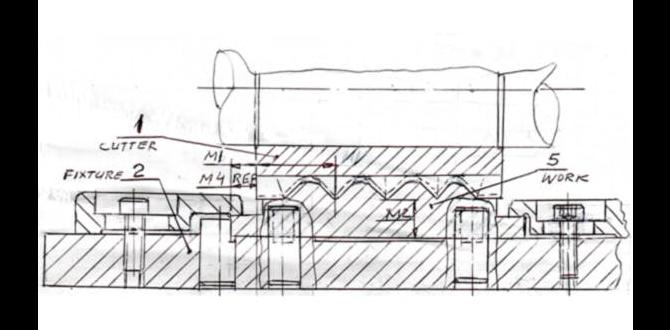

Detailed instructions for removing the cross slide from the lathe bed.. Explanation of each component involved in the disassembly..Disassembling the cross slide from your lathe bed is a breeze! Start by gathering your tools. You’ll need a wrench and a screwdriver. Loosen the screws on the cross slide with the wrench. Don’t worry, it’s not the ‘Twilight Zone’—nothing will jump out at you! Next, gently lift the cross slide away from the bed. It has a few parts, like the saddle and carriage, that help it move smoothly. Here’s a tiny table to keep things neat:

| Part | Description |

|---|---|

| Saddle | Supports the cross slide, making it slide nice and easy. |

| Carriage | Helps move the cutting tool back and forth. |

With a little patience, you’ll have it all apart in no time. Just remember, if it doesn’t move, don’t force it—give it a gentle nudge instead!

Common Issues to Look For During Disassembly

Identification of wear and tear in components.. Signs of lubrication failure or damage that may affect performance..During disassembly, it’s important to watch for some key issues. Look closely at each part for wear and tear. You might see scratches or rough spots. These can make the machine run poorly. Check the lubrication system too. Signs of lubrication failure include dirt buildup or sticky surfaces. These issues can affect the performance of the lathe. Here are some signs to notice:

- Rust or corrosion on parts

- Odd noises when moving components

- Difficulty moving the cross slide

What are signs of wear and lubrication failure?

Common signs include scratches, noise, and rust. These may indicate worn-out parts or poor lubrication, which affects the lathe’s performance.

Reassembly Tips and Best Practices

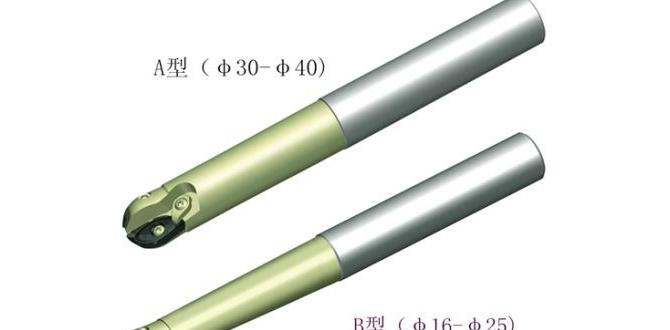

Guidance on reattaching components correctly.. Recommendations for lubrication and maintenance checks..Put the pieces back together carefully. Make sure you align the components correctly. This helps them work well. Always check for wear and tears in parts. Clean them before fixing everything back. Use grease or oil on moving parts. This keeps things smooth and safe. Regular checks can prevent problems. Here are some quick tips:

- Align parts properly before tightening.

- Lubricate important areas to reduce friction.

- Check screws and bolts for tightness.

- Keep tools handy for quick repairs.

What is the best way to lubricate a lathe cross slide?

Use lightweight oil or grease on sliding surfaces. Apply it evenly to ensure smooth movement.

Troubleshooting After Reassembly

Common problems to watch for once the cross slide is reassembled.. How to diagnose and fix issues that may arise from improper disassembly..After putting everything back together, you might find a few hiccups. One common issue is the cross slide sticking. This can happen when parts are misaligned, like a puzzle piece that just won’t fit! To fix it, simply check for any loose screws or bent components. Another problem could be strange noises. If you hear weird sounds, it might mean something isn’t lubricated enough. Make sure to apply grease where needed. Want to keep track of these troubleshooting steps? Here’s a handy table:

| Problem | Solution |

|---|---|

| Cross Slide Sticking | Check alignment and tighten screws. |

| Unusual Noises | Lubricate moving parts properly. |

Remember, it’s all about the little details. If something sounds off, don’t ignore it! Diagnosing these issues quickly can save you from a bigger headache later on.

Conclusion

In conclusion, disassembling the lathe cross slide involves careful steps. First, gather your tools. Next, remove screws and lift off parts gently. Remember to take notes or pictures for reassembly. Always prioritize safety. You’ve learned the basic steps, so practice them on your lathe. For more tips and tricks, check out other resources or guides!FAQs

What Tools Are Required For Safely Disassembling The Cross Slide Of A Lathe?To safely take apart the cross slide of a lathe, you need a few tools. First, use a socket wrench to remove bolts. Next, have a screwdriver ready for screws. A soft cloth can help protect the parts. Finally, wear safety glasses to protect your eyes.

What Are The Common Signs That Indicate It’S Time To Disassemble The Cross Slide For Maintenance?You might need to take apart the cross slide for maintenance if you notice some problems. If it feels sticky or hard to move, that’s a sign. You might also see rust or dirt on the parts. If you hear weird noises when using it, pay attention to that too. These signs mean it’s time for a check-up!

What Specific Steps Should Be Followed To Remove The Cross Slide From The Lathe Carriage?To remove the cross slide from the lathe carriage, first turn off the machine and unplug it for safety. Next, use a wrench to loosen the bolts that hold the cross slide in place. After that, carefully slide the cross slide off the carriage. Finally, keep all the bolts in a safe place so you can find them later.

How Can I Ensure That All Components Of The Cross Slide Are Properly Cleaned And Inspected During Disassembly?To clean and inspect the cross slide parts, start by wiping each piece with a cloth. Check for dirt, scratches, or cracks while you clean. Use a small brush to get into tight spaces. Remember to keep all parts organized so they don’t get mixed up. Finally, look at each piece closely to make sure they are in good condition before putting them back together.

What Precautions Should I Take To Avoid Damaging The Cross Slide Or Other Parts During The Disassembly Process?To avoid damaging the cross slide and other parts, be gentle when you unscrew or pull things apart. Use the right tools for each part. Keep small items, like screws, in a safe place so they don’t get lost. Stay organized and work slowly to prevent mistakes. If something feels stuck, don’t force it!

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “What Tools Are Required For Safely Disassembling The Cross Slide Of A Lathe? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To safely take apart the cross slide of a lathe, you need a few tools. First, use a socket wrench to remove bolts. Next, have a screwdriver ready for screws. A soft cloth can help protect the parts. Finally, wear safety glasses to protect your eyes.”}},{“@type”: “Question”,”name”: “What Are The Common Signs That Indicate It’S Time To Disassemble The Cross Slide For Maintenance? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “You might need to take apart the cross slide for maintenance if you notice some problems. If it feels sticky or hard to move, that’s a sign. You might also see rust or dirt on the parts. If you hear weird noises when using it, pay attention to that too. These signs mean it’s time for a check-up!”}},{“@type”: “Question”,”name”: “What Specific Steps Should Be Followed To Remove The Cross Slide From The Lathe Carriage? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To remove the cross slide from the lathe carriage, first turn off the machine and unplug it for safety. Next, use a wrench to loosen the bolts that hold the cross slide in place. After that, carefully slide the cross slide off the carriage. Finally, keep all the bolts in a safe place so you can find them later.”}},{“@type”: “Question”,”name”: “How Can I Ensure That All Components Of The Cross Slide Are Properly Cleaned And Inspected During Disassembly? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To clean and inspect the cross slide parts, start by wiping each piece with a cloth. Check for dirt, scratches, or cracks while you clean. Use a small brush to get into tight spaces. Remember to keep all parts organized so they don’t get mixed up. Finally, look at each piece closely to make sure they are in good condition before putting them back together.”}},{“@type”: “Question”,”name”: “What Precautions Should I Take To Avoid Damaging The Cross Slide Or Other Parts During The Disassembly Process? “,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To avoid damaging the cross slide and other parts, be gentle when you unscrew or pull things apart. Use the right tools for each part. Keep small items, like screws, in a safe place so they don’t get lost. Stay organized and work slowly to prevent mistakes. If something feels stuck, don’t force it!”}}]}