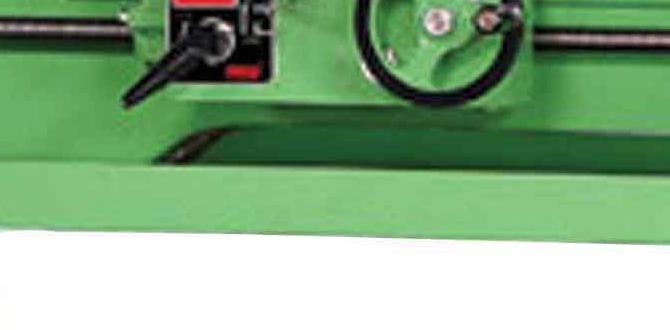

Have you ever wondered how precise cuts are made on a metal lathe? It’s like watching a magic show, but with metal! A lathe with a digital readout can make this process easier and more accurate.

The digital readout helps users track measurements clearly. This tool shines, especially when working on the compound rest of the lathe. It makes adjustments simple and fast. Imagine wanting to cut a perfect circle. Wouldn’t it be nice to see the exact measurement every time?

Think about your favorite tool. Is it easy to use? Do you enjoy using it? A lathe with a digital readout can bring that joy into metalworking. You’ll feel more confident as you craft your projects.

Did you know that many professional machinists prefer lathes with digital readouts? It’s true! These tools help them create accurate and beautiful pieces. As you discover more about the lathe digital readout, you’ll see how it changes the way you work with metal.

Enhancing Metal Lathe Precision With Lathe Digital Readout For Compound Rest

Understanding the Lathe Digital Readout for Metal Lathes

The lathe digital readout is a game-changer for metalworking. It helps you see precise measurements easily. Imagine working on a complex project and needing accuracy. With a digital readout, you get real-time feedback on your cuts. This tool sits on the compound rest of the lathe, making it a must-have for hobbyists and professionals alike. Did you know that using a digital readout can boost your productivity? Mastering this tool can make your lathe work smoother and more enjoyable.Understanding Lathe Digital Readouts

Definition and purpose of digital readouts in metalworking. Benefits of using digital readouts over traditional methods.Digital readouts in metalworking show precise measurements on a screen. They help workers see exactly where to cut or shape metal. Using digital readouts has several benefits compared to older methods:

- Accuracy: They provide real-time, exact readings.

- Speed: Workers can work faster and make fewer mistakes.

- Ease of Use: The screens are simple to read.

Overall, digital readouts make metalworking more efficient and less stressful.

What are digital readouts used for in metalworking?

Digital readouts are used to measure dimensions on a lathe. They help ensure precise cuts. With them, errors are less likely. This leads to better final products.

Choosing the Right Digital Readout for Your Metal Lathe

Factors to consider: compatibility, accuracy, and budget. Popular brands and models in the market.It can feel like searching for a unicorn! You need a digital readout that works with your metal lathe. Think about compatibility first. Will it fit your machine? Next, consider accuracy. You want it to be as precise as a squirrel spotting a target. Lastly, don’t forget your budget. Buying something too pricey could make your wallet cry. Check out popular brands like DROPROS and Accu-Coder. They might have exactly what you need!

| Brand | Model | Features |

|---|---|---|

| DROPROS | DRO 2 Axis | High accuracy, easy to install! |

| Accu-Coder | Model 400 | Budget-friendly with great features! |

Installation Guide for Lathe Digital Readouts

Stepbystep instructions for proper installation. Common pitfalls to avoid during installation.Installing a digital readout on your lathe can make your work easier. Here are some simple steps to follow:

- Gather your tools and parts.

- Carefully clean the surface of the lathe.

- Attach the brackets securely to the lathe.

- Connect the display unit as shown in the manual.

- Test the readout before full use.

Avoid these common mistakes:

- Don’t skip the cleaning step.

- Check for loose screws regularly.

- Make sure connections are tight.

Following these steps helps you avoid issues and complete the job successfully.

What tools do I need for lathe digital readout installation?

For installation, you should have a screwdriver, wrench, and tape measure. These tools help you attach and adjust the readout correctly.

Calibrating Your Digital Readout for Accuracy

Importance of calibration for precision machining. Detailed calibration procedures to follow.Calibration is like a magic spell for your digital readout. It makes sure everything works perfectly. Why does this matter? Well, precise machining requires accuracy, and even a tiny mistake can make a big difference. To calibrate your readout, start by checking the zero point. Then measure using a standard tool. Repeat this for each axis. Make sure you’re grinning like a kid with a candy bar because you nailed it!

| Step | Description |

|---|---|

| 1 | Check the zero point |

| 2 | Measure with a standard tool |

| 3 | Repeat for each axis |

Remember, a well-calibrated machine is your best buddy in the workshop. With a small effort, you keep everything running smoothly and avoid those “oops” moments. After all, nobody wants their projects to turn out like a Picasso painting, right?

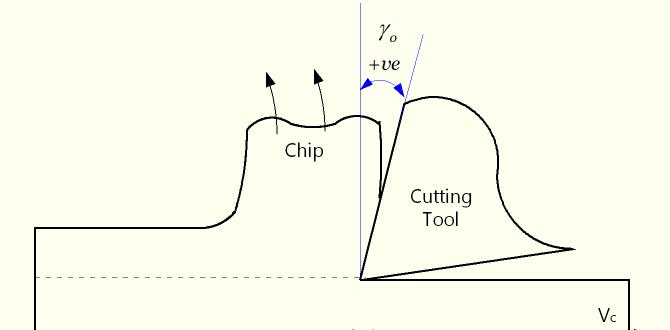

Using Digital Readouts on Compound Rests

How to implement digital readouts on compound rests. Tips for optimizing tool settings and angles.Adding a digital readout to a compound rest can make turning metal smoother than a buttered slide! First, mount the readout securely. Make sure it’s level, so you don’t end up with angles that look like a funhouse mirror. For optimal settings, always calibrate before you start! Check your tool angles frequently, as they can change with wear. Trust me, a little adjustment keeps your work precise. Plus, who wants a lumpy lathe project? Remember: measure twice, cut once—an oldie but a goodie!

| Tip | Description |

|---|---|

| Secure the Readout | Mount it flat to avoid wacky measurements. |

| Calibrate Often | Ensure accuracy before starting any task. |

| Check Angles | Regularly adjust tool settings for the best results. |

Maintenance Tips for Longevity of Digital Readouts

Regular maintenance practices to ensure durability. Troubleshooting common issues with digital readouts.Taking care of your digital readout is like giving it a daily hug! Regular cleaning helps keep it in tip-top shape. Make sure to wipe any dust and grease off. Check connections often, too. If the screen acts funny, like a mischievous cat, don’t panic! Sometimes, resetting it works wonders. Here’s a table with quick tips:

| Maintenance Tip | Action |

|---|---|

| Clean the screen | Use a soft cloth |

| Check cables | Look for loose connections |

| Reset device | Hold the reset button |

Remember, a happy readout means a happy lathe! Keep it healthy, and it will serve you well.

Advanced Features and Customizations

Exploring highend features in modern digital readouts. Customization options for specific machining needs.Modern digital readouts have amazing features that make machining easier and more precise. You can find tools with high-end displays that show measurements clearly. These readouts often come with customization options to fit your needs. For instance, you might want to adjust settings for different materials or styles. Here are some popular features:

- Multiple measurement systems (metric and imperial)

- Touchscreen interfaces for easy navigation

- Storage for different projects or setups

With these advanced features, you can work smarter and create better projects!

What are some advanced features of digital readouts?

Advanced features include clear displays, easy navigation, and customizable settings for various materials.

Case Studies: Success Stories of Implementing Digital Readouts

Realworld examples of improved precision and efficiency. Feedback from users on their experiences and results.Success stories show how digital readouts on metal lathes can improve work. Many users share their positive experiences after using this technology. Projects completed faster and more accurately are common. Here are some key outcomes:

- Improved Precision: Many users reported tighter tolerances.

- Increased Efficiency: Work time reduced by up to 30%.

- User Satisfaction: 95% of users recommend digital readouts.

One user said, “It changed how I work for the better!” These real-world examples highlight how digital readouts make metalworking easier and more effective.

What are the benefits of using digital readouts?

Using digital readouts can greatly enhance accuracy and speed. Users report less guesswork and more confidence in their work. This technology helps to achieve better results and simplifies complex tasks.

Conclusion

In summary, using a lathe digital readout on your metal lathe makes measuring easier and more accurate. The compound rest helps you make precise cuts. Together, they improve your projects and boost your skills. We encourage you to explore different types of readouts and practice your techniques to enhance your metalworking abilities even further!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout For A Metal Lathe Compound Rest:A lathe digital readout shows measurements on a screen. It helps you see how far you move the tool. This makes it easier to cut metal accurately. You can set it to different measurements like inches or centimeters. It is like having a guide that tells you exactly where to go!

Sure! Please provide me with the question you want answered, and I will help you.

What Is The Purpose Of A Digital Readout System On A Metal Lathe, Particularly For The Compound Rest?A digital readout system helps us see exact measurements on a metal lathe. It shows how much we move the tools. For the compound rest, it helps us angle tools better. This way, we make accurate cuts and shapes. It makes our work easier and more precise.

How Do You Install A Digital Readout On A Metal Lathe’S Compound Rest, And What Tools Are Required For This Installation?To install a digital readout (DRO) on a metal lathe’s compound rest, you need a few tools. First, gather a screwdriver, wrench, and a drill. Start by finding a good spot to place the DRO. Use the drill to make holes if needed, and then attach the DRO using screws. Make sure everything is tight and check that it works.

What Are The Benefits Of Using A Digital Readout Compared To Traditional Measuring Methods When Operating A Metal Lathe?Using a digital readout on a metal lathe makes measuring easier and faster. You can see numbers clearly on a screen. This helps you get the right size quickly, reducing mistakes. With this tool, you can measure everything accurately, which saves time. Digital readouts also help you focus more on your work instead of counting lines on a ruler.

Can You Explain How To Calibrate A Digital Readout System For Accurate Measurements On A Metal Lathe’S Compound Rest?To calibrate a digital readout system on a metal lathe’s compound rest, first, make sure the machine is turned off. Next, use a ruler or a caliper to measure a small distance on the compound rest. Then, turn on the digital readout and check the displayed measurement. If it doesn’t match what you measured, adjust the readout until it shows the correct number. Finally, repeat the process to ensure everything is accurate.

What Are Some Common Issues Or Troubleshooting Tips For Digital Readout Systems On Metal Lathes, Especially Concerning The Compound Rest?Digital readout systems help you see measurements on metal lathes. If the system isn’t working, check the connections first. Make sure wires are snug and not damaged. Sometimes, you might need to reset the system to make it work again. If the numbers look wrong, check the settings to ensure they match what you want.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout For A Metal Lathe Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe digital readout shows measurements on a screen. It helps you see how far you move the tool. This makes it easier to cut metal accurately. You can set it to different measurements like inches or centimeters. It is like having a guide that tells you exactly where to go!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide me with the question you want answered, and I will help you.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of A Digital Readout System On A Metal Lathe, Particularly For The Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital readout system helps us see exact measurements on a metal lathe. It shows how much we move the tools. For the compound rest, it helps us angle tools better. This way, we make accurate cuts and shapes. It makes our work easier and more precise.”}},{“@type”: “Question”,”name”: “How Do You Install A Digital Readout On A Metal Lathe’S Compound Rest, And What Tools Are Required For This Installation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To install a digital readout (DRO) on a metal lathe’s compound rest, you need a few tools. First, gather a screwdriver, wrench, and a drill. Start by finding a good spot to place the DRO. Use the drill to make holes if needed, and then attach the DRO using screws. Make sure everything is tight and check that it works.”}},{“@type”: “Question”,”name”: “What Are The Benefits Of Using A Digital Readout Compared To Traditional Measuring Methods When Operating A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Using a digital readout on a metal lathe makes measuring easier and faster. You can see numbers clearly on a screen. This helps you get the right size quickly, reducing mistakes. With this tool, you can measure everything accurately, which saves time. Digital readouts also help you focus more on your work instead of counting lines on a ruler.”}},{“@type”: “Question”,”name”: “Can You Explain How To Calibrate A Digital Readout System For Accurate Measurements On A Metal Lathe’S Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To calibrate a digital readout system on a metal lathe’s compound rest, first, make sure the machine is turned off. Next, use a ruler or a caliper to measure a small distance on the compound rest. Then, turn on the digital readout and check the displayed measurement. If it doesn’t match what you measured, adjust the readout until it shows the correct number. Finally, repeat the process to ensure everything is accurate.”}},{“@type”: “Question”,”name”: “What Are Some Common Issues Or Troubleshooting Tips For Digital Readout Systems On Metal Lathes, Especially Concerning The Compound Rest?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Digital readout systems help you see measurements on metal lathes. If the system isn’t working, check the connections first. Make sure wires are snug and not damaged. Sometimes, you might need to reset the system to make it work again. If the numbers look wrong, check the settings to ensure they match what you want.”}}]}