Have you ever wondered how metal parts are made so precisely? A lathe plays a big role in this process. With a lathe, you can shape metal into all sorts of items. But there’s something that can make this task even easier: a lathe digital readout.

A lathe digital readout shows you clear measurements while you work. This means less guessing and better results. Imagine building something amazing and knowing exactly how it will turn out! Sounds fun, right?

Now, let’s talk about what makes a lathe digital readout even better. A metal lathe controller board works with it to give you more control. This board can help you plan and execute your projects with ease. With these tools, your creative dreams can come true.

In this article, you’ll learn how to choose and use these tools effectively. Get ready to dive into the fascinating world of metalworking!

Lathe Digital Readout: Metal Lathe Controller Board Insights

Understanding Lathe Digital Readouts

A lathe digital readout can transform your metalworking experience. This device helps you see precise measurements easily. Have you ever tried to guess how deep a cut is? With a digital readout, you won’t have to! A good controller board brings convenience. It makes operating the lathe simpler and more accurate. Imagine saying goodbye to tedious calculations! This upgrade can lead to better results and saves time. It’s like having a helpful assistant right by your side. Why not explore this technology today?Understanding Digital Readouts in Metal Lathes

Definition and purpose of digital readouts. Benefits of using digital readouts in metal lathes.Digital readouts are nifty tools found on metal lathes. They show exact measurements on a clear screen. This helps workers see how much they cut or move their machines. The benefits of using digital readouts include:

- Improved accuracy in measurements

- Faster setup times

- Less chance of mistakes

With these features, operators can work confidently and efficiently.

What are the advantages of digital readouts in metal lathes?

The advantages of digital readouts include better precision, time savings, and reduced errors. They make tasks easier for everyone!

Key Features to Look for in a Controller Board

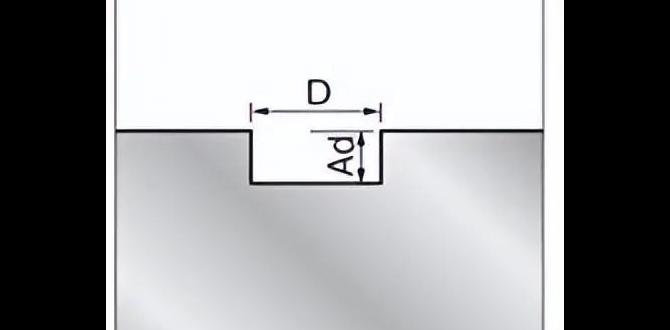

Essential features for efficient operation. Importance of accuracy and resolution.Choosing the right controller board can make or break your metal lathe experience. First, look for high accuracy and resolution—nobody wants to end up with wobbly wheels on a bicycle! A good board helps you make precise cuts every time. Also, features like user-friendly displays and quick response times keep your work moving at a good pace. Think of it as a GPS; you want it to guide you accurately without rerouting you to some random place!

| Feature | Why It Matters |

|---|---|

| Accuracy | Ensures exact cuts |

| Resolution | Improves detail quality |

| User-friendly display | Simplifies operation |

| Quick response time | Speeds up workflow |

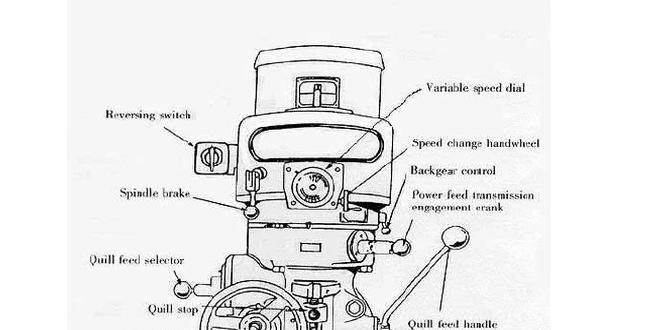

Installing a Digital Readout on a Metal Lathe

Stepbystep installation process. Common pitfalls and how to avoid them.Installing a digital readout on your metal lathe can improve your work greatly. Here’s a simple step-by-step process:

- First, gather all necessary tools and parts.

- Next, carefully mount the display unit on the lathe’s front.

- Connect the sensors to the lathe’s axis.

- Finally, power up and calibrate the system.

Watch for common mistakes, like loose wires or incorrect settings. Always double-check your connections. This helps avoid big problems. By following these steps, you will enjoy easy and accurate measurements with your lathe.

What are some tips for avoiding pitfalls during installation?

Some tips include ensuring all components are compatible, keeping the workspace clean, and referring to the manual. Take your time to avoid mistakes. Slow and steady wins the race!

Popular Lathe Digital Readout Models

Review of top models available on the market. User feedback and performance analysis.Many models of lathe digital readouts are popular among users. They help with precision in metalworking. Here are some top choices:

- Model A: Offers great accuracy and speed. Users love its easy setup.

- Model B: Known for a user-friendly interface. Customers say it helps them work faster.

- Model C: Durable and reliable for daily tasks. Feedback shows high satisfaction rates.

Most users report smoother operations with these models. They also appreciate the added accuracy in their projects. Overall, these lathe digital readouts deliver strong performance.

What makes a good lathe digital readout?

A good lathe digital readout offers accuracy, ease of use, and durability. Users should look for models that can handle various projects and provide clear information. It’s all about making your work easier and more effective!

Maintenance of Digital Readout Systems

Best practices for maintaining and troubleshooting. Signs that indicate potential issues.Taking care of your digital readout systems is essential for keeping them working well. Regular maintenance helps spot problems early. Here are some best practices:

- Check connections and wires often.

- Clean the display and controls gently.

- Update software regularly.

- Calibrate the system as needed.

Signs that something might be wrong include a flickering display, inaccurate readings, or slow response. Paying attention to these signs helps prevent bigger issues.

What are common signs of a malfunctioning digital readout system?

Common signs include a dim or flickering display, strange error messages, and incorrect measurements. These issues can make it hard to use the machine safely.

Comparison of Controller Boards for Metal Lathes

Feature comparisons among leading brands. Price vs. performance analysis.Many brands offer various controller boards for metal lathes. Comparing their features helps you choose the best one. Key features may include display size, ease of use, and compatibility with tools. Price is also essential. Some boards are cheaper but may not work as well. Others might be more expensive but provide better performance. Here’s a quick comparison:

- Brand A: Large display, easy setup, mid-range price.

- Brand B: Compact display, less user-friendly, budget-friendly.

- Brand C: Advanced features, high price, best performance.

This information can help you decide which controller board fits your needs.

What is important in a controller board?

Look for features like display quality, price, and user experience. A good balance between performance and cost matters a lot.

Applications of Digital Readouts in Various Industries

Key industries using digital readouts. Specific use cases and benefits in production settings.Many industries love digital readouts for metal lathes because they make jobs easier and more accurate. Factories, automotive shops, and even woodworking places use them. They help workers measure and cut materials perfectly every time. Imagine trying to build a rocket with a ruler! Thanks to these tools, precision is as easy as pie. Here’s where you might find them:

| Industry | Use Case | Benefits |

|---|---|---|

| Manufacturing | Part production | Improves accuracy and reduces waste. |

| Automotive | Engine parts | Saves time and increases safety. |

| Woodworking | Furniture making | Makes crafting quicker and more fun. |

Upgrading Your Existing Lathe with a Digital Readout

Considerations for retrofitting older lathes. Costbenefit analysis of upgrading.Upgrading your lathe can bring many benefits. First, consider the age of your machine. Older lathes may need more parts and careful adjustments. This can add cost but can also improve performance. Here are some points to think about:

- Compatibility: Will a new digital readout fit your lathe?

- Cost: How much will the upgrade and installation cost?

- Skill Level: Can you install it yourself, or do you need help?

Next, think about the benefits. An upgrade can make work easier and more precise. This can save time and improve the quality of your projects. Sometimes, the costs of upgrading can be less than repairs for an older lathe. It’s wise to weigh these factors carefully.

Is it worth upgrading an old lathe?

Yes, it can improve accuracy and efficiency! A digital readout offers clear measurements. This makes tasks easier and more fun!

FAQs about Lathe Digital Readout Systems

Common questions and expert answers. Troubleshooting tips for users.If you’re diving into lathe digital readout systems, you might have some questions. Here are a few common ones!

| Question | Answer |

|---|---|

| How do I install the digital readout? | Check the manual! It usually has step-by-step instructions that are easier than assembling IKEA furniture. |

| What if my readout isn’t working? | First, check the power supply. If it’s plugged in, you might need to reset it. Power naps work wonders! |

| Do I need special tools? | Not really! Most setups need basic tools. Just don’t forget your favorite coffee mug for those intense lathe battles! |

For troubleshooting, always ensure that all wires are connected properly. Loose wires are like shy rabbits; they just want to hide! Remember, practice makes perfect. Happy lathe-ing!

Conclusion

In summary, a lathe digital readout makes using a metal lathe easier and more precise. It shows measurements clearly, helping you avoid mistakes. The controller board connects everything, letting you control the lathe better. If you’re interested in improving your metalworking skills, consider adding a digital readout. Explore more resources or tutorials to enhance your projects today!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout Metal Lathe Controller Boards:Sure! Here are five related questions about lathe digital readout metal lathe controller boards: 1. What is a lathe? A lathe is a machine that shapes metal or wood by spinning it around and cutting it. 2. What does a digital readout do? A digital readout shows numbers on a screen. It tells you how much you’ve cut or moved. 3. How does a controller board work? A controller board controls the machine’s movements. It helps you tell the lathe what to do. 4. Why are these tools helpful? They make it easier to get precise cuts. This helps us create better shapes and sizes. 5. Can anyone use this equipment? Yes, with some practice, anyone can learn to use it safely and effectively!

Sure! Just let me know the question you want me to answer, and I’ll provide a short response.

What Are The Key Features To Look For In A Digital Readout (Dro) System For A Metal Lathe?When choosing a digital readout (DRO) system for a metal lathe, you should look for a clear display. This helps you see the numbers easily. You want it to be simple to use, so you can learn quickly. Good accuracy is important for making precise cuts. Also, check if it has easy installation and good support if you need help.

How Does A Lathe Controller Board Improve The Precision And Efficiency Of Machining Operations?A lathe controller board helps machines work better and more accurately. It tells the lathe exactly where to move. This means cuts are cleaner and fit better together. You get your projects done faster and with fewer mistakes. That makes it easier for us to create cool things!

What Are The Differences Between Analog And Digital Readout Systems For Cnc Lathes?Analog readout systems show numbers on a dial or a moving needle. They can be hard to read accurately. Digital readout systems show numbers on a screen, making them easy to read. We use them to measure things more precisely. Overall, digital systems are clearer and more helpful for CNC lathes.

Can A Digital Readout Be Retrofitted Onto An Older Metal Lathe Model, And If So, What Are The Considerations?Yes, you can add a digital readout to an older metal lathe. First, check the space on your lathe for the new parts. You will need to find the right size and type of digital readout. Make sure it’s compatible and easy for you to install. Lastly, read the instructions carefully to avoid mistakes.

How Do You Troubleshoot Common Issues With Lathe Controller Boards And Digital Readout Displays?To troubleshoot problems with lathe controller boards and digital readout displays, start by checking the power supply. Make sure everything is plugged in and the switches are on. Next, look for loose or damaged wires. Tighten or replace them if needed. If the display isn’t working, reset the machine by turning it off and on again. Finally, consult the manual for error codes to understand specific issues.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readout Metal Lathe Controller Boards:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions about lathe digital readout metal lathe controller boards: 1. What is a lathe? A lathe is a machine that shapes metal or wood by spinning it around and cutting it. 2. What does a digital readout do? A digital readout shows numbers on a screen. It tells you how much you’ve cut or moved. 3. How does a controller board work? A controller board controls the machine’s movements. It helps you tell the lathe what to do. 4. Why are these tools helpful? They make it easier to get precise cuts. This helps us create better shapes and sizes. 5. Can anyone use this equipment? Yes, with some practice, anyone can learn to use it safely and effectively!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just let me know the question you want me to answer, and I’ll provide a short response.”}},{“@type”: “Question”,”name”: “What Are The Key Features To Look For In A Digital Readout (Dro) System For A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a digital readout (DRO) system for a metal lathe, you should look for a clear display. This helps you see the numbers easily. You want it to be simple to use, so you can learn quickly. Good accuracy is important for making precise cuts. Also, check if it has easy installation and good support if you need help.”}},{“@type”: “Question”,”name”: “How Does A Lathe Controller Board Improve The Precision And Efficiency Of Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A lathe controller board helps machines work better and more accurately. It tells the lathe exactly where to move. This means cuts are cleaner and fit better together. You get your projects done faster and with fewer mistakes. That makes it easier for us to create cool things!”}},{“@type”: “Question”,”name”: “What Are The Differences Between Analog And Digital Readout Systems For Cnc Lathes?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Analog readout systems show numbers on a dial or a moving needle. They can be hard to read accurately. Digital readout systems show numbers on a screen, making them easy to read. We use them to measure things more precisely. Overall, digital systems are clearer and more helpful for CNC lathes.”}},{“@type”: “Question”,”name”: “Can A Digital Readout Be Retrofitted Onto An Older Metal Lathe Model, And If So, What Are The Considerations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Yes, you can add a digital readout to an older metal lathe. First, check the space on your lathe for the new parts. You will need to find the right size and type of digital readout. Make sure it’s compatible and easy for you to install. Lastly, read the instructions carefully to avoid mistakes.”}},{“@type”: “Question”,”name”: “How Do You Troubleshoot Common Issues With Lathe Controller Boards And Digital Readout Displays?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To troubleshoot problems with lathe controller boards and digital readout displays, start by checking the power supply. Make sure everything is plugged in and the switches are on. Next, look for loose or damaged wires. Tighten or replace them if needed. If the display isn’t working, reset the machine by turning it off and on again. Finally, consult the manual for error codes to understand specific issues.”}}]}