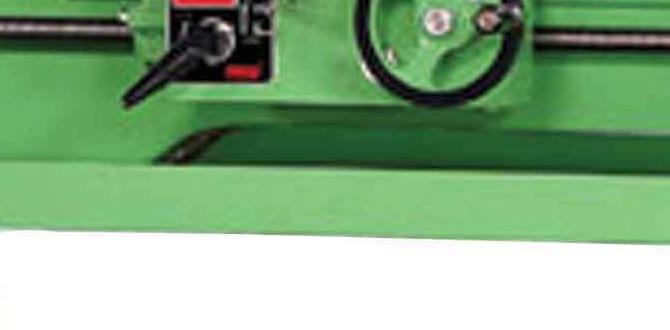

Have you ever wondered how metal parts are made with precision? A lathe is a machine that can turn raw metal into beautifully shaped pieces. One of the coolest tools for a lathe is the digital readout. This gadget shows exactly how much material you are removing. It makes the job easier and more accurate.

Imagine trying to carve a wooden figure without knowing how deep to go. That’s how important measurement is in metalworking. With a reliable digital readout, workers can achieve exact cuts every time.

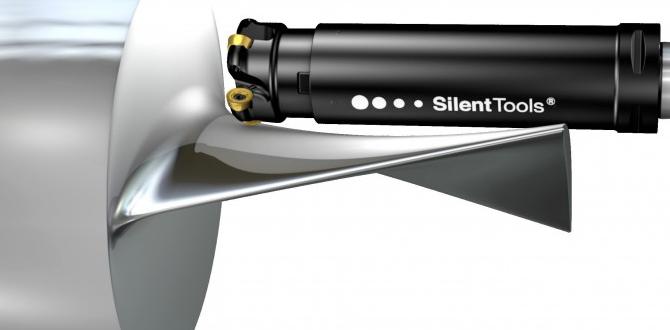

But what makes this tool stand out? It often connects to a metal lathe gear train. This gear train transfers movement accurately, allowing the digital readout to function seamlessly. Together, they help craftsmen create intricate designs with ease.

Did you know that using a digital readout can save time and material? Just think how much more you could make with this technology. You might be surprised at how small changes can lead to better creations.

Get ready to dive deeper into the world of lathes, digital readouts, and gear trains. You might form new ideas for your own projects!

Lathe Digital Readout: Enhancing Metal Lathe Gear Train Accuracy

Exploring Lathe Digital Readouts and Gear Trains

A lathe digital readout improves the accuracy of machining projects. Imagine checking measurements instantly instead of counting each turn! This tool connects to a metal lathe’s gear train, helping operators track movements precisely. It’s like having a high-tech assistant by your side. Did you know that using a digital readout can reduce human error? Understanding its features can make your projects easier and more successful, making it an essential part of modern machining.What is a Lathe Digital Readout?

Definition and purpose of digital readout systems.. Key features and benefits for metal lathes..A digital readout system shows the exact position of tools on a lathe. Imagine having a magic window that tells you where everything is! These systems make shaping metal much easier. Key features include clear displays and precise measurements. Also, they help you avoid mistakes, saving time and materials. Who wants to waste metal? Not us! With a digital readout, you can enjoy more accurate cuts and less guesswork. Is there any reason not to upgrade?

| Feature | Benefit |

|---|---|

| Clear Display | Easy to read and understand! |

| Precision | No more guesswork! |

| Error Reduction | Save metal and time! |

The Importance of Gear Trains in Metal Lathes

Explanation of gear trains and their function in lathes.. How gear trains impact precision and efficiency in machining..Gear trains play a crucial role in metal lathes. They help transfer power from the motor to the cutting tools. This makes the machine run smoothly and efficiently. Precision is vital in machining, and gear trains ensure accurate movements. With a proper gear setup, lathes can create better finishes and consistent shapes. In short, gear trains are essential for achieving high-quality results.

Why Are Gear Trains Important?

Gear trains boost both the speed and accuracy of metal lathes. They allow the operator to change speeds without losing control. This makes it easier to work on various materials.

- They help maintain steady motion.

- They increase the machine’s lifespan.

- They improve overall efficiency of the lathe.

How to Choose the Right Digital Readout for Your Lathe

Factors to consider when selecting a digital readout.. Recommended specifications for optimal performance..Choosing the right digital readout for your lathe makes a big difference. You should think about a few important factors:

- Accuracy: Select one with high precision.

- Display: Look for a clear screen for easy reading.

- Durability: Choose one that can handle tough work.

- Ease of use: A user-friendly interface saves time.

For optimal performance, consider these specifications:

- Minimum resolution of 0.001 inches.

- Support for both inch and metric measurements.

- Battery life for long usage without interruptions.

Your choice affects how well your lathe works.

What should you look for in a digital readout?

Look for high accuracy, a clear display, and strong durability. Make sure it is easy to use and supports different measurements.

Installation of Digital Readouts on Metal Lathes

Stepbystep guide to installation processes.. Common challenges and solutions during installation..Installing a digital readout on your metal lathe can feel like a puzzle, but don’t worry, we’ll crack it together! First, gather your tools and follow these simple steps:

| Steps | Description |

|---|---|

| 1. Prepare | Unplug the lathe and clean the workspace. |

| 2. Mount the Display | Secure the display in an easy-to-read spot. |

| 3. Install Sensors | Attach sensors to the axes. Make sure they can wiggle free—like a happy puppy! |

| 4. Connect Wires | Link the sensors to the display with care. |

| 5. Test It | Turn it on and check for accuracy. |

Common issues include misalignment and faulty wiring. For misalignment, let’s face it, no one loves a crooked readout! Ensure everything is snug and straight. For wiring troubles, double-check your connections. If all else fails, take a deep breath—remember, even the best technicians once faced the same quirky glitches!

Calibration and Maintenance of Digital Readouts

Importance of calibration for accuracy.. Routine maintenance tips to extend lifespan..Keeping your digital readout accurate is very important. Calibration helps it give correct measurements. Without it, mistakes can happen. Check your settings regularly to stay precise.

Routine maintenance is key to making your equipment last. Here are some simple tips:

- Clean the display often.

- Inspect the cables for wear.

- Store it in a dry place.

- Check for software updates.

Following these steps will help your digital readout work well for years.

Why is calibration important?

Calibration ensures accurate readings. It prevents errors that could lead to costly mistakes.

Common Issues and Troubleshooting with Digital Readouts

Identification of frequent problems users face.. Effective troubleshooting techniques and solutions..Digital readouts are great tools, but they can sometimes act like that grumpy cat that refuses to show affection! Common problems include flickering screens, unresponsive buttons, or incorrect readings. To troubleshoot, first check the connections; loose wires can create chaos. If the display is acting up, try resetting the device. Here’s a quick table to help you tackle these pesky issues:

| Common Issue | Solution |

|---|---|

| Flickering Screen | Check power connections |

| Unresponsive Buttons | Clean the keypad |

| Incorrect Readings | Reset the device |

Sometimes, a little patience and a good dose of humor can go a long way. Remember, even machines have bad days!

Enhancing Productivity with Digital Readouts

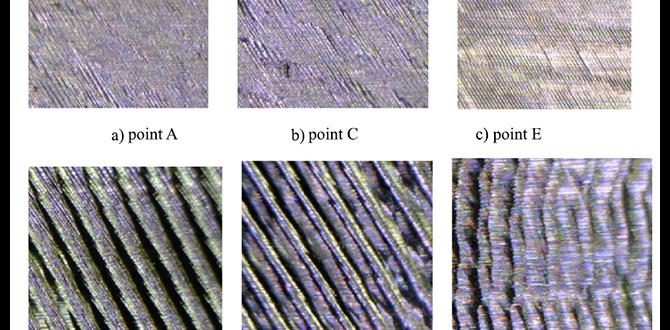

How digital readouts can improve workflow and efficiency.. Realworld examples of productivity enhancements..Using digital readouts helps make work faster and easier. They show exact measurements, cutting down on mistakes. This means less time fixing errors and more time creating. For example, a factory used digital readouts and saw a 20% boost in output. Workers wasted less time guessing and spent more time working efficiently.

- Shows clear measurements

- Reduces mistakes

- Improves speed

How can digital readouts boost productivity?

Digital readouts can increase accuracy and decrease errors. This allows workers to finish tasks faster and improve overall output.

Future Trends in Digital Readout Technology for Metal Lathes

Innovations and advancements in digital readouts.. Predictions for the future of lathe technology..New technology is always changing how we work with lathes. Digital readout systems are becoming smarter and easier to use. They show measurements clearly, helping users get their projects just right. Upcoming innovations may include:

- Touchscreen controls for easier navigation.

- Wireless connectivity for better data sharing.

- Built-in sensors to track machine health.

In the future, we can expect lathe technology to focus on even greater precision and user-friendliness. Imagine machines that learn from your work and suggest improvements!

What is the future of digital readouts in lathes?

The future of digital readouts in lathes looks bright and full of possibilities! Users can anticipate more accurate measurements and quicker setups, which will help them create better products faster.

Conclusion

In conclusion, a lathe digital readout improves accuracy and efficiency when using a metal lathe. Understanding the gear train helps you grasp how the machine works. By learning about these tools, you can enhance your skills and create better projects. We encourage you to explore more resources and practice on a lathe for hands-on experience!FAQs

Sure! Here Are Five Questions Related To The Topic Of Lathe Digital Readout Systems, Metal Lathes, And Gear Trains:Sure! Here are answers to some questions about metal lathes and digital readout systems. 1. **What is a metal lathe?** A metal lathe is a machine that helps us shape metal. We put a piece of metal on it, and the lathe spins it. Then, we can use tools to cut and shape the metal into different forms. 2. **What does a digital readout system do?** A digital readout system shows us exact measurements on a screen. It helps you know how much you have cut or shaped the metal. This makes it easier to get the right size. 3. **How does a gear train work?** A gear train is a series of gears that work together. When one gear moves, it makes the next gear move too. This helps us change how fast or slow something spins. 4. **Why are lathe machines important?** Lathe machines are important because they help us make many things from metal. We can create parts for cars, machines, and even toys. They help us be more precise when working with metal. 5. **Can you use a lathe to shape wood?** Yes, you can use a lathe to shape wood too! There are special lathes made for wood. They work in a similar way to metal lathes but are designed for softer materials.

Sure! Please provide the question you would like me to answer.

What Are The Key Advantages Of Using A Digital Readout (Dro) System On A Metal Lathe Compared To Traditional Vernier Scales?Using a digital readout (DRO) system on a metal lathe is easier than using traditional vernier scales. With a DRO, you can see numbers clearly on a screen. This helps you measure things quickly and accurately. You don’t have to guess or read tiny lines. Plus, DROs can save your measurements, so you don’t forget them!

How Does The Gear Train Configuration In A Lathe Affect Its Precision And Operational Efficiency?The gear train in a lathe helps it run smoothly. Different gear setups can change how fast or slow the lathe works. If the gears fit well, the lathe is more precise, which means your final product looks better. Good gears also make the lathe use energy more efficiently, saving time and effort. So, a good gear train means better work!

What Components Make Up The Gear Train In A Typical Metal Lathe, And How Do They Interact During Machining Operations?In a metal lathe, the gear train has gears, pulleys, and belts. These parts work together to change how fast the lathe spins. When you turn the handle, gears move, which helps cut the metal. The belts connect everything, so one part moves the others smoothly. This teamwork makes it easy for you to shape metal pieces.

How Can A Digital Readout System Improve The Accuracy And Repeatability Of Machining Operations On A Metal Lathe?A digital readout system shows you exact measurements on a screen. This helps you see numbers clearly and makes less mistakes. You can quickly measure how much to cut, so your pieces fit better. It lets you do the same job in the same way every time, which is called repeatability. With this system, we get better results faster!

What Types Of Error Compensation Features Are Available In Modern Digital Readout Systems For Metal Lathes To Enhance Performance?Modern digital readout systems for metal lathes have special features to help fix errors. One feature checks for mistakes in measurements and corrects them. Another feature helps keep track of tool wear, so you get better cuts. Some systems can also adjust for temperature changes that might affect size. These features help us get more accurate work done with our lathes.