Have you ever watched a metal lathe in action? It’s amazing how it transforms raw metal into beautiful parts. But did you know that using a lathe digital readout can make this process even better? Think about it. What if you could measure with perfect accuracy every single time you worked? Wouldn’t that make your projects easier and more fun?

Many people don’t realize the importance of a quill on a metal lathe. It helps control depth and precision. Imagine if you had the right tool at your fingertips, guiding you as you create. That’s the magic of combining a lathe digital readout with a quill.

In the world of metalworking, small details matter. Even a tiny mistake can ruin your project. This is where technology shines. When you have a digital readout, you can see measurements clearly. No more guessing or confusing numbers!

Let’s dive deeper into how these tools make metal lathes more efficient. Prepare to learn some fun facts and discover why every hobbyist and professional should consider this upgrade. Excited? You should be!

Lathe Digital Readout: Enhancing Metal Lathe Quill Accuracy

Understanding Lathe Digital Readouts for Metal Lathes

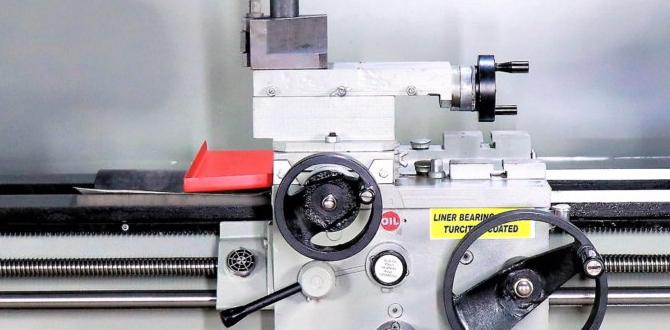

Lathe digital readouts enhance accuracy in metal lathe operations. These tools help measure distances precisely, making the work easier. Imagine trying to cut a piece of metal without knowing its exact size! That’s where a quill comes in handy. It allows for better control when adjusting tools. By using a digital readout, errors drop significantly. Curious minds will discover how even small improvements in measurement can lead to perfect results in metalworking.Importance of Digital Readout in Metal Lathes

Enhancements in precision and accuracy.. Impact on productivity and workflow efficiency..Using a digital readout on a metal lathe makes work easier and more precise. It shows exact measurements so you can cut accurately. With this tool, you can:

- Boost Precision: It helps in achieving exact sizes.

- Speed Up Work: You won’t waste time measuring multiple times.

By reducing errors, digital readouts can increase productivity. Workers get more done in less time, making everything run smoother. That’s why many lathes now use this technology.

Why is precision important in metal lathes?

Precision is key because it ensures every part fits perfectly. This leads to better products and less waste. Accurate measurements save materials and costs.

Components of a Lathe Digital Readout System

Key components: displays, sensors, and encoders.. How each component contributes to the overall functionality..A lathe digital readout system has three key parts: displays, sensors, and encoders. Each part plays a big role in making the system work well.

- Displays show important measurements clearly.

- Sensors detect positions of the tools.

- Encoders translate movement into electronic signals.

What are the main components of a lathe digital readout system?

The main components are displays, sensors, and encoders, which work together to track measurements accurately.

Installation Process of Digital Readout on Metal Lathes

Stepbystep guide to installation.. Common challenges and troubleshooting tips during installation..Installing a digital readout on your metal lathe can feel like a puzzle, but here’s an easy guide! First, gather your tools—screwdrivers, a level, and maybe a snack because who doesn’t get hungry? Start by securing the display unit to a stable spot. Next, connect the sensors to the quill; it’s like giving your lathe a new pair of eyes! If something doesn’t work, check the wiring—don’t be afraid to channel your inner detective.

| Common Challenges | Troubleshooting Tips |

|---|---|

| Wiring Issues | Check connections and ensure they’re tight! |

| Inaccurate Readings | Calibrate your readout properly. |

| Display Malfunctions | Reset and inspect for damage. |

Remember, no one said installation was easy, but with patience, your lathe will shine like new—ready to work with precision!

Features to Consider When Choosing a Digital Readout

Essential features for optimal performance.. Comparison of top digital readout brands and models..Choosing a digital readout can feel like trying to pick your favorite ice cream flavor—so many options! First, **essential features** like accuracy and ease of use matter the most. Look for displays that show measurements clearly and are easy to read, even for tired eyes. Next, check how the readout connects to your lathe. Some models play nice with different machines. Also, compare brands for customer reviews; you wouldn’t want a chuckle-worthy option that’s more trouble than it’s worth.

| Brand | Model | Key Features |

|---|---|---|

| Brand A | Model X | High accuracy, user-friendly |

| Brand B | Model Y | Great compatibility, bright display |

| Brand C | Model Z | Long battery life, durable |

Maintenance Tips for Longevity of Digital Readouts

Regular maintenance practices to enhance lifespan.. Signs indicating the need for recalibration or repair..To keep your digital readouts in top shape, regular checks are a must. Clean the screen and connections often, just like you’d wash your hands before dinner. Look out for signs like flickering screens or strange readings—this could mean it’s time for recalibration or repair. A well-maintained readout can last longer, saving you from unexpected surprises. Remember, even machines appreciate a little TLC!

| Maintenance Tip | Signs of Trouble |

|---|---|

| Regular cleaning | Flickering display |

| Check cables | Inaccurate measurements |

| Routine calibration | Unexpected shutdowns |

Common Mistakes to Avoid with Lathe Digital Readouts

Misinterpretation of readings and its consequences.. Installation errors that can affect performance..Misinterpreting reads on your lathe digital readout metal lathe quill can lead to big problems. You might cut too deep or too shallow, ruining your work.

Improper installation can also mess up your machine. It may show wrong measurements or fail to respond. Avoid these mistakes for better accuracy.

Here are common issues:

- Incorrect decimal point use.

- Loose cables during setup.

- Not zeroing the machine before starting.

What happens if the readings are wrong?

If readings are wrong, you might waste material and time. It’s crucial to double-check your settings.

How can installation errors affect lathe performance?

Installation errors can cause inaccurate cuts, leading to costly mistakes and poor results.

Advancements in Digital Readout Technology

Recent innovations in digital readout features.. Future trends and their implications for users..Digital readout technology is zooming ahead like a squirrel on espresso. Recent innovations include color screens and touch interfaces, making it easier for users to read measurements. Imagine not squinting at numbers like a confused owl! Future trends point toward features like AI integration, which could predict tool wear. This means users spend less time replacing tools and more time making cool stuff. Exciting, isn’t it? We might even get machines that can tell us silly jokes while we work!

| Innovation | Feature | Benefits |

|---|---|---|

| Color Displays | Clear visuals | Easy readability |

| Touch Interfaces | User-friendly | Quick adjustments |

| AI Integration | Smart predictions | Improved efficiency |

User Experiences and Reviews

Realworld examples of lathe operators using digital readouts.. Analysis of user feedback on various models..Many lathe operators share positive experiences using digital readouts. They often mention that these tools make it easier to measure and cut materials precisely. Here are some insights from users:

- Digital readouts help reduce mistakes.

- Operators appreciate clear and bright displays.

- Many users find installation simple and straightforward.

Some users feel that certain models slow down their work. Others wish for more detailed manuals. Overall, feedback shows these tools are a valued addition to many workshops.

What do users say about digital readouts?

Users often praise digital readouts for enhancing accuracy and speed in their work. Many value the ease of use in daily tasks, which reduces errors.

Conclusion

In summary, a digital readout for a metal lathe quill enhances precision and ease of use. It helps you measure and adjust accurately, improving your projects. To get started, consider exploring different readout systems. You can also watch tutorials online to see how they work in action. With practice, you’ll master your lathe skills quickly!FAQs

What Are The Primary Advantages Of Using A Digital Readout System On A Metal Lathe Quill Compared To Traditional Measurement Methods?Using a digital readout system on a metal lathe quill makes measuring easier and faster. You see numbers on a screen, so it’s clear how much you’ve moved. This helps you be more accurate and avoid mistakes. With buttons, you can quickly change settings, which saves time. Overall, it makes your work smoother and more fun!

How Do You Properly Calibrate A Digital Readout For Accurate Measurements On A Lathe Quill?To calibrate a digital readout on a lathe quill, first, make sure the machine is turned off. Next, use a standard measuring tool, like a ruler or caliper, to measure the quill length. Then, turn on the digital readout and adjust the numbers to match the measurement. Finally, test it again by measuring different lengths to see if it’s correct. If the readings match, you’re all set!

Can A Digital Readout Display Provide Real-Time Feedback On Quill Position During Machining Operations?Yes, a digital readout display can show you the exact position of the quill while you work. This helps you see how much you are moving it. You get to see the changes right away, so you know if you need to adjust. It makes your machining work easier and safer!

What Features Should You Look For When Selecting A Digital Readout Specifically For A Metal Lathe Quill?When choosing a digital readout for a metal lathe quill, look for a clear display. You want to see numbers easily. Make sure it has good accuracy to help you measure correctly. You should also check if it’s easy to install. Lastly, find one that works well in different lighting conditions.

How Do You Troubleshoot Common Issues Encountered With Digital Readouts On Metal Lathe Quills?To fix problems with digital readouts on metal lathe quills, you should start by checking the power supply. Make sure everything is plugged in and the batteries are fresh. Next, look for loose wires or damaged parts. If the display is not working, try resetting the machine. Lastly, if it still doesn’t work, ask someone with more experience for help.