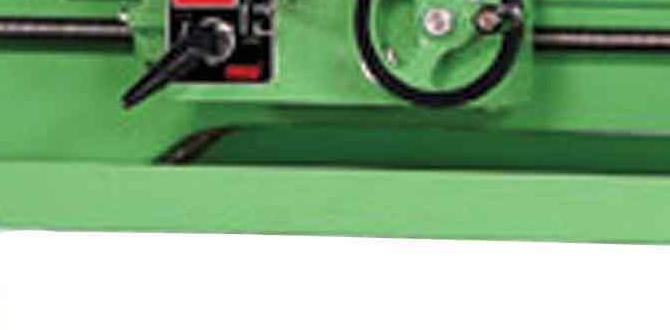

Have you ever watched a metal lathe in action? It’s fascinating to see how metal is shaped and formed. A lathe digital readout makes this process even more interesting. It gives you precise measurements as you work. This ensures accuracy, which is super important.

Did you know that torque plays a huge role in how lathes work? Torque is the force that helps the lathe spin. Understanding it can improve your projects. Imagine creating a perfect piece of metal art with ease!

If you’ve ever felt excited about building something cool, this article is for you. We will explore how a lathe digital readout and torque can elevate your metalworking skills. Ready to dive in? Let’s get started!

Lathe Digital Readout: Enhancing Metal Lathe Torque Precision

Lathe Digital Readout Metal Lathe Torque

Discover how a digital readout enhances the experience of using a metal lathe. It helps you measure torque precisely, making your work accurate and efficient. Have you ever struggled to get the right measurements? With a digital readout, those worries fade away! Fun fact: precise torque settings can lead to longer tool life. A digital readout can transform your metal lathe from a simple tool into a powerhouse for your projects. Explore how it enhances your crafting journey!Understanding Digital Readouts (DRO) for Lathes

Definition and purpose of digital readouts in metalworking. Advantages of using DROs over traditional measurement methods.Digital readouts (DROs) are tools that show precise measurements on metal lathes. They help workers see exact numbers for cutting and shaping metal. The main purpose of DROs is to improve accuracy and speed in metalworking.

Compared to traditional methods, DROs have great benefits:

- They reduce errors in measuring.

- They are easy to read from different angles.

- They save time by quickly updating measurements.

- They help create detailed and precise workpieces.

Using DROs can make a big difference in metalworking tasks!

What are the benefits of DROs for metal lathes?

Using DROs can improve your work by providing better accuracy and faster results. Expect less waste and a smoother design process.

Importance of Torque in Metal Lathes

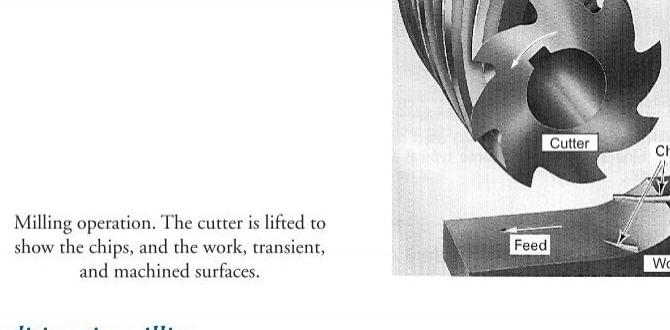

Explanation of torque and its role in lathe operations. How torque affects precision and efficiency in metal machining.Torque is a measure of how much force can cause an object to rotate. In metal lathes, torque is vital for making precise cuts. High torque means the lathe can work through tough metals easily. This makes the process faster and more efficient. When a lathe has the right torque:

- It maintains speed during tough tasks.

- It reduces the chance of mistakes.

- It improves the quality of the final product.

Strong torque leads to better results and less time wasted. Using torque wisely helps machinists achieve their goals with confidence.

Why is torque important for precision?

Torque ensures smooth cutting, which helps create precise shapes in metal. Without it, machines can stall and ruin projects.

Choosing the Right Digital Readout for Your Lathe

Key features to look for in a lathe DRO. Comparison of different types and models available in the market.When picking a digital readout for your lathe, focus on features that make your life easier. Look for a clear display, simple controls, and sturdy construction. A good readout helps you work better. Isn’t that what we all want? There are many models out there, each with its perks. Some are super advanced, while others are as basic as a rubber duck! Here’s a fun comparison:

| Model | Display Type | Accuracy | Price |

|---|---|---|---|

| Super-DRO 3000 | LCD | ±0.001 | $150 |

| Easy-Read DRO | LED | ±0.01 | $100 |

| Pro-DRO 5000 | Touchscreen | ±0.001 | $200 |

Fun fact: the best model for you depends on how much torque you need. Think about what you’ll make and pick wisely!

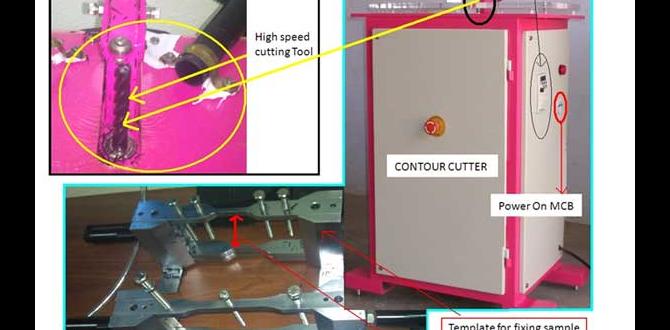

Installation Process for Lathe Digital Readouts

Stepbystep guide to installing a DRO on a metal lathe. Common challenges and troubleshooting tips during installation.Ready to make your metal lathe smarter? Follow these simple steps for installing a digital readout (DRO). First, gather your tools: a screwdriver, some screws, and of course, your DRO! Mount the display where you can see it easily. Next, connect the encoders to the lathe and the display. Remember, connections matter! Some may face basic hiccups, like loose wires. Check everything twice and tighten up any loose ends. If you hit a snag, don’t panic; call it your “lathese”! Here’s a quick table to help:

| Step | Action |

|---|---|

| 1 | Gather tools |

| 2 | Mount the display |

| 3 | Connect encoders |

| 4 | Tighten connections |

Now you’re ready to rock with your new DRO setup!

Calibration of Lathe Digital Readouts

Importance of calibrating your DRO for accurate readings. Procedures for calibrating a digital readout system.Calibrating your digital readout (DRO) is vital for getting correct readings on your lathe. Imagine trying to bake a cake without a proper recipe! Calibration ensures your measurements are accurate. Here are simple steps to calibrate your DRO:

| Steps | Description |

|---|---|

| 1. Zero your DRO | Start from a known point. This sets a solid base. |

| 2. Measure | Use a ruler or gauge to check distances. |

| 3. Adjust | If numbers don’t match, tweak the settings! |

| 4. Repeat | Keep checking until your readout is spot on! |

Calibrating improves precision, making your projects smoother. Remember, even the best chefs measure twice! Don’t skip this step, or your lathe may serve you some questionable results!

Case Studies: Successful Applications of DROs in Metal Lathes

Realworld examples of improved performance with DROs. Lessons learned from businesses that implemented digital readouts.Using digital readouts, or DROs, in metal lathes has shown great results. For instance, one machine shop saw a 30% boost in productivity. They found that the DRO helped workers measure more accurately. Another company reported less waste after using a DRO, saving them money. Key lessons from these examples include:

- Accuracy leads to less waste.

- DROs make it easier for workers to learn new skills.

- Investing in modern tools increases efficiency.

Maintenance Tips for Longevity of Lathe Digital Readouts

Routine maintenance practices to keep DROs functioning optimally. Signs that indicate a need for repair or replacement.To keep your lathe digital readout in top shape, regular check-ups are key. Clean it gently to avoid dust bunnies and sticky buttons. Listen for odd noises, and if it starts to act like a grumpy cat, it might need repairs. If the display stutters or loses accuracy, it’s time to pay attention. Don’t wait until it throws a tantrum! Here’s a quick look at some signs that help you understand when your DRO needs care:

| Signs of Trouble | What to Do |

|---|---|

| Flickering Display | Check the connections! |

| Incorrect Measurements | Time for recalibration! |

| Buttons Sticking | Give them a cleaning! |

Keeping an eye on these signs will help your lathe digital readout last longer! After all, a happy DRO means happy machining!

Conclusion

In summary, a lathe digital readout helps you measure precisely on a metal lathe. Understanding torque is vital for safe operation, ensuring your projects go smoothly. By mastering these tools, you can improve your metalworking skills. We encourage you to explore tutorials or guides on using digital readouts and managing torque effectively for better results in your projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readouts, Metal Lathes, And Torque:Sure! Here are three questions you can ask about lathes and their tools. 1. What is a lathe? A lathe is a machine that shapes metal and wood. It spins the material while tools cut it into different shapes. 2. What is a digital readout? A digital readout shows precise measurements on a screen. It helps you know exactly where to cut. 3. What does torque mean? Torque is how much force you use to turn something. In a lathe, it helps cut materials smoothly.

Sure! Just send me the question you want answered, and I’ll help you with a simple and clear response.

What Are The Primary Benefits Of Using A Digital Readout System On A Metal Lathe For Precision Machining?A digital readout system makes measuring easier and faster on a metal lathe. It shows numbers clearly, so you can see exactly how much to move the tools. This helps create parts that fit perfectly. You make fewer mistakes and save time. Overall, it makes your work better and simpler.

How Does Torque Impact The Performance And Efficiency Of A Metal Lathe When Machining Various Materials?Torque is the twisting force a lathe uses to turn metal. When you machine tougher materials, you need more torque. This means the lathe can cut better and faster. If the torque is too low, the lathe might slow down or even stop, making it less efficient. So, having the right torque helps you get good results when working with different metals.

What Features Should One Look For In A High-Quality Digital Readout System For Use On A Metal Lathe?When choosing a digital readout system for a metal lathe, look for clear displays. You want numbers that are easy to read. Check if it offers simple controls so you can use it without fuss. Good accuracy is important too, as this helps make precise cuts. Finally, make sure it can fit your machine well.

How Can Torque Measurement Be Integrated With A Digital Readout System To Enhance Precision In Machining Operations?We can connect a torque sensor to a digital screen. This sensor measures how much twist or force is applied when we turn a tool. When you look at the digital readout, you see real-time numbers. This helps you know exactly how much force to apply, making your work more accurate. So, you get better results in your machining tasks.

What Maintenance Practices Are Necessary To Ensure The Accuracy And Longevity Of A Digital Readout System On A Metal Lathe?To keep the digital readout system on a metal lathe working well, you should clean it regularly. Dust and dirt can mess up the readings. Make sure all the connections are tight and free from damage. You can also check for updates or new software to keep it running smoothly. Lastly, store the lathe in a dry place to avoid rust or moisture problems.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Digital Readouts, Metal Lathes, And Torque:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are three questions you can ask about lathes and their tools. 1. What is a lathe? A lathe is a machine that shapes metal and wood. It spins the material while tools cut it into different shapes. 2. What is a digital readout? A digital readout shows precise measurements on a screen. It helps you know exactly where to cut. 3. What does torque mean? Torque is how much force you use to turn something. In a lathe, it helps cut materials smoothly.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Just send me the question you want answered, and I’ll help you with a simple and clear response.”}},{“@type”: “Question”,”name”: “What Are The Primary Benefits Of Using A Digital Readout System On A Metal Lathe For Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A digital readout system makes measuring easier and faster on a metal lathe. It shows numbers clearly, so you can see exactly how much to move the tools. This helps create parts that fit perfectly. You make fewer mistakes and save time. Overall, it makes your work better and simpler.”}},{“@type”: “Question”,”name”: “How Does Torque Impact The Performance And Efficiency Of A Metal Lathe When Machining Various Materials?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Torque is the twisting force a lathe uses to turn metal. When you machine tougher materials, you need more torque. This means the lathe can cut better and faster. If the torque is too low, the lathe might slow down or even stop, making it less efficient. So, having the right torque helps you get good results when working with different metals.”}},{“@type”: “Question”,”name”: “What Features Should One Look For In A High-Quality Digital Readout System For Use On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When choosing a digital readout system for a metal lathe, look for clear displays. You want numbers that are easy to read. Check if it offers simple controls so you can use it without fuss. Good accuracy is important too, as this helps make precise cuts. Finally, make sure it can fit your machine well.”}},{“@type”: “Question”,”name”: “How Can Torque Measurement Be Integrated With A Digital Readout System To Enhance Precision In Machining Operations?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “We can connect a torque sensor to a digital screen. This sensor measures how much twist or force is applied when we turn a tool. When you look at the digital readout, you see real-time numbers. This helps you know exactly how much force to apply, making your work more accurate. So, you get better results in your machining tasks.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Are Necessary To Ensure The Accuracy And Longevity Of A Digital Readout System On A Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the digital readout system on a metal lathe working well, you should clean it regularly. Dust and dirt can mess up the readings. Make sure all the connections are tight and free from damage. You can also check for updates or new software to keep it running smoothly. Lastly, store the lathe in a dry place to avoid rust or moisture problems.”}}]}