Have you ever watched a metal lathe work? It’s like magic! The way it shapes metal can truly impress anyone.

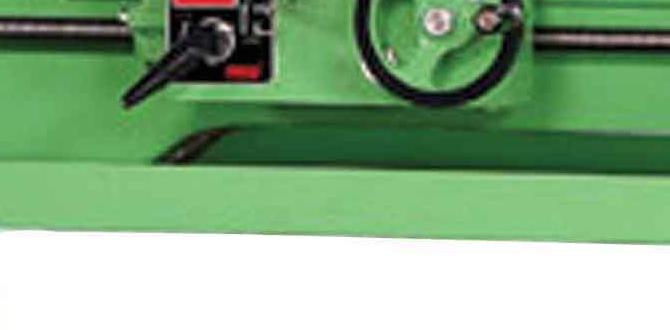

In the world of machining, the lathe floor mount metal lathe is an essential tool. This powerful machine helps you create parts with amazing precision. But what makes the compound rest so important?

The compound rest is like the lathe’s best friend. It allows for smooth and accurate movement, making it easier to carve details into metal. Imagine trying to make a tiny cut on a piece of metal. Without the compound rest, it would be tough!

A fun fact: Did you know that some lathes have been around since ancient times? They were simple back then but have evolved into the complex machines we see today.

In this article, we will explore the lathe floor mount metal lathe and its compound rest. You will learn how they work together to help you create amazing things. So, are you ready to dive in?

Lathe Floor Mount Metal Lathe Compound Rest: Essential Guide

Lathe Floor Mount Metal Lathe Compound Rest

What makes a lathe compound rest special? This tool is crucial for precision when working with metal. It helps shape, cut, and finish projects smoothly. Did you know that a well-adjusted compound rest can improve your work quality significantly? Knowing its parts, like the cross-slide and tool holder, empowers you to create accurate pieces. Whether you’re a beginner or expert, mastering the compound rest opens doors to more complex projects and tools.What is a Floor Mount Metal Lathe?

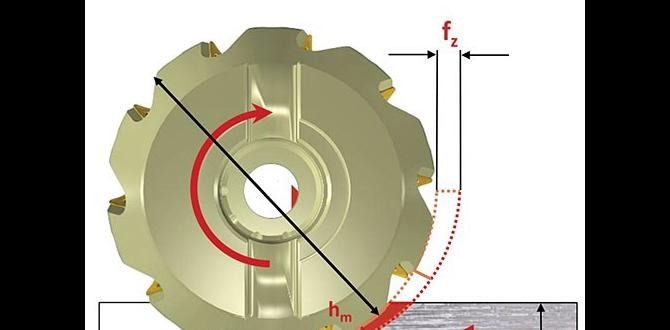

Definition and significance in metalworking. Typical applications and industries using floor mount lathes.A floor mount metal lathe is a powerful machine used to shape metal. It spins metal pieces while cutting tools remove material, making precise items. This machine is important in metalworking because it helps create parts for many products.

- Common applications include making gears, shafts, and tools.

- Industries like automotive, aerospace, and manufacturing use floor mount lathes.

They are essential for creating accurate and durable metal objects. Without them, many everyday items would not exist!

What are the advantages of using a floor mount metal lathe?

The advantages include high precision in metalworking, capability to handle larger pieces, and greater stability during operation.

Understanding the Compound Rest

Explanation of the compound rest and its components. The role of the compound rest in precision machining.The compound rest is a key part of a lathe. It holds and moves the cutting tool. Think of it like a tiny ride for the tool, helping it stay on its path. The main components include the slide, the handwheel, and the tool holder. Each part works together to shape metal with great precision. Precision machining is all about making exact cuts. If the compound rest isn’t adjusted right, it’s like trying to ride a bicycle with a flat tire—definitely not fun!

| Component | Function |

|---|---|

| Slide | Moves the tool side to side. |

| Handwheel | Controls the position of the tool. |

| Tool Holder | Securely holds the tool in place. |

In the world of machines, the compound rest is like the compass for a sailor—guiding the tool to make those perfect cuts!

Benefits of Using a Floor Mount Metal Lathe

Enhanced stability and precision compared to benchmounted lathes. Increased durability and capacity for larger workpieces.Using a floor mount metal lathe offers fantastic benefits! First, it provides enhanced stability and precision, which means you won’t end up with wobbly creations. Think of it as the difference between building a treehouse in a windstorm vs. on solid ground. Sturdy support keeps your work accurate!

Second, these lathes are built to last. They can handle larger workpieces, making them perfect for big projects. No more wrestling with tiny parts like they’re in a wrestling match! Plus, the durability means fewer repairs, and that’s always a win!

| Benefits | Details |

|---|---|

| Stability | Less wobbling, more precision. |

| Durability | Can handle big pieces without issues. |

Key Features to Look for in a Compound Rest

Material quality and construction. Adjustability and ease of use.Finding the right compound rest is key to smooth turning operations. First, check the material quality and construction. A good rest should be made from solid materials like cast iron or durable aluminum. They are tough and help to prevent wear and tear. Next, consider adjustability and ease of use. You want something that can be easily fine-tuned. A wobbly rest is worse than trying to balance a rubber chicken on your head! Easy adjustments save time, and every second counts in a workshop.

| Feature | Importance |

|---|---|

| Material Quality | Durability and stability |

| Adjustability | Ease in operation |

How to Properly Set Up a Floor Mount Metal Lathe

Stepbystep installation process. Importance of leveling and securing the lathe.Setting up your lathe is like building a sandcastle, except it won’t wash away! Begin by placing your lathe on a sturdy floor (no weak floors allowed!). Make sure it’s level; a wobbly lathe is like a tightrope walker without a pole! Use a spirit level and adjust the feet until it’s perfect. Next, secure the lathe with bolts to prevent any surprises. Also, keep the area clear. A safe space is a happy space!

| Step | Action |

|---|---|

| 1 | Choose a steady location |

| 2 | Level the lathe |

| 3 | Secure it tightly |

| 4 | Clear your workspace |

Common Issues and Troubleshooting Tips

Identifying and resolving common compound rest problems. Maintenance practices to ensure optimal performance.Many users face problems with the compound rest on their lathe. These issues can slow down your work. To keep your machine running smoothly, look out for these signs:

- Sticking movements

- Loose parts

- Inaccurate cuts

Regular maintenance can prevent these problems. Here are some tips:

- Keep the area clean.

- Lubricate moving parts.

- Check for wear and tear.

With a little care, your lathe will run like new!

What are common problems with a compound rest?

Common problems include sticking movements, loose parts, and inaccurate cuts. Regular checks and maintenance can help fix these issues.

How can I maintain my compound rest?

- Regularly clean the area.

- Lubricate moving parts.

- Inspect for wear and damage.

Safety Precautions While Using a Metal Lathe

Essential safety gear and equipment. Best practices for safe operation.Using a metal lathe can be fun, but safety comes first. Always wear proper safety gear like goggles and gloves. These keep your eyes and hands protected, just in case something goes “bing!” Helmets are great too, especially if you have a “head full of ideas” to keep safe. Follow the best practices: keep the workspace tidy, never rush, and use the correct speed settings. Remember, a clean shop means a happy shop!

| Safety Gear | Purpose |

|---|---|

| Goggles | Protect your eyes from flying debris. |

| Gloves | Keep your hands safe from sharp edges. |

| Ear Protection | Prevent damage from loud noises. |

| Apron | Shield your clothes from metal shavings. |

Conclusion

In summary, a lathe floor mount metal lathe with a compound rest is essential for precise cutting. It helps you make accurate angles and shapes. We learned that this tool can improve your projects significantly. If you’re interested in metalworking, consider getting one. Explore more about using a lathe, and start creating amazing designs today!FAQs

Sure! Here Are Five Questions Related To Lathe Floor Mount Metal Lathe Compound Rest:Sure! A lathe is a machine that helps shape metal. The compound rest is a part that helps us move the cutting tool. You can adjust it to make different shapes and angles. It’s important for making precise cuts. Remember to be careful while using it!

Sure! Please provide the question you’d like me to answer.

What Is The Purpose Of The Compound Rest In A Floor-Mounted Metal Lathe, And How Does It Enhance Machining Precision?The compound rest is a part of a metal lathe that helps us make precise cuts. It can move in different directions, allowing us to shape the metal exactly how we want. By adjusting the compound rest, we can get very accurate angles and shapes. This makes our work cleaner and better, so we get the job done right.

How Do You Properly Align And Adjust The Compound Rest On A Floor Mount Metal Lathe For Accurate Cutting?To align and adjust the compound rest on a metal lathe, first, make sure the machine is off and safe. Next, check if the compound rest is level by using a square tool. You want it to sit flat and straight, without any gaps. Then, tighten the screws gently to hold it in place. Finally, test it by cutting a small piece of metal to see if it works well.

What Are The Common Materials Used For Manufacturing Compound Rests On Metal Lathes, And How Do They Affect Performance?Common materials used for making compound rests on metal lathes include cast iron, aluminum, and steel. Cast iron is strong and heavy, which helps keep it steady while you work. Aluminum is lighter and easier to move, but it can be less strong. Steel is strong and durable, making it perfect for tough jobs. Each material affects how well the lathe performs, helping us make accurate shapes and cut materials easily.

What Maintenance Practices Should Be Followed For The Compound Rest To Ensure Longevity And Optimal Performance Of A Lathe?To keep the compound rest of a lathe in good shape, clean it regularly. Dust and chips can cause problems, so wipe it down after use. You should also oil it lightly to keep the parts moving smoothly. Always check for any loose screws and tighten them if needed. If you take care of it, the lathe will work better and last longer!

How Can You Troubleshoot Common Issues Associated With The Compound Rest On A Floor-Mounted Metal Lathe, Such As Backlash Or Instability During Operation?To fix problems with the compound rest on a metal lathe, start by checking for loose screws. Tighten any loose parts to reduce movement. If there’s backlash, or extra play, adjust the gibs. Gibs are small pieces that help hold everything tight. By adjusting them, you help keep the lathe steady while you work.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Questions Related To Lathe Floor Mount Metal Lathe Compound Rest:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a machine that helps shape metal. The compound rest is a part that helps us move the cutting tool. You can adjust it to make different shapes and angles. It’s important for making precise cuts. Remember to be careful while using it!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you’d like me to answer.”}},{“@type”: “Question”,”name”: “What Is The Purpose Of The Compound Rest In A Floor-Mounted Metal Lathe, And How Does It Enhance Machining Precision?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The compound rest is a part of a metal lathe that helps us make precise cuts. It can move in different directions, allowing us to shape the metal exactly how we want. By adjusting the compound rest, we can get very accurate angles and shapes. This makes our work cleaner and better, so we get the job done right.”}},{“@type”: “Question”,”name”: “How Do You Properly Align And Adjust The Compound Rest On A Floor Mount Metal Lathe For Accurate Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To align and adjust the compound rest on a metal lathe, first, make sure the machine is off and safe. Next, check if the compound rest is level by using a square tool. You want it to sit flat and straight, without any gaps. Then, tighten the screws gently to hold it in place. Finally, test it by cutting a small piece of metal to see if it works well.”}},{“@type”: “Question”,”name”: “What Are The Common Materials Used For Manufacturing Compound Rests On Metal Lathes, And How Do They Affect Performance?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common materials used for making compound rests on metal lathes include cast iron, aluminum, and steel. Cast iron is strong and heavy, which helps keep it steady while you work. Aluminum is lighter and easier to move, but it can be less strong. Steel is strong and durable, making it perfect for tough jobs. Each material affects how well the lathe performs, helping us make accurate shapes and cut materials easily.”}},{“@type”: “Question”,”name”: “What Maintenance Practices Should Be Followed For The Compound Rest To Ensure Longevity And Optimal Performance Of A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep the compound rest of a lathe in good shape, clean it regularly. Dust and chips can cause problems, so wipe it down after use. You should also oil it lightly to keep the parts moving smoothly. Always check for any loose screws and tighten them if needed. If you take care of it, the lathe will work better and last longer!”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues Associated With The Compound Rest On A Floor-Mounted Metal Lathe, Such As Backlash Or Instability During Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix problems with the compound rest on a metal lathe, start by checking for loose screws. Tighten any loose parts to reduce movement. If there’s backlash, or extra play, adjust the gibs. Gibs are small pieces that help hold everything tight. By adjusting them, you help keep the lathe steady while you work.”}}]}