Have you ever watched a machinist work on a project? It’s fascinating to see how they turn metal into art. One tool that plays a crucial role in this process is the lathe, especially the floor mount metal lathe motor.

Picture this: a large metal machine with spinning parts, creating precise shapes. The floor mount design allows it to stand firmly, giving users control and stability. This setup is perfect for hobbyists and professionals alike.

Did you know that lathe machines have been around for thousands of years? They started as simple tools and have evolved into powerful machines. Today, with the right floor mount metal lathe motor, anyone can create amazing projects.

In this article, we’ll explore how this motor works, its benefits, and what you need to know before using it. Are you ready to dive into the world of lathes? Let’s get started!

Lathe Floor Mount Metal Lathe Motor: Key Features Explained

Understanding the Lathe Floor Mount Metal Lathe Motor

Do you know how important a motor is for a lathe machine? A lathe floor mount metal lathe motor powers the lathe, making it spin and work with heavy metal pieces. Choosing the right motor is crucial for efficiency and performance. These motors come in various sizes and strengths, matching different lathes. Using the correct motor can enhance your projects significantly. Imagine completing a challenging task faster and better. Understanding motors helps you improve your crafting skills.Understanding Lathe Floor Mounts

Explanation of lathe floor mount designs and purposes. Benefits of using floor mounts for stability and precision.Lathe floor mounts are important for many reasons. They hold the lathe steady while it works. Different designs offer unique features to enhance its use. A strong base ensures that the lathe doesn’t move. This is crucial for precision cutting. Benefits of using these mounts include:

- Improved stability

- Better accuracy

With a secure floor mount, users can make finer details in their work. This makes projects look more professional and neat.

What are the uses of lathe floor mounts?

Lathe floor mounts are used to provide stability and precision during metalworking tasks.

Selecting the Right Motor for Your Lathe

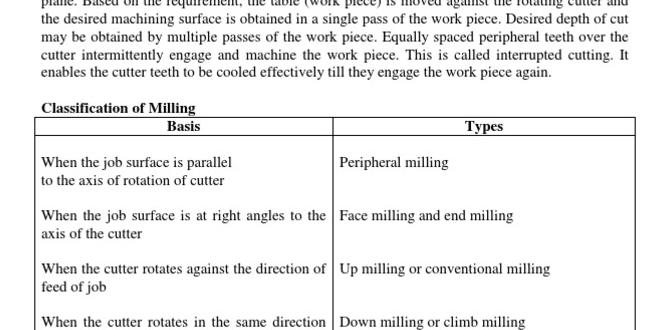

Key factors to consider when choosing a motor (power, torque, speed). Tips for matching motor specifications with lathe requirements.Choosing a motor for your lathe can feel like picking a superhero’s sidekick. You need to find one that has the right power, torque, and speed to get the job done. Think of power like muscle—more is usually better! Torque helps you tackle tough jobs, while speed lets you zoom through easy tasks. Be sure to check your lathe’s requirements before you buy. Match the motor specs like a puzzle. The right fit means smoother work and less hassle. Here’s a quick guide to help:

| Factor | Key Points |

|---|---|

| Power | Choose a motor with enough horsepower for your projects. |

| Torque | Look for higher torque for heavier materials. |

| Speed | Speed needs to match your lathing speed requirements. |

Remember, picking the right motor is like finding a good friend. You want one that can handle the tough times and keep up with the fun!

Installing a Metal Lathe Motor on a Floor Mount

Stepbystep guide to installing the motor safely and securely. Common pitfalls to avoid during installation process.Installing a metal lathe motor on a floor mount is easy if you follow a few simple steps. First, gather your tools and read the manual. Then, safely attach the motor to the mount, ensuring it sits evenly. Tighten all screws, but not too tight—no one likes over-tightened bolts! Watch out for common mistakes like forgetting to connect the power or misplacing washers. Follow this checklist:

| Step | Tip |

|---|---|

| 1. Gather Tools | Don’t start without a wrench! |

| 2. Attach Motor | Make sure it’s balanced. Imagine a seesaw! |

| 3. Tighten Screws | Not like you’re opening a jar! |

Finally, double-check your work. You don’t want to make your lathe motor play hide and seek with you!

Maintenance of Lathe Motors

Routine maintenance tasks to prolong motor lifespan. Troubleshooting common motor issues and solutions.Keeping your lathe motor in good shape is easy with some simple steps. First, check the motor’s cleanliness. Remove dust and debris regularly. This helps it run better and last longer. Next, keep the motor lubricated as per the manufacturer’s instructions. This prevents overheating.

If something goes wrong, start by checking the power supply. Ensure there is electricity. Then, listen for unusual sounds. If you hear weird noises, it may need repair. Keep a look out for these issues to keep your lathe motor running well!

What are some common issues with lathe motors?

Common issues include overheating, strange noises, and power failures. Regular checks help identify and fix these problems early.

Tips for troubleshooting:

- Check the wiring.

- Look for loose connections.

- Inspect the bearings.

- Make sure it’s properly cooled.

Enhancing Lathe Performance with Upgrades

Techniques and components for optimizing motor performance. Upgrading motor controls and accessories for better functionality.Upgrading your lathe can turn a good tool into a great one! One simple way to boost performance is by enhancing the motor. A stronger motor can increase cutting speed and accuracy. Don’t forget about motor controls! Better controls can make your machine easier to use. Think of it like giving your lathe a new set of wheels—it just rolls smoother!

| Upgrade Component | Benefit |

|---|---|

| High-torque motor | Increases power and speed |

| Digital control system | Improves precision and ease of use |

| Upgraded drive belts | Reduces vibration for a smoother operation |

Remember, these upgrades not only make your lathe better but can also save you time and frustration. Besides, a happy lathe means a happier you! And who doesn’t want that?

Safety Considerations When Using Metal Lathes

Essential safety protocols when operating floor mount lathes. Personal protective equipment (PPE) recommendations for tradesmen.Using a metal lathe can be fun, but safety must come first! Always wear personal protective equipment (PPE) like goggles, gloves, and ear protection. Lathes can be noisy and messy, and nobody wants shavings in their eyes. Keep your work area tidy to avoid slips or trips. Be aware of where your hands are; we need them for more than just waving at our friends! Lastly, always read the machine manual. Nobody likes surprises, especially from machines!

| PPE Item | Purpose |

|---|---|

| Safety Goggles | Protect eyes from flying debris |

| Gloves | Prevent cuts and scrapes |

| Ear Protection | Reduce loud noise exposure |

Real-World Applications of Floor Mount Metal Lathes

Examples of industries utilizing floor mount metal lathes. Case studies showcasing successful projects and innovations.Many industries rely on floor mount metal lathes for precision work. These machines help make important parts for cars, airplanes, and machines. For example, manufacturers often use them to cut metal to exact sizes. They also create custom tools and components. Success stories show how companies have improved efficiency and quality. Here are some industries that benefit:

- Automotive Manufacturing

- Aerospace Engineering

- Machinery Production

- Metal Fabrication

These sectors thrive on the accuracy and strength provided by floor mount lathes.

What industries use floor mount metal lathes?

Industries like automotive, aerospace, and machinery production utilize these tools effectively. They enhance production quality and streamline workflows, leading to better products.

Conclusion

In summary, a lathe floor mount metal lathe motor is essential for metalworking projects. It gives you power and precision in shaping materials. By knowing how to choose and use this motor, you can improve your skills. Explore more resources or ask experienced users for tips to enhance your learning. Start your next project today!FAQs

What Are The Key Specifications To Consider When Selecting A Motor For A Lathe Floor Mount Metal Lathe?When choosing a motor for a lathe, we should think about a few important things. First, check the motor’s power. You want enough power to do your work easily. Second, look at the speed options. Different tasks need different speeds, so adjustability is helpful. Finally, consider the motor’s size and how it fits on your lathe. A good fit helps it work better and last longer.

How Does The Power Output Of The Motor Affect The Performance Of A Floor-Mounted Metal Lathe?The motor’s power output tells us how strong it is. A strong motor can spin faster and cut metal better. If the motor is weak, it might slow down or struggle. This means you can finish your project faster and with more precision if you have a powerful motor. So, more power usually means better performance for the lathe!

What Are The Benefits Of Using A Variable Speed Motor For A Floor Mount Metal Lathe?Using a variable speed motor for a floor mount metal lathe helps you control the speed easily. This means you can go faster for some tasks and slower for others. You get better results and can work on different materials. It also makes your machine more efficient, so you use less energy. Overall, it helps you do a better job!

How Can Proper Motor Mounting Impact The Overall Stability And Accuracy Of A Lathe Operation?Proper motor mounting helps a lathe stay steady while it works. When the motor is fixed tightly, the lathe moves smoothly. This makes the cuts more precise and the shapes look nice. If the motor wobbles, it can make mistakes. So, strong mounting is key for a good job!

What Safety Precautions Should Be Taken When Installing Or Replacing A Motor On A Lathe Floor Mount Metal Lathe?When you install or replace a motor on a lathe, be very careful. First, always unplug the lathe before you start working. Wear safety goggles to protect your eyes from dust or small pieces. Make sure the area is clean and dry to avoid slipping. Lastly, ask a grown-up for help if you’re not sure what to do.