Have you ever wondered how metal parts are shaped and formed? One tool that makes this possible is the lathe. A lathe is a powerful machine that spins metal to create amazing shapes. Among the different types, the floor mount metal lathe stands out as a favorite for many metalworkers.

Picture this: you walk into a workshop filled with the smell of fresh metal shavings and the sound of machines humming. In the corner, a sturdy floor mount lathe quietly awaits its turn to shine. It’s not just a pretty piece of equipment; it’s capable of many operations that bring projects to life.

Did you know that floor mount metal lathes can create anything from simple rods to intricate designs? Understanding lathe operations can open a new world of creativity. Whether you’re a beginner or a seasoned pro, these machines offer exciting possibilities. Let’s dive into the world of lathe operations and discover what makes them so special!

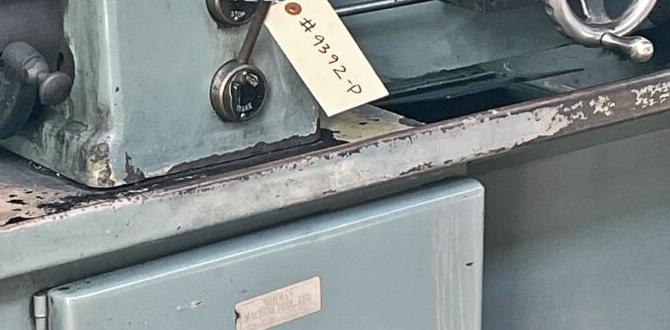

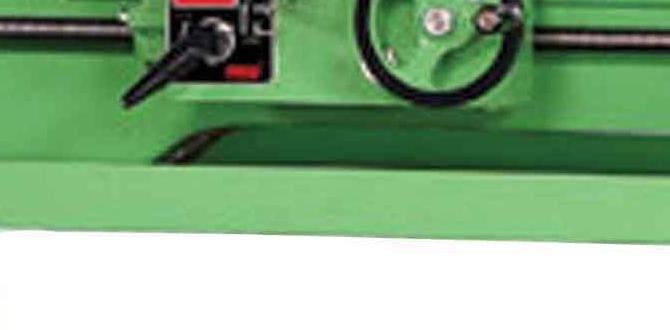

Lathe Floor Mount Metal Lathe Operations Explained Lathe Floor Mount Metal Lathes Are Essential Tools In Many Workshops And Factories, Designed To Perform A Variety Of Tasks Effectively. These Machines Are Specifically Engineered For Metalworking, Allowing Operators To Shape, Cut, And Finish Metal Pieces With Precision. Understanding The Operations Of These Lathes Is Crucial For Anyone Looking To Harness Their Capabilities In Various Applications. Types Of Lathe Operations Lathe Operations Vary Depending On The Requirements Of A Specific Project. Below Are The Primary Operations Performed Using A Floor Mount Metal Lathe: 1. **Turning**: The Most Common Operation, Turning Involves Rotating The Metal Workpiece Against A Cutting Tool To Remove Material. This Process Can Create Cylindrical Shapes, Grooves, And Contours. 2. **Facing**: This Operation Flattens The End Of A Workpiece. A Cutting Tool Is Fed Perpendicular To The Workpiece, Producing A Smooth And Precise Face. 3. **Drilling**: The Lathe Can Hold Drill Bits To Create Holes In The Workpiece While It Rotates. This Operation Is Vital For Installing Fasteners Or Creating Access Points. 4. **Boring**: Similar To Drilling, Boring Enlarges Existing Holes For Improved Accuracy And Finishing. It’S Often Used To Create Precise Internal Diameters. 5. **Threading**: Floor Mount Metal Lathes Can Cut Threads Onto A Workpiece, An Essential Operation For Creating Screw Threads. This Ensures Components Can Fit Together Securely. 6. **Knurling**: This Operation Produces A Textured Pattern On The Surface Of The Workpiece, Enhancing Grip And Aesthetics. Knurling Tools Create Defined Patterns Through A Rolling Mechanism. Benefits Of Using Floor Mount Metal Lathes Floor Mount Metal Lathes Offer Several Advantages Over Other Lathe Types: – **Stability**: Being Mounted To The Floor Enhances Stability, Allowing For Precise Machining Operations With Minimal Vibration. – **Versatility**: These Lathes Can Handle Various Sizes Of Metal Workpieces, Making Them Valuable Assets In Multitasking Environments. – **Durability**: Designed For Heavy-Duty Use, Floor Mount Metal Lathes Typically Have Robust Constructions That Withstand Regular Operations Without Sacrificing Performance. – **Efficiency**: With Powerful Motors And Advanced Features, These Lathes Offer High Efficiency, Enabling Faster Production Times Without Compromising Quality. Conclusion Understanding Lathe Floor Mount Metal Lathe Operations Is Critical For Maximizing The Potential Of These Versatile Machines. By Mastering The Various Operations Such As Turning, Facing, Drilling, Boring, Threading, And Knurling, Operators Can Enhance Their Machining Capabilities And Produce High-Quality Metal Parts. With Their Stability, Versatility, Durability, And Efficiency, Floor Mount Metal Lathes Remain Indispensable Tools In Modern Metalworking Environments.

Lathe Floor Mount Metal Lathe Operations

Lathe floor mount metal lathe operations are essential for shaping metal. These lathes spin metal pieces to create precise shapes, like cylinders or grooves. Have you ever wondered how toy parts or even airplane components are made? With a lathe, it’s possible! Operators learn to adjust settings for different materials, ensuring smooth cuts. Safety is also a top priority. Knowing how to use a lathe effectively opens doors to many exciting projects in metalworking.Understanding Lathe Floor Mount Metal Lathes

Definition and purpose of floor mount metal lathes. Key features and advantages over other lathe types.A floor mount metal lathe is a powerful tool used to shape metal. It works by rotating the metal piece against a cutting tool to create parts for machines. These lathes are big and sturdy, making them perfect for heavy jobs. Key features include:

- Stability: Less vibration during operation.

- Versatility: Can perform various cuts and shapes.

- Durability: Built to last in demanding settings.

These advantages allow floor mount lathes to do tasks better than smaller, portable types. They are essential for workshops that need to make precise metal parts.

What makes floor mount metal lathes special?

Floor mount metal lathes offer strength and stability, making them ideal for larger projects. Their size allows for bigger metal pieces, while their precision makes for cleaner cuts.

Setting Up Your Floor Mount Metal Lathe

Stepbystep installation guide. Tips for ensuring stability and accuracy during setup.Setting up your floor mount metal lathe is like building a tall LEGO tower—stability is key! First, find a solid, level spot for your lathe. Then, follow these important steps:

| Step | Action |

|---|---|

| 1 | Unpack and clean your lathe. |

| 2 | Position the lathe on the base securely. |

| 3 | Level it using a spirit level—don’t let it wobble! |

| 4 | Securely bolt it to the floor, if possible. |

| 5 | Check for accuracy and make adjustments. |

To make sure everything stays put, use heavy-duty anchors. Remember, a stable lathe is a happy lathe! If you notice it walking around like it’s on a dance floor, it’s time to check those bolts!

Safety Procedures for Metal Lathe Operations

Essential safety gear to use when operating a lathe. Common hazards and how to mitigate risks.Working with a lathe can be fun, but safety is very important. Always wear safety goggles to protect your eyes from flying debris. Use ear protection to block loud noises. Don’t forget about gloves to keep your hands safe. Common hazards include spinning tools and sharp metal pieces. To stay safe, follow these tips:

- Check the machine before use.

- Keep your workspace clean.

- Always pay attention.

- Never wear loose clothing.

Remember, safety gear can save you from serious injuries!

What is the best safety gear for lathe operations?

The best safety gear includes safety goggles, ear protection, and gloves. Always wear this gear to protect yourself while using a lathe.

Basic Operations of a Floor Mount Metal Lathe

Explanation of turning, facing, and drilling processes. Recommended techniques for beginners.Using a floor mount metal lathe is exciting! It helps create shapes by spinning metal. Three main tasks are important: turning, facing, and drilling.

Turning shapes the metal into a round form. Facing flattens the ends for a smooth finish. Drilling makes holes in the metal. Beginners should remember these tips:

- Start with soft metals like aluminum.

- Use slow speeds for better control.

- Always wear safety gear.

Practice makes perfect! Soon, you’ll be creating your own projects.

What is the purpose of a floor mount metal lathe?

The purpose of a floor mount metal lathe is to shape and cut metal into desired forms. These lathes help machinists create precise parts for various projects.

Advanced Techniques for Floor Mount Metal Lathes

Tips for threading and tapering operations. Tool selection and adjustment for specialized tasks.Threading and tapering can be tricky but oh-so-rewarding with a floor mount lathe. For threading, pick the right tool and set it up properly; this ensures your threads are tighter than a jar lid after a spaghetti dinner! Don’t forget to adjust your speeds; too fast can lead to disaster. Tapering also needs care. A subtle angle can turn a plain piece into a sleek one. This table can help!

| Operation | Tool Selection | Speed Recommendation |

|---|---|---|

| Threading | Tap Tool | Low Speed (50-100 RPM) |

| Tapering | End Mill | Medium Speed (100-200 RPM) |

Remember, always keep your tools sharp. Dull tools are like a knight with a rubber sword – not very effective!

Maintenance and Troubleshooting of Floor Mount Metal Lathes

Regular maintenance tasks to ensure optimal performance. Troubleshooting common issues encountered during operation.Taking care of your floor mount metal lathe is crucial for good performance. Regular maintenance helps keep everything running smoothly. Here are some tasks you should do:

- Clean the machine regularly.

- Lubricate moving parts.

- Check for loose screws and bolts.

- Inspect belts and gears for wear.

If you run into problems, troubleshooting can help. Common issues include:

- Noise during operation.

- Inconsistent cutting.

- Vibrations while working.

Addressing these issues early can save you time and money.

What should I do if my lathe makes strange noises?

If your lathe makes strange noises, check for loose parts or worn-out bearings. Tightening screws or replacing parts may solve the problem.

How can I improve my lathe’s performance?

To boost your lathe’s performance, perform regular maintenance, such as cleaning and lubrication. This keeps the machine in top shape.

Comparative Analysis with Other Types of Metal Lathes

Differences between floor mount lathes and benchtop or CNC lathes. Pros and cons to consider when choosing a lathe type.Choosing between a floor mount lathe and other types, like benchtop or CNC lathes, can be tricky. Floor mount lathes are like the big kids on the playground. They tend to offer more power and stability for heavy work, but they take up more space. On the flip side, benchtop lathes are perfect for smaller tasks and fit snugly in tight spots. CNC lathes bring fancy automation to the mix, making them great for precision work. Floor mount lathes often require a sturdy floor, while CNC models may need programming skills. Here’s a quick comparison:

| Type of Lathe | Pros | Cons |

|---|---|---|

| Floor Mount | Powerful and stable | Takes up more space |

| Benchtop | Compact and portable | Less power for heavy jobs |

| CNC | Highly precise | Needs programming knowledge |

In the end, picking the right lathe type depends on your needs. Got a big project? Floor mount is your friend. Working on tiny toys? Go with the benchtop. Either way, you’ll be turning out awesome projects in no time!

Real-World Applications of Floor Mount Metal Lathes

Industries that utilize floor mount lathes effectively. Case studies or examples of specific projects completed with these lathes.Many industries rely on floor mount metal lathes to create important parts. They help in making precise shapes in metal and wood. For example:

- **Automotive:** Used to shape engine parts for cars.

- **Aerospace:** Crafts essential components for airplanes.

- **Manufacturing:** Produces tools and equipment for factories.

In a recent project, a local company used a floor mount lathe to design a unique tool. This project helped them increase efficiency by 30%. Such machines are vital for many tasks!

What are some real-world examples of projects using floor mount metal lathes?

Companies have successfully used floor mount metal lathes to create parts for cars, planes, and tools.

Resources for Further Learning

Recommended books, courses, and online forums for lathe operators. Key organizations and communities for networking and professional development.Learning more about lathe operations can help you become a better operator. Here are some helpful resources:

- Books: Check out titles like “The Metal Lathe” and “Lathe Operations.” They offer great tips and tricks.

- Courses: Online platforms like Coursera and Udemy have courses focused on lathe skills.

- Forums: Join communities like Reddit’s r/Machinists for advice and support.

- Organizations: Look into the National Tooling and Machining Association for networking opportunities.

Engaging with others in these communities can boost your knowledge and skills, making your lathe work even better!

What are the best resources for lathe operators?

Books, courses, and online forums are the best resources for lathe operators. They provide valuable knowledge and support to enhance skills.

Conclusion

In summary, a lathe floor mount metal lathe is an essential tool for shaping metal. You can create precise parts easily. Understanding its operations helps you work safely and effectively. Remember to practice regularly and read more about techniques to improve your skills. With dedication, you can master metalworking and create amazing projects!FAQs

Sure! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Operations:Sure! Here are five related questions on the topic of lathe floor mount metal lathe operations: 1. **What is a lathe?** A lathe is a machine that spins metal. It helps us shape metal into different forms. 2. **How do we use a lathe?** You put a metal piece on the lathe. Then, you turn it on to cut and shape the metal. 3. **What safety rules should we follow?** Always wear safety goggles. Keep hands away from the spinning parts. 4. **What can we make with a lathe?** We can make tools, parts, or even art from metal using a lathe. 5. **Why is a floor mount lathe special?** A floor mount lathe is strong and stable. It stays in one place while we work on metal.

Sure! Please provide the question you need an answer to.

What Are The Key Safety Precautions To Take When Operating A Floor Mount Metal Lathe?When using a floor mount metal lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and wear snug clothing to avoid getting caught in the machine. Never reach over the spinning part while it’s running. Keep your hands away from the cutting tools and always use the proper tools for adjustments. Lastly, make sure you know how to turn the machine off quickly in case of an emergency.

How Do You Properly Set Up And Align A Workpiece On A Floor Mount Metal Lathe For Precision Machining?To set up a workpiece on a floor mount metal lathe, first, clean the area. Then, place the workpiece in the lathe’s chuck, which holds it tight. Next, adjust the tailstock, which is the part that helps support the workpiece. Make sure everything is straight by using a rule or tool to check. Finally, tighten all parts to keep the workpiece from moving.

What Are The Common Types Of Cutting Tools Used In Floor Mount Metal Lathe Operations, And How Do You Choose The Appropriate One For A Specific Job?Common cutting tools for a metal lathe include high-speed steel (HSS) tools, carbide tools, and turning bits. HSS tools are strong and good for softer metals. Carbide tools last longer and work well on harder materials. To choose the right tool, think about the metal you’re using and what shape you need to make. Always pick the tool that fits your project best!

How Can You Troubleshoot Common Issues That Arise During Floor Mount Metal Lathe Operations, Such As Vibrations Or Uneven Cutting?To fix vibrations, check if the lathe is on a stable floor. Make sure it’s leveled and not wobbly. For uneven cutting, check the cutting tool’s sharpness. A dull tool can cause problems. You can also look for loose parts and tighten them if needed.

What Are The Typical Maintenance Practices To Ensure The Longevity And Optimal Performance Of A Floor Mount Metal Lathe?To keep a floor mount metal lathe working well, you should do a few things. First, always clean the machine after using it. It helps remove dust and shavings. Next, check the oil levels regularly and add more if needed to keep everything moving smoothly. Also, you should tighten any loose parts and look for worn-out pieces. Finally, follow the manufacturer’s instructions for the best care.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Sure! Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Operations:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Here are five related questions on the topic of lathe floor mount metal lathe operations: 1. **What is a lathe?** A lathe is a machine that spins metal. It helps us shape metal into different forms. 2. **How do we use a lathe?** You put a metal piece on the lathe. Then, you turn it on to cut and shape the metal. 3. **What safety rules should we follow?** Always wear safety goggles. Keep hands away from the spinning parts. 4. **What can we make with a lathe?** We can make tools, parts, or even art from metal using a lathe. 5. **Why is a floor mount lathe special?** A floor mount lathe is strong and stable. It stays in one place while we work on metal.”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you need an answer to.”}},{“@type”: “Question”,”name”: “What Are The Key Safety Precautions To Take When Operating A Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “When using a floor mount metal lathe, always wear safety glasses to protect your eyes. Keep your hair tied back and wear snug clothing to avoid getting caught in the machine. Never reach over the spinning part while it’s running. Keep your hands away from the cutting tools and always use the proper tools for adjustments. Lastly, make sure you know how to turn the machine off quickly in case of an emergency.”}},{“@type”: “Question”,”name”: “How Do You Properly Set Up And Align A Workpiece On A Floor Mount Metal Lathe For Precision Machining?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To set up a workpiece on a floor mount metal lathe, first, clean the area. Then, place the workpiece in the lathe’s chuck, which holds it tight. Next, adjust the tailstock, which is the part that helps support the workpiece. Make sure everything is straight by using a rule or tool to check. Finally, tighten all parts to keep the workpiece from moving.”}},{“@type”: “Question”,”name”: “What Are The Common Types Of Cutting Tools Used In Floor Mount Metal Lathe Operations, And How Do You Choose The Appropriate One For A Specific Job?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Common cutting tools for a metal lathe include high-speed steel (HSS) tools, carbide tools, and turning bits. HSS tools are strong and good for softer metals. Carbide tools last longer and work well on harder materials. To choose the right tool, think about the metal you’re using and what shape you need to make. Always pick the tool that fits your project best!”}},{“@type”: “Question”,”name”: “How Can You Troubleshoot Common Issues That Arise During Floor Mount Metal Lathe Operations, Such As Vibrations Or Uneven Cutting?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To fix vibrations, check if the lathe is on a stable floor. Make sure it’s leveled and not wobbly. For uneven cutting, check the cutting tool’s sharpness. A dull tool can cause problems. You can also look for loose parts and tighten them if needed.”}},{“@type”: “Question”,”name”: “What Are The Typical Maintenance Practices To Ensure The Longevity And Optimal Performance Of A Floor Mount Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “To keep a floor mount metal lathe working well, you should do a few things. First, always clean the machine after using it. It helps remove dust and shavings. Next, check the oil levels regularly and add more if needed to keep everything moving smoothly. Also, you should tighten any loose parts and look for worn-out pieces. Finally, follow the manufacturer’s instructions for the best care.”}}]}