Have you ever wondered how parts are made with incredible precision? A lathe floor mount metal lathe is a tool that helps create such parts. It might sound complex, but it’s built for everyone, including beginners. You can easily make screws, bolts, and other threaded parts using this amazing machine.

Imagine needing a special part for a project. You could go to a store or, even better, make it yourself. The threading dial on a lathe simplifies this task. It helps you cut threads accurately every time. With this tool, you can turn your ideas into reality.

Fun fact: many engineers and hobbyists use lathes to build everything from toys to car parts! This machine plays a vital role in many industries. You might be surprised to discover how versatile a lathe can be. Ready to dive into the world of metalworking? Let’s explore the ins and outs of lathe floor mount metal lathes and their threading dials!

Lathe Floor Mount Metal Lathe Threading Dial: A Guide

Understanding Lathe Floor Mount Metal Lathe Threading Dial

The lathe floor mount metal lathe threading dial helps in precise threading. It shows the exact location of the thread, making it easier to create consistent cuts. Have you ever struggled to make straight lines? This tool can make your work much neater. A surprising fact is that accurate threading can enhance the strength of your projects. With this tool, your projects can turn out perfect every time. Using a lathe with a working threading dial is essential for any metalworker aiming for high-quality results.Understanding Lathe Floor Mount Metal Lathes

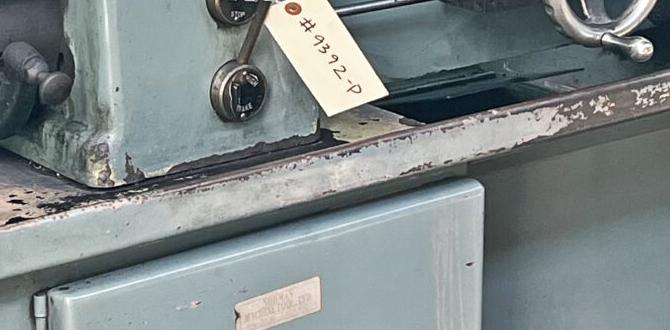

Definition and purpose of a floor mount metal lathe. Key features and benefits of using a floor mount lathe.A floor mount metal lathe is a powerful tool that helps create precise metal parts. It stands firmly on the ground, making it stable and easy to use. Think of it as a magician’s wand for metalwork. Key features include a strong motor and adjustable speeds, allowing users to craft items like gears and shafts. Benefits? You’ll save time and get amazing results. Plus, it might even impress your friends! Who knew making metal could be so cool?

| Feature | Benefit |

|---|---|

| Sturdy Design | Stable operation & precise cuts |

| Adjustable Speeds | Versatile for different projects |

| Powerful Motor | Efficient machining of tough materials |

The Importance of the Threading Dial

Explanation of what a threading dial is. Role of the threading dial in achieving precise threading.A threading dial is an important tool for lathes. It helps you make precise threads on metal pieces. When you want to create a thread, the dial shows the right timing to engage the leadscrew. This ensures that your threads line up perfectly. Without it, you might end up with uneven or crooked threads. The threading dial is a small but mighty part for getting your projects right!

What is a threading dial?

A threading dial helps you measure and align threads accurately. It allows for clear readings as you work.

How does it help with precise threading?

- Improves accuracy: It shows when to move the tool for perfect threads.

- Reduces mistakes: Clear timing helps avoid misalignment.

- Enhances efficiency: Saves time by making threading easier.

Types of Threading Dials

Comparison of different threading dial designs. Discussing the advantages and disadvantages of each type.Threading dials come in different designs, each with unique benefits and downsides. For example, a single-stud dial is simple and easy to use. However, it may not offer precise alignment. On the other hand, a double-stud dial provides better accuracy but can be harder to adjust. Here’s a quick comparison:

- Single-Stud Dial: Easy to use, but less precise.

- Double-Stud Dial: More accurate, but tricky to adjust.

- Manual Dial: Affordable and trusty, but requires careful handling.

Choose wisely based on your needs!

What are the types of threading dials?

There are mainly three types: single-stud dials, double-stud dials, and manual dials.

Why choose one type over another?

It depends on your project. If you want simplicity, go for a single-stud dial. If you need precision, pick the double-stud dial. A manual dial works great if you’re budget-savvy.

How to Install a Threading Dial on a Floor Mount Lathe

Stepbystep installation process. Common mistakes to avoid during installation.Installing a threading dial on your lathe can be like baking a cake: follow the steps, avoid the messy mistakes, and you’ll be a pro in no time! First, secure the dial onto the lathe with the right screws. Next, attach it near the carriage for easy access. Remember, it goes on the front side where you can see it clearly. A common slip is not aligning it correctly—this could make your threads go wonky! Double-check your work to keep everything in line.

| Step | Tip |

|---|---|

| 1. Prepare tools | Make sure you have all screws and a screwdriver handy. |

| 2. Attach the dial | Position it carefully for a clear view. |

| 3. Check alignment | Align properly to avoid mistakes! |

Remember, measure twice, screw once! Happy threading!

Using the Threading Dial Effectively

Techniques for accurate measurements and settings. Tips for troubleshooting threading issues.To use the threading dial accurately, follow these techniques:

- Always check your measurements before starting.

- Make sure the dial is properly calibrated.

- Use slow, steady movements for precise cuts.

If you face threading issues, here are quick fixes:

- Inspect the tool for wear or damage.

- Adjust your speed if the threads are rough.

- Ensure proper alignment of the lathe and workpiece.

These tips make using the threading dial easier and can help you achieve better results!

What common problems occur while using a threading dial?

Common problems include uneven threads, tool slipping, and incorrect measurements. Each of these can lead to poor results and frustration.

Maintenance of Threading Dials

Routine maintenance checks and procedures. How to ensure longevity and performance of the threading dial.Keeping your threading dial in great shape is important. Regular checks make it last longer and work better. Here are some easy steps:

- Wipe dust and dirt away each week.

- Check for oil or lubrication every month.

- Look for signs of wear or damage.

- Adjust it for proper alignment as needed.

- Store it in a dry place when not in use.

These simple tips can improve its performance and lifespan.

How can I maintain my threading dial?

To maintain your threading dial, check it regularly. Keep it clean and lubricated. This helps avoid wear and keeps it running smoothly. Protect it from moisture too. Regular care will keep it working well for years.

Upgrading Your Floor Mount Lathe

When to consider upgrading your threading dial. Suggested upgrades and their benefits.Upgrading parts of your lathe can make a big difference. If your threading dial is hard to read or use, it may be time to replace it. Consider these upgrades:

- Digital dials: These make it easy to see measurements.

- Improved gears: Stronger gears create smoother movements.

- Large dials: Bigger dials are easier to handle and read.

Benefits of an upgrade can include better accuracy and less frustration. These changes can help you work faster and create better results.

When should you upgrade your threading dial?

If you notice problems with your current threading dial, **it’s time to consider an upgrade**. Hard-to-read markings can slow you down. A new dial can make your work easier and more enjoyable.

Comparisons with Other Lathe Models

Distinctions between floor mount and other lathe types. Advantages of choosing a floor mount metal lathe for threading operations.Floor mount lathes stand out from other models like bench or mini lathes. Their sturdy design gives more support, making them great for heavy materials. For threading operations, they offer precision that smaller lathes can’t match. Users often find that a floor mount metal lathe provides easier control and smoother operation. Choosing this type helps avoid many common issues found with other lathes.

Why Choose a Floor Mount Lathe?

Floor mount lathes excel in stability and precision. This makes them the go-to choice for threading.

- Greater stability

- Higher precision for threading

- Better handling of heavy materials

Frequently Asked Questions about Floor Mount Lathe Threading Dials

Common inquiries and their detailed answers. Clarifications on misconceptions regarding threading dials and lathe operations.Many people have questions about floor mount lathe threading dials. One common question is, “What does a threading dial do?” It helps you keep track of your cuts, making threading easier and more precise. Some think it’s just a fancy gadget, but it’s important! Another question is, “Is it necessary for all lathes?” Not all lathes need one, but it sure makes life easier! Don’t worry; you won’t need a PhD to master it. Just remember: it’s about teamwork between your machine and the threading dial!

| Question | Answer |

|---|---|

| How do I use a threading dial? | Align the dial, make your cut, and follow the numbers! |

| Can I use it for other projects? | Yes! It’s great for any threaded work! |

Conclusion

In conclusion, a lathe floor mount metal lathe with a threading dial is great for precise metalworking. It helps you create accurate threads easily. Make sure to choose a model that fits your needs. You can practice your skills and improve your projects. For more information, consider reading guides or watching tutorials on using a lathe effectively!FAQs

Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Threading Dials:Sure! A lathe is a tool that spins metal to shape it. The threading dial helps you make threads, which are spiral grooves on metal pieces. It shows you when to move the tool for perfect threads. Using the threading dial makes your work easier and neater. Always be careful when working with a lathe!

Sure! Please provide the question you want me to answer, and I’ll help you with that.

What Is The Primary Function Of A Threading Dial On A Floor-Mounted Metal Lathe?The threading dial helps you create threads on a metal piece. Threads are the little ridges that help screws fit together. You turn the dial to match the machine’s movements. This makes threading easier and more accurate for you. It helps ensure that the threads are just right for the job!

How Does A Threading Dial Help In Achieving Accurate Thread Cuts During The Machining Process?A threading dial helps you cut threads accurately when you use a lathe machine. It shows you the right spot to start making threads. When you see the right number on the dial, you can turn the machine just right. This way, you make sure the threads fit nicely every time.

What Are The Different Types Of Threading Dials Available For Metal Lathes, And How Do They Differ In Operation?There are two main types of threading dials for metal lathes: direct and indirect. With a direct threading dial, you can see the numbers clearly as you turn the tool. It helps you quickly find the right spot to start cutting. An indirect threading dial is a bit different. You have to count the lines and follow a special pattern, which can be trickier. Both types help you make sure the threads on metal pieces are just right!

How Can Proper Calibration Of The Threading Dial Impact The Precision Of Thread Cutting On A Lathe?Calibrating the threading dial helps you make accurate threads on a lathe. If it’s not set right, your threads can be uneven or too loose. This means the parts won’t fit together well. When you adjust it correctly, you get clean and tight threads. This makes your work look good and work better!

What Are Some Common Troubleshooting Steps If The Threading Dial On A Metal Lathe Is Not Functioning Correctly?If the threading dial on your metal lathe isn’t working, start by checking the power. Make sure the lathe is plugged in and switched on. Next, look for any dirt or debris on the dial. Clean it if you see anything. Lastly, check the threading gears to ensure they are not damaged or loose. If these steps don’t help, ask an adult for further assistance.

{“@context”:”https://schema.org”,”@type”: “FAQPage”,”mainEntity”:[{“@type”: “Question”,”name”: “Here Are Five Related Questions On The Topic Of Lathe Floor Mount Metal Lathe Threading Dials:”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! A lathe is a tool that spins metal to shape it. The threading dial helps you make threads, which are spiral grooves on metal pieces. It shows you when to move the tool for perfect threads. Using the threading dial makes your work easier and neater. Always be careful when working with a lathe!”}},{“@type”: “Question”,”name”: “”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Sure! Please provide the question you want me to answer, and I’ll help you with that.”}},{“@type”: “Question”,”name”: “What Is The Primary Function Of A Threading Dial On A Floor-Mounted Metal Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “The threading dial helps you create threads on a metal piece. Threads are the little ridges that help screws fit together. You turn the dial to match the machine’s movements. This makes threading easier and more accurate for you. It helps ensure that the threads are just right for the job!”}},{“@type”: “Question”,”name”: “How Does A Threading Dial Help In Achieving Accurate Thread Cuts During The Machining Process?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “A threading dial helps you cut threads accurately when you use a lathe machine. It shows you the right spot to start making threads. When you see the right number on the dial, you can turn the machine just right. This way, you make sure the threads fit nicely every time.”}},{“@type”: “Question”,”name”: “What Are The Different Types Of Threading Dials Available For Metal Lathes, And How Do They Differ In Operation?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “There are two main types of threading dials for metal lathes: direct and indirect. With a direct threading dial, you can see the numbers clearly as you turn the tool. It helps you quickly find the right spot to start cutting. An indirect threading dial is a bit different. You have to count the lines and follow a special pattern, which can be trickier. Both types help you make sure the threads on metal pieces are just right!”}},{“@type”: “Question”,”name”: “How Can Proper Calibration Of The Threading Dial Impact The Precision Of Thread Cutting On A Lathe?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “Calibrating the threading dial helps you make accurate threads on a lathe. If it’s not set right, your threads can be uneven or too loose. This means the parts won’t fit together well. When you adjust it correctly, you get clean and tight threads. This makes your work look good and work better!”}},{“@type”: “Question”,”name”: “What Are Some Common Troubleshooting Steps If The Threading Dial On A Metal Lathe Is Not Functioning Correctly?”,”acceptedAnswer”: {“@type”: “Answer”,”text”: “If the threading dial on your metal lathe isn’t working, start by checking the power. Make sure the lathe is plugged in and switched on. Next, look for any dirt or debris on the dial. Clean it if you see anything. Lastly, check the threading gears to ensure they are not damaged or loose. If these steps don’t help, ask an adult for further assistance.”}}]}